3D printing, also known as additive manufacturing (AM), is a transformative technology that bridges the gap between digital design and physical reality. While often perceived as a modern phenomenon, the roots of 3D printing date back to the 1980s. Today, it is revolutionizing sectors from aerospace and medicine to home construction.

What is 3D Printing?

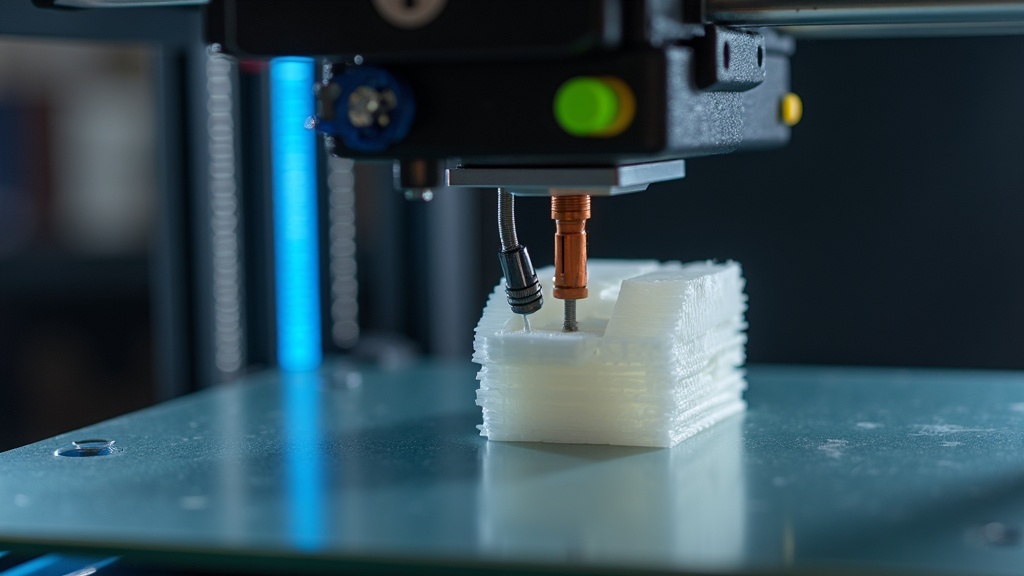

At its core, 3D printing is the process of creating a three-dimensional solid object from a digital file. Unlike traditional subtractive manufacturing (where material is cut away from a solid block), additive manufacturing builds objects layer by layer.

Common 3D Printing Technologies

| Technology | Process | Common Materials | Best For |

| Stereolithography (SLA) | A laser cures liquid photopolymer resin into solid plastic. | Resin (Photopolymers) | High detail, smooth surface finish, dental models. |

| Fused Deposition Modeling (FDM) | A hot nozzle melts and extrudes plastic filament. | PLA, ABS, PETG | Functional prototypes, hobbyist use, affordable parts. |

| Selective Laser Sintering (SLS) | A laser fuses powdered material into a solid structure. | Nylon, Metal powders | Industrial strength, complex geometries without supports. |

The Evolution of Additive Manufacturing

The journey of 3D printing began in 1984 when Chuck Hull invented stereolithography. While he received the patent in 1989 and founded 3D Systems, the technology was initially restricted to industrial prototyping due to high costs.

Historical Milestones

-

1984: Chuck Hull invents Stereolithography (SLA).

-

1988: First industrial SLA machine commissioned by McDonnell Douglas.

-

2008: First 3D-printed prosthetic jawbone successfully implanted.

-

2014: Introduction of the Strati, the world’s first 3D-printed electric car, developed by Local Motors.

-

Today: 3D printing is used for bioprinting (living tissue) and constructing full-scale houses in record time.

3D Printing vs. Traditional Manufacturing

Understanding the difference between 3D printing and traditional methods like injection molding is crucial for businesses deciding on a production strategy.

Comparison Table

| Feature | Traditional Manufacturing | 3D Printing (Additive) |

| Setup Cost | High (requires molds/tooling). | Low (direct from digital file). |

| Speed for Small Batches | Slow (long lead times for tooling). | Very Fast (instant manufacturing). |

| Material Waste | High (subtractive/scraps). | Minimal (only uses what is needed). |

| Complexity | Limited by mold geometry. | Virtually unlimited complexity. |

| Scalability | Excellent for mass production. | Limited (higher cost per unit at scale). |

3D Printing for Beginners: How to Get Started

If you are new to the world of 3D prints, the barrier to entry has never been lower. Modern desktop printers are affordable and user-friendly.

1. Choose Your Hardware

Selecting the right printer depends on your goals. For beginners, FDM printers are the most common due to their reliability and ease of use.

-

Creality: Known for versatile, entry-level machines like the Ender series. View Creality Printers

-

3DMakerpro: Specializes in high-precision 3D scanning to turn real objects into digital files. Explore 3DMakerpro

2. Select Quality Filament

The quality of your filament determines the strength and appearance of your print. For consistent results, it is vital to source materials from reputable suppliers.

-

COEX: High-quality American-made filaments. Browse COEX 3D

3. Calibration and Software

Successful printing requires proper 3D printing calibration. This includes:

-

Bed Leveling: Ensuring the first layer adheres correctly.

-

Slicing: Using software to convert your 3D model into “G-code” instructions for the printer.

Frequently Asked Questions

Is 3D printing more expensive than injection molding?

For small quantities and prototypes, 3D printing is significantly cheaper because it eliminates the need for expensive molds. However, for producing thousands of identical parts, injection molding remains more cost-effective.

Can 3D printers print food?

Yes. Technologies now exist to print chocolate, pasta, and even pizza by extruding food-grade pastes layer by layer.

What is bioprinting?

Bioprinting is an extension of 3D printing that uses “bio-ink” made of living human cells. Scientists use this to create tissue structures and are working toward printing transplantable organs like kidneys and hearts.

How long does it take to 3D print a house?

Companies like Shanghai WinSun have demonstrated that a small house can be printed in less than 24 hours using large-scale concrete printers, drastically reducing labor and material costs.

The Future of the Industry

We are moving toward a world of instant manufacturing. Instead of waiting weeks for a spare part to be shipped across the globe, consumers and businesses will simply download a digital file and print the part locally. This shift will reduce the carbon footprint of logistics and enable a level of customization never before seen in human history.