3D printing has long since transitioned from a niche hobby to a mainstream creative outlet, enabling makers, hobbyists, and professionals to materialize ideas in a matter of hours. Two popular contenders in the mid-range segment, the Creality K1C, and the Anycubic Kobra 3 Combo, represent the latest evolutions from brands that have consistently pushed boundaries in desktop 3D printing. Creality aims to bring high-speed CoreXY performance to the prosumer market, while Anycubic continues to refine its proven i3-based models with user-friendly features. Both machines promise reliable results and advanced functionalities, yet their underlying designs and target audiences diverge in significant ways. Understanding their historical evolution, distinct build characteristics and real-world performance is key to deciding which 3D printer best suits a user’s needs.

From Unknown Upstarts to Global Icons: The Surprising Rise of Creality and Anycubic

The journey of Creality as a major 3D printer manufacturer began with the Ender series, which rapidly garnered popularity in the late 2010s. The Ender 3, in particular, struck an unprecedented balance between affordability and capability, influencing a wave of budget machines that followed. Over time, Creality expanded its lineup with the CR series and various special editions, each iteration refining the core design and adding options like automatic bed leveling and improved extruders. When faster printing and better motion systems became the industry’s next frontier, Creality responded with its K series. The K1C represents a leap forward, employing a CoreXY design with a rigid metal frame and an emphasis on high-speed, high-flow printing.

Anycubic, meanwhile, emerged around the same period with a similarly keen focus on affordability and user experience. Their early i3-style designs—most notably the Mega series—made 3D printing more approachable to novices by prioritizing quick assembly and consistency. As the community demanded more advanced yet streamlined features, Anycubic introduced the Kobra line, integrating direct drive extruders and improved leveling systems while maintaining that user-friendly ethos. The Kobra 3 Combo builds upon these foundations, reflecting Anycubic’s years of iterative refinement in i3 architecture, as well as their desire to include modular or “combo” elements such as improved filament handling and an optional enclosure. This historical backdrop sets the stage for the fundamental differences in philosophy and design between the K1C and the Kobra 3 Combo.

Unboxing Drama: Which 3D Printer Gets You Printing Faster?

When first unboxing the Creality K1C, users typically encounter a partially assembled, box-style frame that hints at its CoreXY heritage. The metal structure often arrives with some panels pre-installed, or at least partially so, to facilitate an enclosed or semi-enclosed environment. This design choice is intended to help maintain stable internal temperatures and reduce vibration at higher speeds. Setting it up usually entails attaching the remaining panels, connecting a few cables, and calibrating through an onboard routine. Creality has enhanced bed-leveling with a sensor-based system, which reduces the traditional trial-and-error that used to frustrate many beginners.

In contrast, the Anycubic Kobra 3 Combo preserves the open i3-style setup but modernizes it with reinforced metal profiles and a direct drive extruder system. Assembly is straightforward, often requiring just a handful of screws to secure the gantry to the base, plus a few cable connections. The “Combo” designation implies that there may be optional add-ons like an enclosure kit or integrated filament sensors, but these modules are usually designed to install seamlessly. Anycubic’s LeviQ auto-leveling routine streamlines bed calibration further, making it a boon for newcomers. Within an hour or so, most users can be up and running, ready to print sample models on the Kobra 3 Combo.

Speed Wars vs. Accuracy Battles: Unpacking Real Print Performance

Differences in motion systems underscore the divergent priorities of the Creality K1C and the Anycubic Kobra 3 Combo. By embracing a CoreXY design, the K1C can achieve impressive speeds often advertised in the range of 400 to 600 mm/s, though real-world users tend to find the sweet spot closer to 200–300 mm/s for complex prints. The rigid enclosure and metal frame minimize wobble and resonance during high acceleration, crucial for maintaining print quality when you push the machine to its limits. This advantage particularly benefits advanced users who require rapid prototyping or short turnaround times. The K1C also incorporates a high-flow hotend that helps sustain faster extrusion rates, meaning it can consistently push out filament at high speed without clogging or under-extrusion.

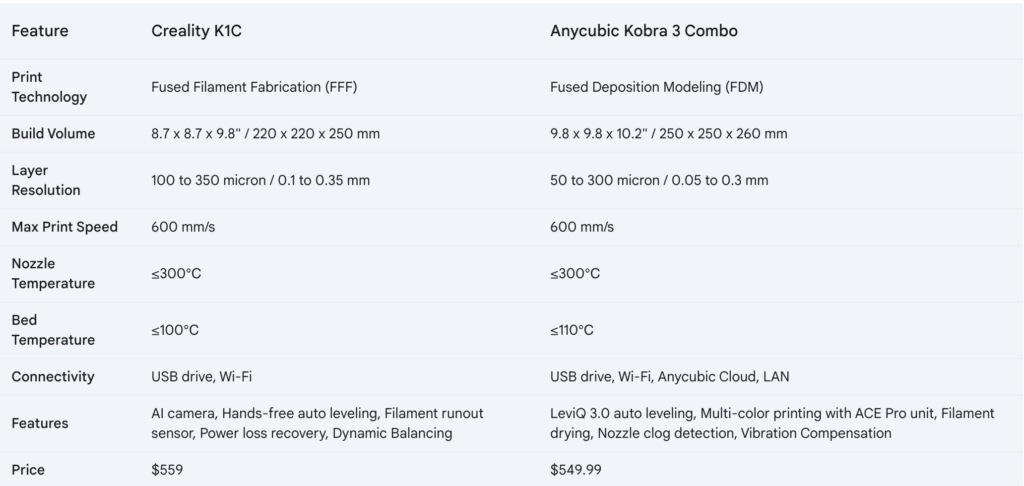

Specifications

Anycubic’s Kobra 3 Combo is more conservative on paper, typically aiming for speeds up to 250 mm/s. While that number may be outpaced by the K1C, the reliability and consistency it provides at moderate speeds are appealing to many hobbyists. The i3-style motion system is well-understood, and it’s easy to dial in slicer settings for optimal layer alignment and minimal stringing. The direct drive extruder excels at flexible filaments, such as TPU, ensuring that those who want to experiment with exotic materials can do so without major hassles. In practical terms, the Kobra 3 Combo delivers a stable, predictable experience, making it a solid choice for users who value ease of use and consistent performance over top-end speed.

In side-by-side test prints, the K1C often wins for raw throughput, finishing sizeable objects faster. However, the Kobra 3 Combo holds its own in precision and surface finish, especially on smaller, detail-oriented models where speed is less critical. Both machines are capable of impressive results, provided you calibrate them carefully and select suitable slicer profiles.

The Real-World Test: How These Printers Shine (or Flop) in Daily Use

In a professional prototyping environment, the Creality K1C’s ability to sprint through large prints can be a game-changer. Industrial designers, engineers, or small-scale manufacturers who iterate frequently may appreciate how quickly a CoreXY machine can pump out revisions. This speed advantage becomes especially useful for production runs of functional parts, such as brackets or jigs, where shaving hours off each job leads to notable time savings. The partially enclosed design also helps maintain stable temperatures for materials like ABS or Nylon, making it a flexible platform for more demanding applications.

For educational settings, home workshops, or maker spaces that serve beginners and casual users, the Anycubic Kobra 3 Combo’s straightforward assembly and dependable performance often translate into less downtime and fewer maintenance hurdles. Instructors can focus on the principles of 3D printing rather than constant troubleshooting, while families or hobbyists can enjoy a dependable machine that produces high-quality prints at manageable speeds. The open i3 format also simplifies upgrades, so if users want to swap out nozzles or try different bed surfaces, they can do so without navigating the complexities of a fully enclosed system. In practice, the choice often comes down to balancing the desire for rapid production with the need for ease of use and proven reliability.

Final Face-Off: Choosing Your Champion in the 3D Printing Arenasignificant

Deciding between the Creality K1C and the Anycubic Kobra 3 Combo ultimately hinges on the user’s priorities. The K1C stands out as a high-speed CoreXY workhorse capable of turning around large projects swiftly while maintaining admirable print quality. Its partially enclosed design offers better heat control and is bolstered by Creality’s large modding community, which can be invaluable for those who enjoy pushing their printers to the limit. The Kobra 3 Combo, on the other hand, excels in simplicity and accessibility. Anycubic has taken a proven i3 platform and refined it to offer beginner-friendly assembly, intuitive leveling systems, and consistent results. This approach is especially attractive for users who value a stable, dependable machine that can handle a wide range of materials without a steep learning curve. Both printers reflect their makers’ histories of innovation, leaving the choice to what you value most: blazing speed or day-to-day reliability.