To fix under-extrusion without buying new parts, you must address the primary mechanical and software bottlenecks: clean the nozzle using the “cold pull” method, increase the extruder spring tension, ensure the PTFE tube is flush against the hotend, and calibrate your E-steps in the printer firmware. These adjustments ensure that the volume of plastic requested by your slicer matches the volume actually being deposited.

Disclosure: This post contains affiliate links to Creality, 3DMakerpro, and other partners. If you make a purchase through these links, I may earn a small commission at no extra cost to you. I also recommend COEX filament for high-performance projects via my partnership with them.

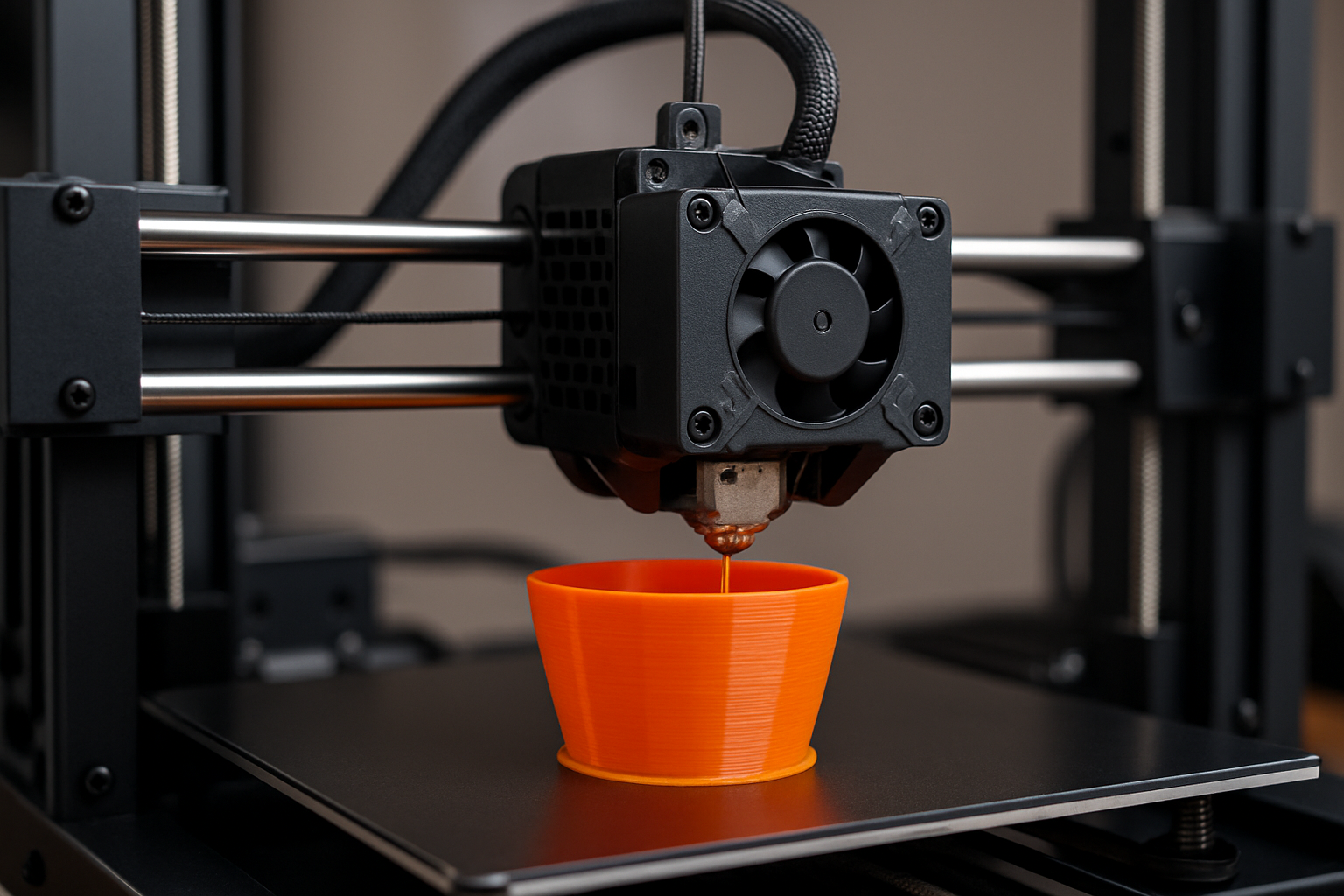

Understanding Under-Extrusion in FDM Printing

Under-extrusion occurs when your 3D printer fails to supply the amount of filament required for a solid, cohesive layer. While many guides suggest immediately replacing the extruder or nozzle, most issues are caused by friction, misalignment, or incorrect software values.

Before investing in new hardware from Creality or high-end scanners from 3DMakerpro, follow this systematic approach to restore your print quality.

Quick Troubleshooting Checklist

- Cold Pull: Remove internal clogs.

- Extruder Tension: Ensure the gear isn’t slipping.

- Bowden Gap: Eliminate the space between the tube and the nozzle.

- E-Step Calibration: Match firmware math to physical movement.

- Flow Rate: Adjust for material-specific variances.

1. The Cold Pull (Atomic Method)

A partial clog is the most common cause of under-extrusion. Tiny particles of charred filament or dust can restrict the nozzle orifice without completely blocking it.

How to perform it:

- Heat your hotend to the printing temperature of your current filament.

- Manually push filament through until it extrudes cleanly.

- Lower the temperature (to approximately 90°C for PLA or 140°C for PETG).

- Once the temperature is reached, quickly pull the filament out of the extruder.

- Inspect the tip; it should have the shape of the nozzle interior and be covered in dark residue. Repeat until the tip comes out clean.

2. Adjusting Extruder Spring Tension

If your extruder motor is spinning but the filament is sliding or being “chewed,” your tension is incorrect. Most stock printers, including entry-level Creality models, allow you to adjust the tension of the arm.

- The Fix: Tighten the tension screw on the extruder arm. This increases the grip of the drive gear on the filament.

- Caution: Do not overtighten, as this can flatten the filament, causing it to jam later in the PTFE tube.

3. Eliminating the Hotend Gap

In many printers, the PTFE (Bowden) tube must sit perfectly flush against the back of the nozzle. Even a 1mm gap creates a “dead zone” where molten plastic pools and degrades, causing massive resistance.

The “No-Cost” Fix:

- Heat the hotend and remove the nozzle.

- Inspect the end of your PTFE tube. If it is charred or uneven, use a sharp blade to make a perfectly square, 90-degree cut.

- Thread the nozzle back in, then back it off by one full turn.

- Push the PTFE tube down until it hits the nozzle.

- Tighten the nozzle the final turn while hot. This creates a mechanical “crush seal.”

4. Calibrating E-Steps (The Software Fix)

Your printer’s firmware uses a value called “Steps per mm” to determine how much the motor should turn to move 100mm of plastic. Often, factory settings are slightly off.

- Mark your filament 100mm and 120mm from the extruder entrance.

- Use your printer interface to “Extrude 100mm.”

- Measure how much filament remains. If 25mm remains instead of 20mm, you only extruded 95mm.

- Use the formula:

(Current E-Steps * 100) / Actual Extruded Amount = New E-Steps. - Update this value in your printer’s “Motion” or “Configuration” menu and save to EEPROM.

Maintenance vs. Upgrading

| Method | Cost | Effectiveness | Effort |

|---|---|---|---|

| Cold Pull | $0 | High (for clogs) | Low |

| E-Step Calibration | $0 | Permanent | Medium |

| PTFE Seating | $0 | Vital for Bowden | Medium |

| Buying New Hotend | $20+ | Total Reset | High |

Ready for Better Results?

If you have performed these steps and want to ensure your material quality isn’t the bottleneck, I highly recommend using COEX Filament. It is produced with industry-leading tolerances to prevent the very issues discussed here. Shop COEX Filament Here

Internal Links for Maintenance Mastery

To further optimize your setup, explore our other deep dives on 3D Printing Maintenance and Hardware Calibration. Consistent maintenance prevents the need for costly replacements from suppliers like HONG KONG CHAORONG CO., LIMITED.

Frequently Asked Questions

Does under-extrusion always mean a clog? No. It can be caused by low temperatures, high printing speeds, or a worn-out extruder gear. Always check your slicer settings before assuming a mechanical failure.

Can low-quality filament cause under-extrusion? Yes. Inconsistent filament diameter can cause the extruder to lose grip. Using premium brands like COEX minimizes this variable.

How often should I calibrate E-steps? You should calibrate E-steps once when you get the printer, and again if you change your extruder assembly or update your firmware.