By using 3D Printing Technology, hobbyists can use 3D printers to create a variety of objects, from tools to toys, that they can use in their everyday lives. 3D Printing Technology and the hobbyist community have significantly impacted how we interact with the world around us.

From building furniture to creating complex pieces of art, the possibilities are endless for 3D Printing Technology. We will discuss the basics of FDM 3D Printing Technology and how hobbyists can use this technology to create unique and interesting objects.

How does an FDM 3D Printer Work?

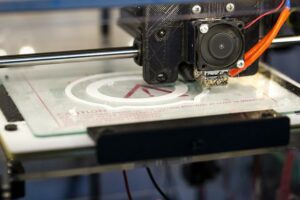

FDM 3D printers work by extruding filament through a heated nozzle to build up layers of plastic. The process begins with the printer heating up the filament to its melting point.

The FDM 3D printer is the most popular type of 3D printer. It works by building up an object layer by layer from the bottom up. Each layer is a thinly sliced horizontal cross-section of the final object. The layers are bonded together as they are printed, typically using heat and pressure.

The FDM 3D printing process

If you’ve been curious about how FDM 3D printers work or are considering buying one for your office, this blog post is for you. I’m going to explain the inner workings of FDM technology so that you can make an informed decision about whether or not it’s right for you.

FDM 3D Printing Technology FDM, or Fused Deposition Modeling, is a type of 3D Printing Technology that Stratasys developed in the early 1990s.

Today, FDM is the most commonly used type of 3D Printing Technology. FDM works by extruding a string of thermoplastic filament from the nozzle of a 3D Printer’s extruder head onto a build platform.

FDM 3D printers work by depositing a filament of thermoplastic material, layer by layer, to build up an object. The filament is fed from a spool through a heated extruder head, which melts the plastic and deposits it in very thin layers (usually just 0. 1 mm thick). Once each layer has been deposited, the print bed lowers, and another layer is printed on top. This process continues until the object is complete.

Advantages of FDM

- Inexpensive to buy.

- Cheap to maintain (filament is cheap). Works with a range of materials.

- Good for printing large parts. Disadvantages of FDM Technology

- Inferior accuracy.

- Low-quality surface finish.

- Poor layer adhesion.

The benefits of using an FDM 3D printer

In office settings, time is often of the essence. That’s why having a reliable and quick method for prototype creation is essential. And that’s where FDM 3D printers come in.

These machines can create three-dimensional objects from digital models in a matter of minutes, saving valuable time in the design process. Not only are they fast, but FDM 3D printers are also relatively inexpensive, making them an excellent option for small businesses or start-ups.

From the boardroom to the classroom, FDM 3D printers can be utilized in a variety of environments. For instance, students can use these printers to create prototypes of projects that they are working on in the classroom. Teachers can also use these devices to create helpful classroom aids and handouts.

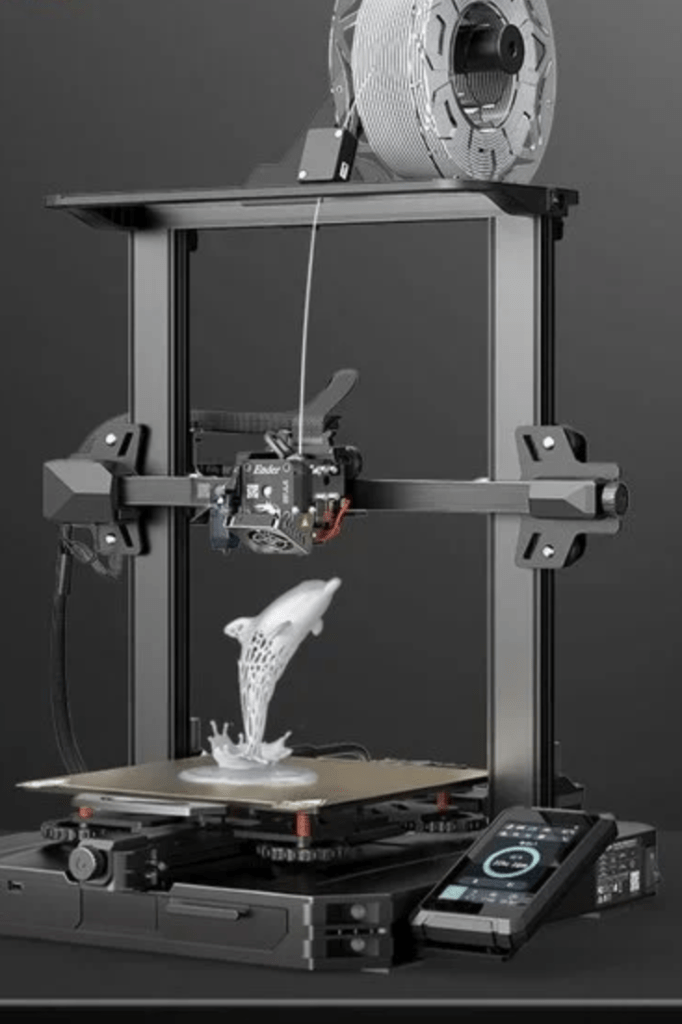

The CREALITY Ender-Series 3D Printer is an excellent choice for anyone getting started with 3D printing. I recently purchased the latest machine and am incredibly excited.

The printer is incredibly easy to set up and use, with a detailed user manual and lots of helpful online resources. The printer is incredibly precise, producing excellent-quality prints with very few problems.

And the price is unbeatable. Even with the added cost of filament, it’s much more affordable than any other comparable 3D printer I’ve looked at. I highly recommend it to anyone interested in 3D printing.

The CREALITY Ender Series is another affordable, reliable 3D printer ideal for more experienced hobbyists, tinkerers, and educators. It features a heated aluminum print bed and a comprehensive array of features to help you get the most out of your 3D printing experience.

With a simple assembly process, strong construction from durable materials, and a responsive customer support team, the CREALITY Ender series is ideal for those who want a reliable 3D printer without breaking the bank.

Are you ready to explore the possibilities of 3D printing? Check them out; it is free to see!

Thanks,

Bullwinkle