Curious about 3D printing but not sure where to start? This beginner’s guide breaks it down with easy-to-understand insights, practical steps, and everything you need to kick off your desktop 3D printing journey.

The Magic of Making Things: Your First Step into 3D Printing

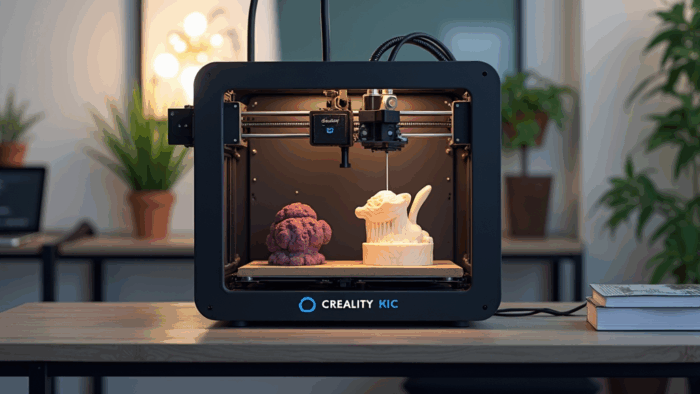

Imagine pressing a button and watching your ideas take shape—layer by layer, right before your eyes. That’s not science fiction anymore. It’s the wonder of desktop 3D printing. For curious beginners, creatives, and weekend tinkerers, this technology opens a portal into hands-on invention and self-expression. Whether you’re looking to make custom phone holders, cosplay props, or prototype your next big idea, desktop 3D printing makes it possible to transform imagination into something you can hold in your hands.

But here’s the catch: while the results can be magical, the learning curve can feel a bit intimidating. Filament types, bed leveling, slicing software—it’s a world with its own vocabulary and quirks. That’s why we’ve crafted this friendly, story-driven guide: to walk you through the essentials, step by step, and get you printing confidently in no time.

Why Desktop 3D Printing Is Worth Exploring

The beauty of desktop 3D printing lies in its accessibility. Once reserved for industrial use, these machines have found their way into schools, garages, and living rooms all over the world. They’ve gone from bulky, complex contraptions to sleek, user-friendly tools that anyone with a curious mind can master.

But it’s more than just a hobby—it’s a skillset. From STEM education to entrepreneurship, 3D printing is empowering people to create solutions tailored to their needs. Need a replacement part for a coffee grinder? Print it. Want a customized mount for your webcam? Design it. This ability to invent on-demand gives you an edge in creativity and problem-solving.

And for many, the real value lies in the joy of making—of turning idle ideas into tangible outcomes.

Choosing the Right Printer: FDM vs. Resin

If you’re brand new to 3D printing, your first big decision is choosing between the two most popular types of desktop printers:

FDM (Fused Deposition Modeling)

Think of FDM printers like hot glue guns on autopilot. They melt plastic filament and extrude it through a nozzle to build objects one layer at a time. These machines are generally more affordable, beginner-friendly, and perfect for larger prints.

Popular beginner FDM models include:

- Creality Ender 3 Series – A legendary budget-friendly workhorse.

- Bambu Lab A1 Mini – Fast, quiet, and easy to set up.

- Prusa MINI+ – Premium print quality with a plug-and-play experience.

Resin (SLA or MSLA)

Resin printers work very differently. They use light to cure liquid resin into solid layers. The result? Incredibly detailed prints—perfect for miniatures, jewelry, or intricate prototypes. The trade-off is a messier workflow and more post-processing steps.

Popular beginner resin models:

- Elegoo Mars 4 – Budget resin printing with quality results.

- Anycubic Photon Mono 2 – Great entry-level option with a decent build volume.

If you’re unsure, go FDM first. It’s easier, cheaper, and more forgiving while you’re learning the ropes.

| Feature | FDM Printers | Resin Printers (SLA/MSLA) |

|---|---|---|

| Printing Method | Melts plastic filament layer by layer | Uses UV light to cure liquid resin |

| Best For | Functional parts, prototyping, large prints | Miniatures, high-detail models, jewelry |

| Print Quality | Moderate detail (0.1–0.2mm layer height) | High detail (as fine as 0.025mm) |

| Ease of Use | Beginner-friendly setup and maintenance | Steeper learning curve, more cleanup |

| Material Cost | Lower (PLA, PETG, etc.) | Higher (UV-curable resin) |

| Post-Processing | Minimal (removing supports, sanding) | Requires washing and UV curing |

| Typical Print Size | Larger build volumes (up to 300mm+) | Smaller build volumes (100–150mm) |

| Environment | Safe for indoor use, minimal odor | Requires ventilation, resin is toxic |

Must-Have Tools and Materials for Your First Print

Your printer will likely come with the basics—but a few additional tools can make life much easier:

- Filament or Resin: PLA filament is ideal for beginners—easy to use and non-toxic. For resin, start with standard gray or white.

- Scraper/Spatula: Helps remove prints from the bed without damage.

- Digital Calipers: Essential for accurate measurements when designing your own models.

- Glue stick or PEI surface: Helps with print bed adhesion (especially for FDM).

- Isopropyl Alcohol & Nitrile Gloves: Must-haves for resin printing cleanup.

You’ll slowly build up your toolkit as you go, but these essentials will keep your first few prints on track.

Slicing Software: The Bridge Between Idea and Reality

Slicing software takes your 3D model and turns it into instructions your printer understands. This step is like giving your printer a recipe: what temperature to use, how fast to move, and how many layers to build.

Some beginner-friendly slicers include:

- Ultimaker Cura – Free, open-source, and widely supported.

- PrusaSlicer – Tailored to Prusa printers but useful for many machines.

- Bambu Studio – Designed for Bambu Lab printers but intuitive and feature-rich.

Most slicers let you preview your print layer by layer before hitting “Start,” giving you peace of mind before committing to a multi-hour job.

Where to Find 3D Models to Print

You don’t need to design your own objects from scratch (yet). There’s a massive ecosystem of downloadable 3D models available—many of them free.

Try these platforms:

- Thingiverse – A classic, with thousands of community-made designs.

- Printables – Curated, high-quality models with detailed print settings.

- Thangs – A smart search engine for 3D files.

- Cults3D & MyMiniFactory – Great for artistic and paid models.

Simply download the STL file, load it into your slicer, adjust your print settings, and you’re on your way.

How to Start 3D Printing at Home (Step-by-Step)

- Choose a Printer Type: Start with an FDM printer like the Ender 3 or Bambu Lab A1 Mini if you’re a beginner. Resin printers are great for high-detail prints but require more setup.

- Set Up the Printer: Unbox your printer and follow the included instructions. Level the bed (for FDM), and install any software or firmware updates.

- Download a 3D Model: Visit sites like Thingiverse, Printables, or Thangs to find your first STL file. Pick something simple, like a calibration cube or phone stand.

- Slice the Model: Use slicing software (Cura, PrusaSlicer, or Bambu Studio) to convert your STL into G-code, which tells the printer how to build the object.

- Insert Material: Load PLA filament (FDM) or pour resin into the vat (resin printer), depending on the type of printer you selected.

- Start the Print: Transfer the sliced file to your printer (via SD card, USB, or Wi-Fi), and press print. Monitor the first few layers to ensure proper adhesion.

- Post-Process Your Print: For FDM: remove supports and lightly sand if needed. For resin: wash with isopropyl alcohol and cure under UV light.

- Repeat and Improve: Learn from each print. Adjust settings, try new models, and gradually explore design software like TinkerCAD or Fusion 360.

Troubleshooting Your First Few Prints

Even the best printers need fine-tuning, and you’ll likely hit some snags early on. That’s part of the journey. Here are a few common beginner problems:

- First layer not sticking? Re-level your bed and clean the surface.

- Stringy prints? Lower your print temperature or tweak retraction settings.

- Uneven layers or blobs? Check your nozzle, filament feed, or belt tension.

When in doubt, YouTube and Reddit are packed with helpful communities ready to guide you. Don’t be afraid to ask questions or experiment.

Safety and Best Practices

While 3D printing is generally safe, a few precautions go a long way:

- Ventilation: Print in a well-ventilated area, especially when using resin.

- Supervision: Don’t leave your printer running unattended, especially overnight.

- Fire Safety: Invest in a smoke detector and a small fire extinguisher near your setup.

As with any creative tool, knowledge is your best defense—and your best asset.

Growing Your Skills: From Downloading to Designing

Once you’ve mastered printing others’ designs, you may find yourself itching to create your own. That’s when the real magic begins.

Learning to design 3D models can feel like learning a new language—but it’s deeply rewarding. Beginner-friendly CAD software like TinkerCAD and Fusion 360 makes it easier than ever to dip your toes into design.

Before long, you’ll be building models that solve real problems in your home, your work, or your hobbies.

Embrace the Journey

Starting your 3D printing journey isn’t just about pressing “Print.” It’s about curiosity, patience, and the satisfaction that comes from learning something new. Each print—flawed or flawless—is a step forward. Each challenge overcome is a layer of progress.

You don’t have to be an engineer or artist to enjoy 3D printing. You just need to be someone who believes that making something yourself is worth it.

So plug in that printer, load your first model, and watch your world expand—layer by incredible layer.

https://store.creality.com/