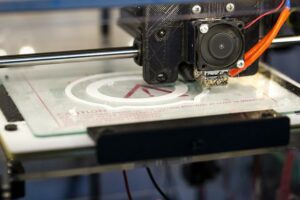

3D printing, or additive manufacturing, has come a long way since its inception in the 1980s. What started as a method for rapid prototyping has evolved into a powerful tool that’s integral to various industries, from automotive to aerospace to healthcare. Through layers upon layers of material, three-dimensional objects are created, often with complex geometries that traditional manufacturing methods struggle to replicate.

While early 3D printing primarily employed plastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), advancements in the field have pushed the boundaries of what materials can be used. Plastics were just the tip of the iceberg; the possibilities for materials have expanded to include metals, ceramics, and even biomaterials. This evolution has broadened the applications and capabilities of 3D printing, making it an indispensable part of modern manufacturing.

The importance of these advanced materials can’t be understated. They’re not just enhancing the strength, flexibility, and durability of printed objects but are also paving the way for entirely new applications that were previously unimaginable. From creating lightweight yet robust aerospace components to developing patient-specific medical implants, advanced materials are turning visionary ideas into reality.

Understanding this revolution begins with appreciation. With new materials, we can now create previously deemed impossible with traditional methods. This shift is about more than just innovation; it’s about redefining what’s possible, spurring new industries, and ultimately, changing how we manufacture and interact with the world around us.

Understanding Advanced 3D Printing Materials

Advanced 3D printing materials represent a significant leap from their traditional counterparts. While early 3D printing heavily relied on basic polymers like ABS and PLA, advanced materials now include an exciting range of high-performance polymers, metals, ceramics, and composites, each bringing unique properties and benefits to the table.

High-performance polymers, for instance, offer enhanced strength, flexibility, and resistance to heat and chemicals. These characteristics make them ideal for applications requiring durable and resilient components. Metals used in 3D printing, such as titanium and stainless steel, add another dimension of strength and precision, making them perfect for industries like aerospace and automotive.

Ceramics utilized in 3D printing are coveted for their heat resistance and durability, making them suitable for both industrial and consumer applications. Composites, combining multiple materials, provide a harmonious balance of the best traits of each component, thus delivering unmatched performance.

K1 SE 3D Printer

So, what sets advanced materials apart? Their unique properties come into play in high-stakes applications where failure isn’t an option. Unlike traditional materials, advanced options handle extreme conditions, complex stressors, and specialized requirements. For instance, dental and medical fields benefit significantly from biomaterials, allowing for customized, patient-specific solutions that enhance the quality of care. 50% off Get 2KG PLA Filament

Knowing which material to use depends on the application’s demands. High-performance polymers might be suitable for electronics components requiring insulation and durability, while metals may be necessary for load-bearing parts in engineering projects. Ceramics could be the go-to for high-temperature environments, and composites might provide the essential balance for applications needing a blend of attributes.

Navigating the world of advanced 3D printing materials means understanding these nuances. It involves recognizing that the material you choose directly impacts the final product’s reliability, functionality, and efficiency. As the landscape of 3D printing continues to evolve, staying informed about the latest materials and their capabilities becomes increasingly important. This knowledge enables us to push boundaries further, bringing groundbreaking innovations to life.

High-Performance Polymers: Strength and Flexibility

High-performance polymers have emerged as essential materials in the evolution of 3D printing, unlocking enhanced strength and flexibility. These polymers are engineered to meet demanding industry standards, making them invaluable in countless applications.

Materials like PEEK (Polyether Ether Ketone) and ULTEM (Polyetherimide) exemplify the power of these advanced polymers. PEEK is known for its exceptional thermal and chemical resistance, which is why it’s often used in the aerospace and automotive industries. ULTEM, on the other hand, offers fantastic strength-to-weight ratios, which are ideal for complex engineering solutions.

The versatility of high-performance polymers allows them to be used across a range of industries. For example, in the medical field, these materials create durable, biocompatible implants, while in aerospace, they contribute to lightweight, robust components. Their flexibility isn’t just physical; it extends to their applications, making them the go-to choice for innovative solutions.

Case studies illuminate the real-world impact of these materials. Consider the medical device industry, where PEEK has been used to develop custom spinal implants tailored to the unique anatomy of each patient. These implants are not only strong and durable but also reduce the risk of rejection. In the aerospace sector, ULTEM has enabled the development of complex parts that can withstand extreme conditions, offering long-lasting performance without adding significant weight.

Choosing the appropriate high-performance polymer involves understanding the specific requirements of your application. Consider factors like thermal stability, chemical resistance, and mechanical strength. Doing so ensures the final product will meet or exceed expectations, providing reliability and longevity in its intended use.

For anyone involved in 3D printing, staying updated on the latest high-performance polymers is more than just a recommendation—it’s a pathway to continuous innovation. Keeping an eye on new developments and emerging materials can help you leverage the full potential of 3D printing, pushing the limits of what’s possible in your projects.

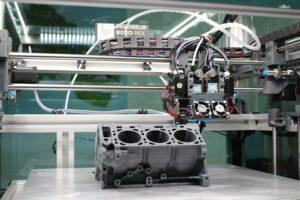

Metal Additive Manufacturing: Precision and Strength

Metal additive manufacturing, a cornerstone of modern industrial applications, has transformed how we approach precision and strength. Unlike traditional manufacturing methods that often involve subtracting material to shape a part, metal 3D printing builds components layer by layer, allowing for unparalleled accuracy and material efficiency.

The evolution of metal 3D printing is fascinating. Initially, metals like titanium and aluminum were adopted for their beneficial properties, such as being lightweight, high strength, and resistant to corrosion. Over time, the range of printable metals has expanded to include stainless steel, cobalt-chrome, and even precious metals like gold and platinum. Each material brings its own set of advantages and opens new doors for intricate designs and robust applications.

Various industries have embraced metal additive manufacturing. Aerospace leads the pack, utilizing lightweight yet strong materials to make everything from engine parts to airframe components. This technology has also found a home in the automotive industry, where the ability to produce high-strength, lightweight parts directly impacts performance and fuel efficiency. Additionally, the medical field benefits significantly from custom implants and surgical tools that metal 3D printing can produce. These parts often fit better and work more effectively than those made with traditional methods.

Navigating the challenges specific to metal 3D printing is critical for anyone looking to use this technology. Common issues include managing residual stresses, potential warping during the cooling process, and the need for post-processing to achieve the desired surface finish. Understanding these challenges can help you develop strategies to mitigate them, ensuring high-quality results.

Choosing the right metal for your project depends on various factors, including the specific requirements of your application, cost considerations, and the trade-offs between weight and strength. By carefully selecting the appropriate metal, you can maximize the benefits of metal additive manufacturing and push the boundaries of innovation.

Metal 3D printing isn’t just about making parts; it’s about redefining the possibilities of design and engineering. As we continue to explore its capabilities, staying informed about the latest advancements and techniques will empower you to create more efficient, effective, and groundbreaking products.

Biomaterials: Bridging Healthcare and Manufacturing

Biomaterials have become a game-changer for both the healthcare and manufacturing sectors. These are materials that can interact with biological systems, opening up extraordinary possibilities that were once the realm of science fiction.

Medical and dental applications are at the forefront of biomaterial use. Custom dental implants, made from biocompatible materials, offer solutions that merge with the body seamlessly. Think of joint replacements and coronary stents crafted specifically for an individual’s anatomy—they function better and last longer.

One of the most exciting developments in this area is bioprinting. Using cells and biocompatible materials, researchers are now able to print tissues, and they are even working towards printing entire organs. Imagine the impact on organ transplant lists and the potential to eliminate the problem of organ rejection. The future could see patients receiving 3D-printed organs that are a perfect genetic match.

Ethical considerations and regulatory hurdles are significant but necessary factors in this space. The promise of bioprinting organs raises questions about the moral implications and the need for rigorous clinical and ethical guidelines. Staying updated on regulatory changes and ethical debates will ensure responsible advancements in the field.

For healthcare professionals and researchers, understanding and leveraging biomaterials can significantly impact patient care. Customization and precision in medical treatments lead to higher success rates and better patient outcomes. The key is remaining informed about the latest research and breakthroughs, enabling a proactive approach to integrating biomaterials into practice.

Navigating through these advancements means appreciating the delicate balance between innovation and regulation. Staying on top of emerging technologies and their ethical implications will guide you toward more effective and responsible use of biomaterials in healthcare and manufacturing.

Ceramic 3D Printing: Heat-Resistant and Durable

Ceramic 3D printing has carved out a niche for itself with its unique properties of heat resistance and durability. Unlike metals and polymers, ceramics can withstand extremely high temperatures without losing their structural integrity, making them invaluable in high-stress environments.

Types of ceramics such as zirconia, alumina, and silicon carbide are commonly used in 3D printing. These materials excel in conditions where metals and polymers might fail. For example, zirconia is often employed in applications requiring insulation and resistance to thermal shock, while alumina is known for its wear resistance and electrical insulating properties.

Industrial applications of ceramic 3D printing are vast. In electronics, it is used to create intricate components that must perform reliably in high-temperature environments—aerospace benefits from ceramic parts that need to endure extreme heat and mechanical stress. Even consumer products like jewelry and home décor have harnessed the aesthetic and functional qualities of ceramic 3D printing.

Traditional ceramic manufacturing processes like casting and sintering can be time-consuming and complex. 3D printing streamlines these processes, allowing for faster production times and more intricate designs. This speed and flexibility make ceramic 3D printing an attractive option for rapid prototyping and limited-run applications.

Innovative uses of ceramics extend to fields such as healthcare, where bioceramics are used for bone repair and dental applications due to their biocompatibility and resemblance to natural bone structure. In the energy sector, ceramic components are critical in high-efficiency engines and turbines, offering longevity and robust performance under extreme conditions.

Choosing the right type of ceramic depends on the specific application and desired properties. Factors like thermal conductivity, electrical insulation, and mechanical strength play a role in determining the best material for the job.

Staying informed about the advancements in ceramic 3D printing will allow you to leverage these durable, heat-resistant materials effectively, whether you’re developing cutting-edge electronics or creating beautiful, customized consumer goods.

Composites: Combining Strengths for Superior Performance

Composites are revolutionizing the field of 3D printing by combining two or more materials to create a product with enhanced properties. Picture the best attributes of individual materials merged into a single composite, delivering superior performance that’s hard to beat.

These materials blend fibers like carbon or glass with a polymer matrix, resulting in parts that are incredibly strong yet lightweight. Carbon fiber composites are particularly notable for their exceptional strength-to-weight ratio, making them ideal for applications where both robustness and weight reduction are critical.

The automotive and aerospace sectors are pioneers in adopting composite 3D printing. Cars and aircraft benefit significantly from components that are both lighter and stronger, directly contributing to improved performance and fuel efficiency. For example, Formula One teams use carbon fiber composites to create high-strength, lightweight parts that can withstand intense racing conditions.

Research and development in composite materials continuously push the boundaries of what’s possible. Innovations in resin systems and fiber reinforcements are leading to next-gen composites that are even more durable and versatile. These advancements are paving the way for new applications and efficiencies.

Effective use of composite 3D printing involves understanding the balance needed between the fiber and the matrix. The type of fiber, length, orientation, and quality of the polymer matrix all play a significant role in the final properties of the composite.

For anyone working with composites, staying current with the latest materials and methods is crucial. As new types of fibers and resins become available, they offer fresh opportunities to enhance performance and reduce costs. Leveraging the latest advancements ensures that you remain at the cutting edge of innovation, producing parts that meet the highest standards of strength and durability.

Eco-friendly Materials: Sustainability in 3D Printing

Eco-friendly materials have become a vital consideration in the evolution of 3D printing technologies. As industries across the globe confront the challenges of environmental sustainability, the drive to use materials that are kind to the planet becomes increasingly important.

Biodegradable and recycled materials have gained prominence. PLA, sourced from renewable resources like corn starch, is one such material widely used in 3D printing. It offers the benefits of reduced environmental impact without compromising on functionality. Similarly, recycled plastics offer a second life to materials that would otherwise contribute to waste, making them an excellent choice for sustainable projects.

Understanding the environmental impact of each material is crucial. For example, while some materials may be biodegradable, their production processes might not be as green as they seem. A holistic view that considers both the source and the manufacturing process ensures a genuinely eco-friendly approach.

Real-world applications of eco-friendly 3D printing materials are growing. From sustainable fashion accessories to biodegradable packaging solutions, these materials are finding their way into diverse fields. Schools and educational institutions are also adopting eco-friendly materials for teaching and projects, fostering an early appreciation for sustainability in young minds.

For those interested in incorporating eco-friendly materials into their 3D printing projects, staying informed about the latest sustainable options is key. Researching new materials, understanding their properties, and evaluating their environmental credentials will guide you in making responsible choices.

Integrating sustainable practices goes beyond material choices. Efficient design, minimizing waste, and optimizing printing processes all contribute to a more sustainable approach. By paying attention to the full lifecycle of a product, from material selection to disposal, you can significantly reduce your environmental footprint.

Committing to sustainability is beneficial not only for the planet but also for your brand’s image and consumer trust. Companies that prioritize eco-friendly practices often find that customers are more willing to support and invest in their products.

Future Trends and Innovations in Advanced 3D Printing Materials

Emerging materials and technologies in the realm of 3D printing are transforming the landscape, paving the way for innovations that promise to change the industry. From conductive polymers to shape-memory alloys, the future holds exciting possibilities.

Conductive polymers are at the forefront of this evolution, enabling 3D-printed electronics that merge functionality directly into the design. Imagine circuits, sensors, and even batteries seamlessly integrated into 3D-printed objects, reducing the need for separate components and enhancing efficiency. This can be a game-changer for the electronics industry, offering new avenues for design and application.

Shape-memory alloys, which can return to a predetermined shape when exposed to specific conditions, are another area of interest. These materials could lead to advancements in fields requiring adaptive components, like aerospace and robotics, where parts need to respond dynamically to changing conditions.

Nanomaterials are also making waves. Incorporating nanoparticles into 3D printing materials can significantly enhance properties such as strength, conductivity, and flexibility. Research in this niche is growing, and the potential applications are vast, from medical devices to high-performance sports equipment.

Looking ahead, industry experts predict the continued growth and diversification of 3D printing materials. Investment in research and development will drive unique solutions tailored to specific applications, making 3D printing more versatile and integrated across various fields.

Staying updated on these trends is crucial for anyone in the 3D printing sphere. Attending industry conferences, participating in webinars, and following cutting-edge research publications will help keep you informed. This proactive approach ensures you’re ready to capitalize on the latest advancements as they become available.

Investing in the future of 3D printing also means being open to adopting these new materials and technologies. Experimenting with different materials, collaborating with research institutions, and embracing innovation are key steps in staying ahead in a competitive market.

The convergence of materials science and 3D printing technology is set to redefine manufacturing. Embracing these future trends and innovations will be instrumental in driving forward-thinking solutions and maintaining a leading edge in this rapidly evolving field.

Unleash Your Creativity with COEX 3D Printing Filaments!

Are you ready to take your 3D printing projects to the next level? Introducing **COEX 3D Printing Filaments** – the ultimate choice for makers, designers, and innovators who demand the best in quality, versatility, and performance.

Why Choose COEX?

Our filaments are crafted in the USA using high-quality, eco-friendly materials to ensure your prints come out flawlessly every time. Whether you’re working on intricate designs, functional prototypes, or large-scale models, COEX filaments offer:

- Exceptional Precision: Achieve incredible detail and smooth finishes with our perfectly round, high-tolerance filaments.

- Wide Range of Materials: From PLA, ABS, and PETG to specialty blends like flexible TPU and high-strength Nylon, you’ve got the right filament for every project.

- Vibrant Color Selection: Stand out with our extensive palette of vivid, eye-catching colors that bring your creations to life.

- Eco-Conscious Production: Print with confidence, knowing COEX filaments are made from sustainably sourced materials and packaged in recyclable spools.

Limited-Time Offer!

For a limited time only, enjoy 20% off your first order with code COEX20 at checkout. Plus, every order over $50 ships FREE!

Don’t Miss Out! Stock up now and let your creativity flow with the unmatched quality of COEX 3D Printing Filaments. Your next masterpiece is just a print away.

—

Bullwinkle