So, you’ve heard about 3D printing and are curious about how it all works. Maybe you’ve seen someone create intricate figurines, custom phone cases, or even practical household gadgets and thought, Could I do that too? The answer is an enthusiastic yes! But like any new hobby, diving into 3D printing might feel a bit overwhelming at first. Fear not—this guide will walk you through the basics, breaking things down into digestible steps so you can start your creative journey with confidence.

What is 3D Printing?

At its core, 3D printing is a technology that turns digital designs into physical objects. Think of it as building something layer by layer—like stacking pancakes, only instead of batter, you’re working with materials such as plastic, resin, or even metal. A 3D printer reads a digital file, typically in STL format, and meticulously creates an object, one precise layer at a time.

This process, known as additive manufacturing, has revolutionized how we think about creating things. While it might sound like something out of science fiction, 3D printing is surprisingly approachable. It’s no longer limited to industrial applications; hobbyists around the world are using it to make everything from personalized gifts to functional tools.

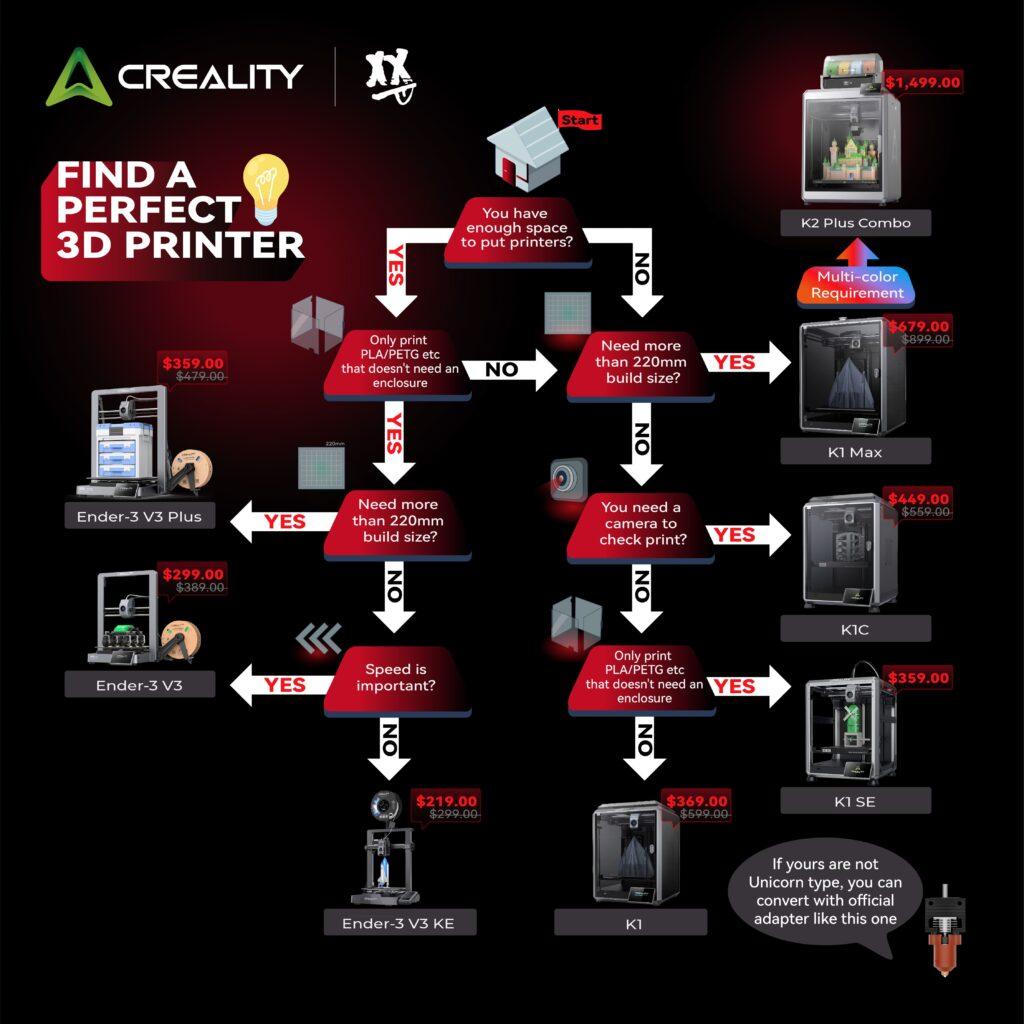

Choosing the Right Printer

The first step in your 3D printing adventure is choosing the printer that best fits your needs. While there are many types of printers out there, two stand out as the most popular for beginners: FDM and SLA printers.

FDM, or fused deposition modeling, is the most accessible option. These printers work by melting a plastic filament and layering it to form your design. They are versatile, affordable, and perfect for larger projects. However, the final product might require a bit of post-print sanding if you want a smooth surface.

If you’re more interested in high-detail prints with smooth finishes, an SLA printer might be the better choice. Instead of plastic filament, these printers use a liquid resin that is hardened layer by layer with a laser. This process results in beautifully detailed models but requires a little more effort, as working with resin can be messy and involves additional steps to clean and cure the prints.

For those new to the world of 3D printing, starting with an FDM printer is often the best choice. It’s easy to set up, has a lower learning curve, and is supported by a vibrant community of enthusiasts who are happy to share their experiences and tips.

The Essential Tools and Materials

Once you’ve chosen your printer, you’ll need a few additional tools and materials to get started. For FDM printing, the primary material is the filament. PLA, or polylactic acid, is the most beginner-friendly filament because it’s easy to work with and available in a rainbow of colors. It’s also biodegradable, making it an eco-conscious choice for hobbyists.

To ensure your prints adhere properly to the printer’s build plate, you might need tools like painter’s tape or a glue stick. These simple items can make a big difference in the quality of your prints, preventing issues like warping or lifting during the printing process.

You’ll also want some basic post-print tools, such as a scraper for removing prints from the build plate and a pair of pliers or clippers for trimming excess filament. As you gain more experience, you might find yourself reaching for sandpaper, hobby knives, or even a 3D pen for repairs and enhancements.

Taking Your First Steps

Now that your printer is set up and your tools are ready, it’s time to take your first steps into the world of 3D printing. The best way to start is by selecting a simple project—something that’s easy to print but still satisfying to complete. Many beginners start with pre-made designs from websites like Thingiverse, where you’ll find thousands of free, beginner-friendly models to choose from.

Once you’ve selected a design, load it into your printer’s software, known as a slicer. This program prepares your digital file for printing, allowing you to customize settings like layer height, print speed, and material type. While these settings might seem daunting at first, most printers come with presets to guide you.

When your first print finishes, there’s a good chance it won’t be perfect—and that’s okay! Every mistake is a learning opportunity, and with practice, you’ll develop the skills to troubleshoot and refine your process. As you grow more confident, you can experiment with more complex projects and even design your own models.

Embrace the Journey

3D printing is more than just a hobby—it’s a gateway to endless creativity and problem-solving. Whether you’re crafting unique gifts, repairing household items, or simply exploring the possibilities of this exciting technology, every print is an opportunity to learn and grow.

So, set up your printer, gather your tools, and start small. Before you know it, you’ll be holding your first 3D-printed creation, feeling that magical blend of pride and curiosity that keeps makers coming back for more. Welcome to the world of 3D printing—you’re going to love it here.

Exploring Different Filament Types for Hobbyist 3D Printers

When it comes to 3D printing, the filament you choose plays a significant role in shaping the success and quality of your creations. With numerous options available, each offering unique properties, the task of selecting the right one can be both exciting and overwhelming. This guide explores some of the most popular filaments, dives into the world of specialty materials, and provides practical advice to help you make informed decisions about filament selection, storage, and handling.

The Classics: PLA, ABS, PETG, and TPU

For most hobbyist 3D printers, a handful of filament types dominate the field, each with its own strengths and ideal applications. PLA, or polylactic acid, is a staple for beginners and experts alike. Derived from renewable resources such as cornstarch and sugarcane, PLA is an eco-friendly filament that is both easy to use and widely accessible. Its low melting point and forgiving nature make it ideal for first-time users, while its glossy finish and vibrant colors ensure aesthetically pleasing results. However, PLA’s lower heat resistance and brittleness mean it’s best suited for decorative objects or prototypes that won’t endure heavy wear and tear.

In contrast, ABS, or acrylonitrile butadiene styrene, offers enhanced durability and heat resistance, making it an excellent choice for functional projects like tool handles or automotive parts. Its robustness comes with a few challenges, including a tendency to warp during printing and a noticeable odor that requires good ventilation. These factors make ABS better suited for intermediate users who have access to a heated print bed and an enclosed printing area.

PETG, a blend of polyethylene terephthalate and glycol, serves as a middle ground between PLA and ABS. It combines the ease of use found in PLA with the strength and flexibility of ABS, creating a material that is highly durable and resistant to moisture and chemicals. This versatility makes PETG a favorite for practical projects such as food-safe containers or outdoor equipment. Although it may require some fine-tuning during the printing process, PETG’s reliability and broad applications make it an invaluable filament for hobbyists looking to expand their skills.

For prints requiring elasticity and resilience, TPU, or thermoplastic polyurethane, is an outstanding option. Its flexible properties make it ideal for projects like phone cases, gaskets, or even wearable accessories. TPU, however, demands a more cautious approach due to its tendency to bend and stretch during printing. Slower print speeds and meticulous calibration are often necessary to achieve optimal results, making TPU a rewarding but challenging material for adventurous makers.

Specialty Filaments for Creative Projects

Beyond the basics, specialty filaments open up new creative possibilities, allowing hobbyists to experiment with unique textures, appearances, and functions. For instance, wood-filled filaments combine PLA with wood fibers, resulting in prints that mimic the appearance and feel of real wood. These prints can be sanded, stained, or varnished, making them an excellent choice for crafting rustic or natural-looking objects.

Metal-filled filaments introduce powdered metals like copper, bronze, or aluminum into the mix, lending a weighty, metallic aesthetic to prints. These materials are ideal for jewelry, sculptures, or other decorative projects that benefit from a realistic metallic finish. However, their abrasive nature can wear down standard nozzles over time, so a hardened nozzle is often recommended.

For those who enjoy a touch of whimsy, glow-in-the-dark filaments are a fun option. Made by blending phosphorescent materials with PLA, these filaments create prints that emit a soft glow in the dark after being exposed to light. They’re perfect for toys, themed decorations, or safety markers. Similarly, carbon fiber-filled filaments offer an entirely different advantage: strength and lightness. Infused with carbon fibers, these materials are ideal for creating durable, lightweight parts such as drone frames or mechanical components.

Silk PLA is another specialty filament that caters to aesthetics, producing prints with a shiny, smooth finish reminiscent of silk fabric. This filament is particularly popular for decorative items where visual appeal is a priority.

Tips for Choosing the Right Filament

Selecting the appropriate filament for your project involves balancing several factors, such as the purpose of the print, your printer’s capabilities, and your level of expertise. For purely decorative objects, PLA or silk PLA is often the best choice, as these materials are easy to use and produce striking results. Functional or outdoor projects, on the other hand, may require the durability of PETG or the flexibility of TPU.

It’s also important to consider your printer’s specifications. Not all printers can handle every filament type, especially those requiring higher temperatures or specific nozzle materials. Reviewing your printer’s manual and experimenting with beginner-friendly filaments like PLA can help you gain confidence before tackling more complex materials.

Best Practices for Storing and Handling Filaments

Proper storage and handling of filaments are essential to maintain their quality and ensure consistent printing results. Many filaments, particularly PLA and PETG, are hygroscopic, meaning they absorb moisture from the air. This moisture can cause poor print quality, including bubbling, stringing, or weak layers. To prevent these issues, filaments should be stored in a cool, dry environment.

Airtight containers or vacuum-sealed bags with desiccant packets are excellent options for keeping filaments dry. If a filament has absorbed moisture, it can often be salvaged by drying it in a filament dryer or a low-temperature oven. Regularly inspecting your filaments for signs of brittleness or discoloration can also help you address issues before they impact your prints.

Embracing the Possibilities

Exploring the wide variety of 3D printing filaments is an exciting journey that allows hobbyists to tailor their creations to specific needs and preferences. From the simplicity of PLA to the innovation of metal-filled or glow-in-the-dark options, each material offers unique opportunities for creativity and functionality. By understanding the properties of different filaments, choosing the right material for each project, and following best practices for storage and handling, you’ll set yourself up for success in every print. Whether you’re crafting intricate sculptures or durable tools, the possibilities are as limitless as your imagination.

Creative 3D Printing Projects for Hobbyists

3D printing isn’t just a tool—it’s a gateway to a world of boundless creativity. With your printer and some imagination, you can transform simple ideas into tangible, functional, and artistic creations. From practical household items to quirky decorative pieces, the possibilities are endless. Whether you’re a seasoned maker or a beginner just diving into this exciting hobby, here’s a guide to unique project ideas, step-by-step instructions for popular prints, and tips for adding your personal flair to every creation.

Unique and Fun Project Ideas

The beauty of 3D printing lies in its versatility. You can design objects that solve everyday problems, add charm to your living space, or simply make you smile. For household items, consider printing cable organizers, custom hooks, or storage solutions that perfectly fit your drawers or shelves. These functional prints not only make life easier but also give you the satisfaction of creating something truly useful.

On the decorative side, 3D printing allows for intricate designs that would be difficult to craft by hand. Try creating unique planters shaped like animals or geometric patterns to brighten up your home. Personalized coasters, picture frames, or jewelry stands also make great gifts for loved ones. If you’re looking for something playful, experiment with 3D-printed toys, board game accessories, or even quirky keychains.

For those with a passion for storytelling, consider designing figurines, miniatures, or dioramas. Many hobbyists use 3D printing to bring fictional characters or imaginative worlds to life, combining artistry with technical skill.

Step-by-Step Guides for Popular Projects

Let’s take a closer look at a few popular projects and how to approach them. One beginner-friendly idea is a custom phone stand. Start by downloading or designing a simple STL file that matches your phone’s dimensions and preferred angle. Use your slicer software to set a standard layer height, typically 0.2mm, and choose PLA filament for an easy print. Once the print is complete, you can sand any rough edges and even paint it for a personalized touch.

Another fun project is a succulent planter. Many online repositories offer free designs for small planters in creative shapes, such as animals, geometric forms, or even retro gaming icons. After printing, consider applying a coat of sealant to make the planter waterproof. You can then fill it with soil and add a succulent to create a charming, custom piece of greenery.

If you’re up for a challenge, try crafting a mechanical model like a gear-based puzzle or a working clock. These projects require precise calibration and assembly, but they’re incredibly rewarding once complete. Plus, they’re great conversation starters and demonstrate the functional potential of 3D printing.

Inspirational Stories from the 3D Printing Community

The 3D printing community is filled with makers who have pushed the boundaries of creativity and innovation. For instance, some hobbyists have used their printers to create assistive devices like prosthetic hands or custom grips for tools, making life easier for people with physical challenges. Others have focused on sustainable printing by recycling materials to produce eco-friendly designs.

One inspiring story comes from a maker who printed a fully functional electric violin, combining their love for music and technology. Another hobbyist turned their passion for tabletop gaming into a small business by designing and printing detailed miniatures and terrain pieces. These stories remind us that 3D printing is not just about creating objects—it’s about turning ideas into reality and sharing them with others.

Tips for Adding Personal Touches to Your Prints

While downloading ready-made designs is a great way to get started, adding personal touches to your prints can make them uniquely yours. Customization begins in the design phase, where you can modify existing models or create your own using free CAD software like Tinkercad. For example, you can add names, initials, or meaningful symbols to everyday objects, turning them into personalized gifts.

Painting and finishing techniques also play a big role in customization. Acrylic paints, metallic finishes, or even hydro-dipping can transform a basic print into something extraordinary. If you’re working with wood or metal-filled filaments, sanding and staining can bring out a realistic texture that enhances the final product.

Another creative option is to experiment with multi-color printing or filament changes during the print. Some printers support dual extrusion, allowing you to combine colors or materials for a striking effect. For single-extruder setups, manually swapping filament mid-print can achieve a similar result.

Embrace the Joy of Creation

3D printing offers hobbyists a unique opportunity to explore their creativity and solve practical problems in innovative ways. Whether you’re crafting functional household items, designing intricate decorative pieces, or tackling ambitious mechanical models, the process is as rewarding as the final product. Draw inspiration from the community, try new techniques, and don’t be afraid to experiment. Every print is a step forward in your creative journey, and the only limit is your imagination. So, fire up your printer, grab some filament, and start making something amazing today!

Enhancing Print Quality: Troubleshooting Common Issues

When it comes to 3D printing, even the most seasoned hobbyists occasionally encounter problems that impact print quality. Issues like warping, stringing, and layer shifting can be frustrating, but the good news is that most problems have straightforward solutions. With a bit of troubleshooting, fine-tuning, and advanced techniques, you can achieve consistently excellent results. Let’s explore the most common challenges, their solutions, and best practices for creating high-quality prints.

Tackling Common Printing Problems

One of the most frequently encountered issues in 3D printing is warping. Warping occurs when the edges of a print curl upwards, detaching from the build plate and distorting the model. This typically happens because the cooling filament shrinks unevenly, creating tension that pulls the edges off the bed. Warping is particularly common with filaments like ABS, which are prone to temperature fluctuations. To combat warping, ensure that your build plate is heated to the recommended temperature for your filament and consider using adhesion aids such as painter’s tape, glue stick, or a specialized printing surface like PEI sheets. Enclosing your printer can also help by maintaining a stable printing temperature.

Another common issue is stringing, which manifests as thin, unwanted threads of filament between parts of your print. Stringing occurs when filament oozes out of the nozzle while the printer is moving between sections. To reduce stringing, adjust your retraction settings in your slicer software. Retraction pulls filament back into the nozzle during non-printing moves, preventing oozing. Additionally, ensure that your print temperature isn’t too high, as excessive heat can cause the filament to flow too freely.

Layer shifting is a more dramatic issue, where successive layers are misaligned, creating a jagged or distorted model. This problem often stems from mechanical issues such as loose belts, misaligned pulleys, or obstructions on the printer’s rails. Check your printer’s belts and ensure they are properly tensioned, inspect for debris or blockages on the rails, and verify that the printer’s frame is securely assembled. Regular maintenance is key to preventing these mechanical problems.

Solutions and Tips for Improving Print Quality

Achieving high-quality prints starts with proper setup and attention to detail. Bed leveling is one of the most critical factors. An uneven bed can cause poor adhesion, leading to warped or failed prints. Manually level your bed by adjusting the screws at each corner or use an auto-leveling sensor if your printer supports it. To ensure accuracy, use a sheet of paper to test the nozzle’s distance from the bed—it should just barely drag across the surface without tearing.

Temperature settings are equally important. Each filament type has an optimal range for both the nozzle and the bed. Printing too hot can lead to stringing and blobby details, while printing too cold can cause poor layer adhesion and brittle prints. Experiment with your filament at different temperatures and create a temperature tower—a model designed to test print quality at various temperatures—to find the sweet spot.

Calibration is another essential step in improving print quality. Begin by calibrating your printer’s extruder to ensure it is extruding the correct amount of filament. Over-extrusion can lead to messy prints, while under-extrusion can weaken your model. Many slicer programs include test models for extrusion calibration, or you can manually measure and adjust the extrusion multiplier.

Advanced Techniques for High-Quality Prints

Once you’ve mastered the basics, advanced techniques can take your prints to the next level. For example, fine-tuning layer height can significantly impact print quality. A smaller layer height results in smoother surfaces and better detail but increases print time. Use a balance that suits your project—lower layer heights for intricate models and higher ones for functional parts.

Another technique is optimizing print speed. Slower speeds often yield better results, especially for detailed or small models. Fast printing can introduce artifacts like ghosting or vibrations, so adjust your slicer settings to match your printer’s capabilities and the complexity of your design.

Experimenting with supports and overhangs is also essential for improving challenging prints. Supports provide a temporary structure for overhanging sections, but they can leave marks on the finished piece. Using custom supports in your slicer or testing with tree-style supports can minimize contact points and make removal easier.

For hobbyists seeking exceptional surface quality, post-processing can make a world of difference. Sanding and painting PLA prints can smooth out imperfections, while acetone vapor polishing can create a glossy finish on ABS models. Additionally, using a hardened steel nozzle allows you to print with abrasive filaments, such as those filled with carbon fiber or metal, to achieve unique finishes and properties.

Embracing the Process

Improving print quality is a journey of trial and error, but each successful adjustment brings you closer to mastery. By addressing common issues like warping, stringing, and layer shifting, fine-tuning your printer’s settings, and exploring advanced techniques, you’ll gain the skills to tackle increasingly complex projects. Remember, even the most experienced 3D printing enthusiasts started with imperfect prints. Embrace the process, experiment with new methods, and let each print bring you one step closer to perfection.

Customizing Your 3D Printer

When it comes to 3D printing, customization doesn’t stop at the models you create—your printer itself can be tailored to suit your needs. From simple DIY tweaks to advanced upgrades, enhancing your printer’s performance can lead to better print quality, increased reliability, and a more enjoyable experience. In this guide, we’ll explore popular modifications, share tips for DIY enhancements, and highlight success stories from the community.

Upgrades and Modifications to Enhance Performance

Enhancing your printer’s performance often starts with a few key upgrades. One of the most popular is upgrading the hotend or nozzle. Stock nozzles are sufficient for basic materials like PLA, but switching to a hardened steel nozzle can allow you to print abrasive filaments such as carbon fiber or metal-infused materials without damaging your equipment. For improved temperature control, consider upgrading to an all-metal hotend, which can handle higher temperatures and expand your filament options.

Another impactful upgrade is adding a dual-gear extruder. Standard single-gear extruders can struggle with flexible filaments like TPU or maintaining consistent filament flow. A dual-gear extruder grips the filament more securely, reducing jams and ensuring smoother extrusion.

For many hobbyists, the next step is improving build plate adhesion. Swapping your stock build plate for a glass or PEI sheet can create a more consistent printing surface, reducing warping and improving first-layer quality. Some upgrades, like magnetic flex plates, also make removing finished prints easier, preventing damage to both the model and the printer.

DIY Modifications for Better Print Quality

Customizing your printer doesn’t always require buying new components—many improvements can be achieved with simple DIY modifications. For instance, adding dampers to your printer’s stepper motors can significantly reduce noise and vibrations, leading to quieter operation and smoother prints. These dampers can often be 3D-printed themselves or purchased affordably online.

Another common DIY mod is creating or downloading custom cable management solutions. Loose cables can cause tangles, interfere with the movement of your printer, and even create safety hazards. By printing clips, chains, or guides, you can organize your cables and improve the overall efficiency of your setup.

Improving cooling is another easy DIY enhancement. Stock fans may not provide optimal airflow, leading to issues with stringing or poor layer adhesion. Upgrading or repositioning your cooling fans can address these issues, and many designs for improved fan ducts are available online. Simply printing a new duct tailored to your model can enhance airflow and boost print quality.

Adding Features for Convenience and Versatility

If you’re ready to take your printer to the next level, consider adding advanced features like auto-bed leveling. Manually leveling your printer’s bed can be a time-consuming and frustrating process. Installing an auto-bed leveling sensor, such as a BLTouch or inductive probe, automates this task, ensuring your bed is perfectly calibrated for every print. Many popular printers, like the Ender 3, have detailed guides for integrating these sensors.

Another transformative addition is building an enclosure. Enclosures maintain a stable printing environment by protecting your printer from drafts and temperature fluctuations. This is particularly beneficial for filaments like ABS, which require consistent heat to prevent warping. Enclosures also reduce noise and contain potentially harmful fumes from certain materials. Whether you purchase a pre-made enclosure or build your own from plexiglass and printed connectors, this upgrade is a game-changer for achieving professional-quality results.

For those seeking convenience, adding a filament runout sensor or a webcam for remote monitoring can save time and prevent failed prints. These modifications are especially useful for long prints, allowing you to step away from your printer without worrying about interruptions.

Success Stories and Examples of Custom Mods

The 3D printing community is filled with inspiring examples of how customization can elevate a printer’s performance. For instance, one user transformed their budget Ender 3 into a near-professional machine by adding upgrades like a direct drive extruder, linear rail guides for improved precision, and a custom-built enclosure. This overhaul allowed them to successfully print high-quality parts for robotics projects that rivaled those made by far more expensive machines.

Another enthusiast shared their success in printing flexible materials by switching to a dual-gear extruder and upgrading the printer’s cooling system. Before these mods, their attempts at flexible prints were plagued with jams and inconsistent layers. After the changes, they produced flawless phone cases and wearable accessories with ease.

One particularly innovative maker created a heated chamber for their printer, improving results with high-temperature filaments like nylon and polycarbonate. Using a combination of a homemade enclosure and an external heater, they achieved warping-free prints that met industrial standards.

Resources and Links for Further Exploration

If you’re ready to dive into customizing your printer, these resources can guide you through the process:

- Thingiverse: A vast library of free 3D-printable designs, including upgrades like fan ducts and cable management solutions.

- Prusa Knowledge Base: Detailed guides on upgrades, modifications, and troubleshooting for Prusa printers (many concepts apply to other models too).

- Teaching Tech YouTube Channel: Comprehensive tutorials on printer upgrades, mods, and calibration techniques.

- 3D Printing Wiki: An open-source knowledge base covering a wide range of topics, from beginner tips to advanced mods.

- OctoPrint: A platform for remote monitoring and control of your 3D printer, with instructions for adding webcams and other enhancements.

Unlocking Your Printer’s Potential

Customizing your 3D printer is more than just improving performance—it’s about personalizing your setup to match your unique needs and interests. From simple DIY modifications to advanced upgrades, these enhancements can transform your machine into a powerhouse of creativity and precision. Whether you’re reducing noise, improving print quality, or adding features like auto-bed leveling, each step brings you closer to realizing the full potential of your 3D printer. Dive in, experiment, and enjoy the process of making your printer truly yours!

Adventurer 5M Pro

Eco-Friendly 3D Printing: Sustainable Practices for Hobbyists

3D printing offers endless creative possibilities, but like any technology, it comes with environmental considerations. Fortunately, hobbyists can adopt eco-friendly practices to make their 3D printing greener and more sustainable. From choosing biodegradable filaments to reducing waste, every step toward sustainability not only benefits the planet but also helps foster a responsible approach to this exciting technology. Let’s explore how you can embrace eco-friendly 3D printing practices.

Using Recyclable and Biodegradable Filaments

One of the simplest ways to make your 3D printing more eco-friendly is by choosing the right filament. PLA (polylactic acid) is one of the most sustainable options available. Derived from renewable resources like cornstarch or sugarcane, PLA is biodegradable under industrial composting conditions. It’s also easy to print with, making it an ideal choice for beginners and seasoned hobbyists alike.

Recyclable filaments, such as PETG, are another excellent option. While PETG isn’t biodegradable, it is recyclable and offers durability and flexibility. Many manufacturers are now creating filaments from recycled plastic, giving materials a second life instead of sending them to landfills. Some even offer filament made from ocean plastics or other waste sources, combining functionality with environmental impact reduction.

For those interested in experimenting with specialty materials, there are even wood-filled filaments, which combine PLA with wood fibers to create a biodegradable material that mimics the look and feel of real wood. These options allow you to expand your creative horizons while staying eco-conscious.

Tips for Reducing Waste and Reusing Materials

Waste is a common byproduct of 3D printing, from failed prints to support structures. However, with a little planning, you can significantly reduce the amount of material that ends up in the trash. One key strategy is to carefully calibrate your printer to minimize errors. Proper bed leveling, temperature settings, and extrusion calibration can prevent many failed prints before they happen.

Reusing materials is another effective way to reduce waste. Many hobbyists use filament recyclers to process failed prints and leftover scraps into new spools of filament. While these machines require an initial investment, they can save money in the long run and drastically cut down on waste.

In addition to reusing filament, consider repurposing failed prints or scraps for other projects. Small pieces can be used for testing new printer settings or as functional parts in DIY projects. You can also save excess material for repairing prints or experimenting with creative designs.

Eco-Friendly Project Ideas and Sustainable Printing Practices

Sustainable 3D printing isn’t just about materials—it’s also about the projects you choose. For instance, consider designing and printing reusable household items like planters, storage containers, or custom organizers. These practical prints can replace single-use plastics or cheaply made items that might otherwise end up in a landfill.

Another idea is to create products that support sustainable living. For example, you could print gardening tools, seed planters, or rainwater collection accessories. You might also explore designs for repair parts to extend the life of broken items, reducing the need to buy new replacements.

In your daily printing practices, try to use only the filament you need. Optimize designs to minimize the use of support structures, which often generate waste. Many slicer programs include options for tree-style supports or other settings that reduce material usage while still providing adequate support during the print.

Impact of Sustainable 3D Printing on the Environment

Sustainable 3D printing has the potential to significantly reduce the environmental impact of manufacturing. By adopting eco-friendly practices, hobbyists can help reduce waste, conserve resources, and minimize the carbon footprint of their projects. For example, using biodegradable or recyclable materials instead of petroleum-based plastics reduces reliance on fossil fuels and decreases the amount of non-degradable waste.

Moreover, 3D printing itself offers a more sustainable manufacturing alternative by using only the material needed to create an object, unlike traditional subtractive methods that generate large amounts of scrap. When combined with renewable materials and waste reduction strategies, 3D printing becomes a powerful tool for sustainable innovation.

As more hobbyists and manufacturers embrace eco-friendly practices, the cumulative effect on the environment could be profound. By incorporating sustainable methods into your 3D printing routine, you’re contributing to a growing movement that prioritizes creativity and responsibility in equal measure.

The Path to Greener Printing

Eco-friendly 3D printing is about making thoughtful choices at every stage of the process. From selecting biodegradable or recyclable materials to optimizing your prints for minimal waste, these practices empower hobbyists to create responsibly. By designing projects that support sustainable living and exploring ways to reuse and recycle materials, you can turn your 3D printer into a force for environmental good. Small steps lead to significant changes, and every sustainable choice brings us closer to a greener future—one layer at a time.

The Future of 3D Printing: Trends and Innovations for Hobbyists

3D printing has come a long way since its inception, and the pace of innovation shows no signs of slowing down. For hobbyists, the future holds exciting possibilities, from advanced technologies to new materials that redefine what’s possible. Let’s explore the latest advancements, emerging materials, the influence of AI and IoT, and predictions for the hobbyist 3D printing community.

Latest Advancements in 3D Printing Technology

The technology behind 3D printing is evolving rapidly, bringing tools and capabilities once reserved for industrial settings into the hands of hobbyists. One of the most transformative advancements is the rise of high-speed printing. Printers like the Bambu Lab X1 Carbon and Prusa XL are pushing the boundaries of speed and efficiency, making it easier for hobbyists to tackle large projects or batch production. These machines combine precision with speed, enabling faster iterations and reducing waiting times.

Another significant trend is the growing accessibility of multi-material and multi-color printing. Dual-extrusion systems and filament-switching technologies allow users to create complex, colorful prints in a single run. This capability is particularly exciting for artists, designers, and anyone looking to add vibrant details to their creations.

Innovations in resin printing are also noteworthy. Hobbyists now have access to affordable SLA and DLP printers capable of producing incredibly detailed models. Advancements in resin formulations and curing methods make these printers more user-friendly and environmentally sustainable.

For more information on emerging printer technologies, visit All3DP.

Emerging Materials and Their Potential Uses

The range of materials available to hobbyists is expanding, opening new doors for creativity and functionality. Conductive filaments, for example, allow users to print circuits directly into objects, creating functional electronics like touch sensors and LED integrations.

Other materials, such as biodegradable and plant-based composites, are gaining popularity for their eco-friendly properties. These filaments combine PLA with organic additives like algae, hemp, or cork, offering unique textures and sustainable options for hobbyists concerned about the environment.

High-performance materials like PEEK and PEI (often branded as Ultem) are also becoming more accessible. These filaments, once used exclusively in industrial applications, are incredibly strong, heat-resistant, and durable. While they require advanced printers with high-temperature capabilities, they’re ideal for projects that demand exceptional strength, such as drone parts or custom mechanical components.

Metal-infused filaments and flexible materials like TPU continue to evolve, providing hobbyists with new ways to experiment and innovate.

For a deeper dive into materials, check out MatterHackers’ filament guide.

How AI and IoT Are Influencing Hobbyist 3D Printing

Artificial intelligence (AI) and the Internet of Things (IoT) are revolutionizing how hobbyists approach 3D printing. AI-powered slicers are becoming increasingly sophisticated, using machine learning to optimize print settings for specific models and materials. This not only improves print quality but also simplifies the process for beginners.

IoT integration allows for remote monitoring and control of 3D printers via smartphones or web apps. Platforms like OctoPrint and Creality Cloud enable users to start, stop, and supervise prints from anywhere, providing convenience and peace of mind. Combined with AI, these systems can detect errors in real-time, such as filament jams or layer shifts, and notify users before a print fails.

In the future, we may see fully autonomous printers that use AI to self-calibrate, select optimal settings, and even suggest design improvements. Such advancements will make 3D printing more accessible and efficient than ever before.

Learn more about AI-driven tools for 3D printing at Prusa Research.

Predictions for the Future of 3D Printing in the Hobbyist Community

As technology continues to advance, the hobbyist 3D printing community is poised for significant growth and transformation. Accessibility will remain a driving force, with more affordable, feature-rich printers entering the market. The democratization of high-end capabilities, like multi-material printing and AI-driven tools, will empower hobbyists to push their creative boundaries.

The rise of sustainability in 3D printing will also play a key role. With increasing awareness of environmental issues, hobbyists are likely to embrace recycled filaments, biodegradable materials, and energy-efficient practices. This trend will not only benefit the planet but also inspire innovative projects centered around sustainability.

Collaborative platforms will continue to strengthen the community. Websites like Thingiverse, MyMiniFactory, and Cults will evolve, incorporating AI-powered search and customization features to help hobbyists find and adapt designs with ease.

Finally, the integration of 3D printing with other technologies, such as robotics, electronics, and virtual reality, will create entirely new possibilities. Imagine designing a model in VR, printing it on a high-speed multi-material printer, and integrating it into a robotic project—all from the comfort of your home.

For ongoing trends and forecasts, follow 3D Printing Industry.

The Road Ahead

The future of 3D printing is bright, and hobbyists are at the forefront of this exciting journey. As printers become faster, smarter, and more versatile, and as new materials continue to expand what’s possible, the potential for creativity and innovation grows exponentially. Whether you’re a beginner or a seasoned maker, embracing these trends will ensure you stay ahead of the curve and fully enjoy the incredible world of 3D printing. Let your imagination guide you—the possibilities are truly endless!

Building a Home Workshop for 3D Printing

Creating a dedicated home workshop for 3D printing is a rewarding way to enhance your hobby. A well-organized, functional space improves efficiency, ensures safety, and makes the entire printing process more enjoyable. Whether you’re printing intricate models or functional parts, this guide covers the essentials for setting up your workspace, gathering tools and accessories, staying safe, and maintaining a tidy, productive environment.

Setting Up a Dedicated Space for 3D Printing

The first step in building your 3D printing workshop is choosing the right location. Ideally, this should be a space with good ventilation, stable surfaces, and minimal dust. Popular choices include garages, basements, spare rooms, or even a dedicated corner of a home office. When selecting a spot, consider the noise generated by printers, as some models can be loud during operation.

Once you’ve picked a location, ensure your workspace has a sturdy table or bench that can support the weight of your printer and resist vibrations during printing. A level surface is crucial to ensure consistent prints and prevent unnecessary wear on your machine. If possible, position your setup near a power outlet, as most 3D printers and accessories require electricity.

Adding shelves or storage units nearby is also a smart move. These can house filaments, tools, and maintenance supplies, keeping everything within easy reach. For more inspiration on setting up a 3D printing workspace, visit Maker’s Muse.

Essential Tools and Accessories for a Home Workshop

Beyond the printer itself, a home 3D printing workshop requires various tools and accessories to keep things running smoothly. Some must-haves include:

- Filament Storage: Airtight containers with desiccant packets help prevent filament from absorbing moisture, which can ruin print quality.

- Cleaning and Maintenance Tools: Nozzle cleaning needles, brushes, and a scraper are essential for maintaining your printer and removing prints from the build plate.

- Post-Processing Tools: Sandpaper, files, hobby knives, and a rotary tool are useful for finishing and refining prints.

- Digital Caliper: This tool helps you measure dimensions precisely, especially when troubleshooting calibration issues or working with custom designs.

- Glue Stick or Adhesion Aids: For improving bed adhesion, these simple tools are invaluable.

A magnifying lamp or good lighting can also make a big difference when inspecting prints or performing repairs. A detailed tool guide can be found at All3DP.

Safety Considerations and Best Practices

Safety is a crucial aspect of 3D printing that shouldn’t be overlooked. While most consumer-grade printers are designed with hobbyists in mind, certain precautions are necessary.

Proper ventilation is essential, especially when printing materials like ABS, which can release potentially harmful fumes. Set up your workspace in a well-ventilated area or use an enclosure with an exhaust system to direct fumes outdoors. Resin printers, in particular, require gloves and goggles when handling resin, as it can irritate skin and eyes.

Fire safety is another consideration. Avoid leaving your printer unattended for long periods, and make sure it’s placed on a non-flammable surface. Some hobbyists add smoke detectors or fire extinguishers to their workshops for added peace of mind.

Organized wiring and cable management are also critical for preventing accidents. Keep cables neat and secured to avoid tripping hazards or accidental damage. For comprehensive safety tips, check out Prusa Research’s Safety Guide.

Tips for Organizing and Maintaining Your Workspace

A clean and organized workshop not only looks better but also improves efficiency and reduces frustration. Start by grouping your tools, filaments, and accessories logically. Labeling storage containers or drawers makes it easy to find what you need without rummaging.

Filament storage is particularly important. Keep filaments in airtight containers with silica gel packets to prevent moisture from degrading their quality. Wall-mounted filament holders or racks can save space and keep materials accessible.

Regular maintenance of your printer and workspace is equally vital. Clean your printer’s build plate after every use, inspect belts and screws for wear, and lubricate moving parts as needed. Dusting and vacuuming your workspace can help prevent debris from affecting print quality.

For ideas on workspace organization, visit Thingiverse for 3D-printable storage solutions tailored to your tools and accessories.

Building a home workshop for 3D printing is a rewarding project that enhances your creative capabilities and streamlines the printing process. By selecting the right location, equipping your space with essential tools, prioritizing safety, and maintaining organization, you’ll create an efficient, inspiring environment for all your 3D printing adventures. With the right setup, your workshop becomes more than just a workspace—it’s a hub for innovation and creativity. Let’s start printing!

Exploring Open-Source 3D Printing

Open-source 3D printing has played a transformative role in democratizing access to this powerful technology. By embracing open-source principles, hobbyists gain access to affordable, customizable tools and software, while contributing to a global community of makers and innovators. Let’s explore the benefits of open-source 3D printing, popular models, community-driven projects, and ways to get involved in this thriving ecosystem.

Benefits of Using Open-Source 3D Printers and Software

The open-source approach provides significant advantages for hobbyists and professionals alike. The most immediate benefit is cost-effectiveness. Open-source 3D printers and software are often more affordable than their proprietary counterparts because they’re developed collaboratively, without the high licensing fees associated with closed systems.

Another major advantage is customizability. Open-source hardware and software allow users to modify designs, firmware, and settings to meet their specific needs. Whether you’re tweaking the mechanics of a printer to improve performance or altering software to handle unique materials, open-source solutions offer unmatched flexibility.

Transparency is another hallmark of open-source technology. With access to complete design files and code, users can understand exactly how their machines and software work. This fosters a deeper understanding of the technology and enables users to troubleshoot and fix issues independently.

Finally, the collaborative nature of open-source projects means that advancements benefit the entire community. New features, improvements, and innovations are often shared freely, driving rapid progress and making cutting-edge technologies accessible to everyone.

For more on the philosophy and impact of open-source 3D printing, visit Open Source Ecology.

Popular Open-Source 3D Printer Models

Several open-source 3D printer models have become favorites among hobbyists for their affordability, versatility, and community support. One of the most iconic is the Prusa i3 series, developed by Prusa Research. Known for its reliability and high-quality prints, the Prusa i3 is fully open-source, allowing users to modify and improve both the hardware and firmware.

The Creality Ender 3 is another highly popular open-source printer. Its low cost and robust design have made it a go-to option for beginners and experienced makers alike. The Ender 3’s open-source firmware allows for upgrades like auto-bed leveling and filament runout sensors, extending its capabilities far beyond its base model.

Other noteworthy models include the LulzBot TAZ series, which is praised for its modular design and compatibility with a wide range of filaments, and the Voron series, a high-performance open-source printer designed for advanced users who prefer to build their machines from scratch.

For a comprehensive list of open-source printers, check out RepRap, the project that sparked the modern open-source 3D printing movement.

Community-Driven Projects and Collaborations

One of the most exciting aspects of open-source 3D printing is the vibrant, collaborative community that surrounds it. Community-driven projects often focus on solving real-world problems, from creating low-cost prosthetics to developing tools for disaster relief.

For example, the e-NABLE project uses open-source designs to create affordable, 3D-printed prosthetic hands and arms for people in need. This initiative has empowered volunteers around the world to contribute their skills and resources to a meaningful cause.

Another inspiring project is the Open Source Ecology initiative, which focuses on developing a library of open-source tools for sustainable living, including designs for 3D printers and related equipment.

Collaborations also thrive in platforms like Thingiverse and MyMiniFactory, where users share, remix, and improve designs. These platforms serve as hubs for creativity, innovation, and skill-sharing, enabling makers to connect and collaborate globally.

How to Contribute to the Open-Source 3D Printing Community

Becoming an active member of the open-source 3D printing community is a rewarding way to give back and help advance the technology. There are many ways to contribute, depending on your skills and interests:

- Share Designs: Upload your 3D models to platforms like Thingiverse or Cults, where others can use and adapt them for their projects. Include detailed instructions and licensing information to encourage collaboration.

- Develop Software or Firmware: If you have programming skills, consider contributing to open-source software projects like Marlin (a popular firmware) or slicers like Cura. These contributions can help improve features, fix bugs, or expand compatibility.

- Document and Share Modifications: Many hobbyists develop creative modifications for their printers. Documenting these mods and sharing them online can inspire others and improve the capabilities of open-source hardware.

- Participate in Forums: Online forums like Reddit’s r/3Dprinting and the Prusa community forums are great places to share knowledge, troubleshoot problems, and engage with fellow makers.

- Join Open-Source Initiatives: Projects like e-NABLE and Open Source Ecology often welcome new contributors. Volunteering your time and expertise can make a tangible impact.

For resources and opportunities to get involved, visit GitHub, a central platform for open-source software development.

A Community-Driven Future

Open-source 3D printing is more than just a technology—it’s a movement that empowers individuals, fosters collaboration, and drives innovation. By embracing open-source tools, contributing to community projects, and sharing knowledge, hobbyists can play a vital role in shaping the future of 3D printing. Whether you’re improving a design, coding new features, or simply sharing your experiences, every contribution strengthens the community and helps push the boundaries of what’s possible.

Combining 3D Printing with Other Hobbies

3D printing is a versatile tool that can seamlessly integrate with other hobbies, opening up new creative possibilities and enhancing projects in ways that were once unimaginable. By combining 3D printing with disciplines like electronics, woodworking, and crafting, hobbyists can tackle multi-disciplinary projects that blend technical innovation with hands-on artistry. Let’s dive into how 3D printing can complement existing hobbies, showcase inspiring projects, and explore opportunities for collaboration within the broader maker community.

Integrating 3D Printing with Other Hobbies

One of the most exciting aspects of 3D printing is its ability to complement and enhance other hobbies. For example, if you’re into electronics, 3D printing allows you to create custom enclosures for Arduino projects, Raspberry Pi cases, or even parts for drones and robots. With precise designs, you can ensure your components are securely housed while achieving a polished, professional look.

In woodworking, 3D printing can be used to fabricate custom jigs, clamps, or decorative inlays. Imagine adding intricate 3D-printed embellishments to a handcrafted piece of furniture or creating a tool holder perfectly tailored to your workshop needs.

For crafting and DIY enthusiasts, 3D printing opens up endless opportunities for personalization. From cookie cutters and jewelry molds to unique tools like embossing rollers or pattern stamps, the technology can take your projects to the next level. Even hobbies like gardening can benefit, with custom planters, irrigation systems, or birdhouses designed to your exact specifications.

Examples of Multi-Disciplinary Projects

The intersection of 3D printing with other hobbies has inspired countless innovative projects. Here are some real-world examples:

- Electronics + 3D Printing:

Hobbyists have designed and printed modular robotic arms powered by Arduino microcontrollers. These arms can perform tasks like picking up objects or drawing, blending mechanical engineering with programming and design. - Woodworking + 3D Printing:

A woodworker combined their craft with 3D printing to create a chessboard with intricate, 3D-printed chess pieces. The board itself was made of fine wood, while the pieces were detailed and custom-designed to reflect a futuristic aesthetic. - Costume Design + 3D Printing:

Cosplayers often use 3D printing to create armor, props, and accessories for their costumes. These pieces are then painted and finished to look incredibly realistic, combining traditional crafting techniques with cutting-edge technology. - Gaming + 3D Printing:

Tabletop gaming enthusiasts have embraced 3D printing to create custom miniatures, dice towers, and terrain pieces. These elements add depth and immersion to games, allowing players to craft unique settings and characters.

For inspiration and downloadable designs, check out Thingiverse or MyMiniFactory.

How 3D Printing Can Enhance Your Existing Hobbies

3D printing enhances hobbies by providing precision, customization, and access to tools or components that might otherwise be unavailable. For example, imagine you’re an amateur photographer. A 3D printer can help you create custom lens caps, tripod mounts, or even light modifiers.

Similarly, 3D printing can improve efficiency and problem-solving within your hobbies. Woodworkers can print measuring tools or angle guides, while gardeners might create specialized seed trays or supports for climbing plants. The ability to prototype and iterate quickly makes 3D printing an invaluable addition to any hobbyist’s toolkit.

For DIY repair enthusiasts, 3D printing can be a lifesaver. Broken parts for appliances, toys, or tools can often be modeled and replaced with 3D-printed components, saving time and money while reducing waste.

Collaboration Opportunities Within Hobbyist Communities

The maker community thrives on collaboration, and 3D printing enthusiasts are often eager to share knowledge, designs, and techniques. Collaboration opportunities abound, whether through local maker spaces, online forums, or social media groups.

For instance, woodworking clubs might collaborate with 3D printing groups to create hybrid furniture projects, while electronics hobbyists might team up with 3D printing enthusiasts to build robots or gadgets. Events like Maker Faires provide excellent opportunities to connect with others and showcase multi-disciplinary projects.

Online platforms like Instructables offer step-by-step guides for collaborative projects, while forums like Reddit’s r/3Dprinting are great places to share ideas and find like-minded hobbyists.

Conclusion

Combining 3D printing with other hobbies unlocks new creative possibilities and enhances your ability to innovate. Whether you’re crafting, woodworking, gaming, or building electronics, 3D printing serves as a bridge between traditional techniques and modern technology. By embracing multi-disciplinary projects and collaborating with others in the maker community, you’ll not only broaden your skills but also bring your ideas to life in exciting, unexpected ways. Let your imagination guide you, and enjoy the journey of blending hobbies into something truly unique.