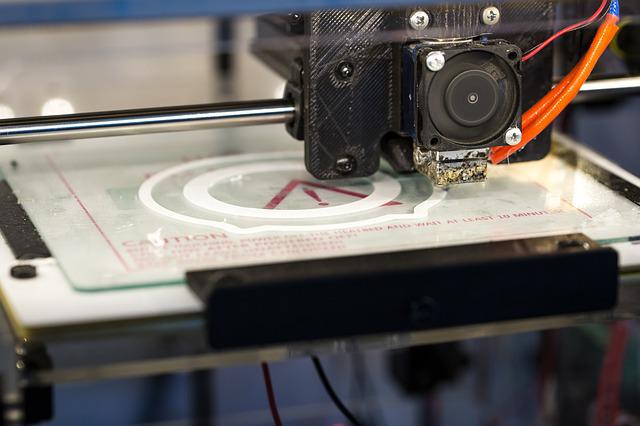

3D printing and technology together will revolutionize the way we make things. It has already changed the way prototypes are made and how parts are manufactured. Now, it is even starting to change how finished products are made. 3D printing allows you to create custom objects from scratch. You can make anything from small personalized items to lipstick cases and even a replica of the Eiffel Tower.

According to an Accenture report, manufacturing ecosystems are changing, becoming hyper-connected and distributed. The IoT is the most significant enabler of this change, allowing for systems that link thousands of “smart” devices. With the adoption of additive manufacturing (3D printing) and smart sensors, the designs are becoming increasingly intelligent and interconnected. At the heart of every manufacturing, the ecosystem is a supply chain. Supply chains may be more connected than ever, but what else is changing?

The potential of 3D printing is as vast as it is exciting. From the ability to create new organs to 3D printed houses, this technology has incredible potential to ultimately change how we make things. This method is also increasingly used for later manufacturing instead of traditional injection molding and other techniques that use injection-molding machines. 3D printing allows for creating complicated shapes and often produces parts stronger than molding equivalents.

3D Printing Technology Has Changed Prototypes

3D printing has made a massive impact on the prototyping process. In the past, prototypes were often hand-crafted, which was both time-consuming and expensive. With 3D printing, prototypes can be created quickly and cheaply. This has allowed businesses to create more prototypes in a shorter time, which means they can test new ideas faster and iterate on them more quickly. As a result, 3D printing has enabled businesses to bring new products to market faster than ever before.

3D Printing Changed Manufacturing?

Regarding modern manufacturing, few technologies have had as big of an impact as 3D printing. This additive manufacturing process has changed the way parts are made, offering new opportunities for design and customization. People can easily create complex shapes, and 3D printing can also be used to create functional parts with moving components.

3D Printing Has Changed Finished Products

3D printing is beginning to change the way products are made. With 3D printing, manufacturers can create more customized products using less material. This technology is also becoming more affordable, making it a viable option for small businesses and individuals.

3D Printing And Technologies Benefits

3D printing can help manufacturers streamline production. For example, 3-D printing reduces the need for mass production in industries like automotive by making custom products. This allows manufacturers to create more customized parts, lowering overall production costs. They can also create smaller runs, reducing the storage cost for unused products.

3D Printing Challenges

Although 3D printing can benefit manufacturers, the technology has some challenges. Car manufacturers are already using 3D printing to make prototype parts, but the technology can create numerous impossible products with traditional manufacturing. 3D printing is also reducing waste and meeting other environmental goals. Currently, the biggest challenge for 3D printing is creating durable parts. If a part breaks, it is no longer useful. However, this problem is being resolved by increased innovation in technology.

For example, with 3D printing, a business can create a whole new product to sell, rather than just a few prototype parts. Because the product can be made from a design file, the product can be customized for a specific customer. Small companies with a minimal workforce can now create products from designs on their own. For example, a company could develop and produce custom-made snowboards without hiring an outside manufacturer. Read more about how 3D printing is changing manufacturing: How 3D printing is starting to change how finished products are made.

3D printing is beginning to change the way products are made. With 3D printing, manufacturers can create more customized products using less material. This technology is also becoming more affordable, making it a viable option for small businesses and individuals. At the same time, 3D-printing technology is also used to make more traditional products.

The Handy-Dart 3D-printed Gun.

Handy-Dart is one example. The company uses selective laser sintering, which builds objects through tiny layers of powdered materials. While this type of gun has limited functionality, it is a step toward 3D-printed firearms that are more lethal. Other technologies are also used to make new products. One of the most popular alternative manufacturing processes is laser cutting, which can be used to create various products, both 2D and 3D.

Many people also use 3D modeling to design their product on a computer and find a company that can make it using CNC (computer numerical control) machines or CNC mills. Using a computer to design products is nothing new, but computer software and hardware advancements make it easier for businesses to use 3D printing. Modern printers can print objects ranging from a few inches to a few feet in size, which is relatively inexpensive compared to traditional manufacturing. One of the biggest challenges to 3D printing is that users must create a digital model of the object they want to print.

What will the next advancement be? 3D printers create not just manufactured items but fully functioning organs, bones, and body parts.

This post was proofread by Grammarly!

Researchers have used 3D printers to create human skin, cartilage, ears, and teeth. Other experimenters are working on printing human organs and body parts for transplant patients.

Start [HERE] 3D printing!

We would love to know what you think of your new products. Would you do us a favor and leave a comment if you have a moment?

It enables us to improve upon everything we do. Still, it also helps us decide which products to research and promote.

We’ve made leaving a comment or question easy! Just go below.

Some of the links in this article are affiliate links. If you were to buy something after clicking on one of these links, I would get a small commission that might help me get a new printer for the shop!

Thanks for being part of the community!

Bullwinkle

Hello,

As an eCommerce seller, the first physical touchpoint you’ll have with a customer is when your package arrives at their door, an impactful impression is critical.

Fulfillment marketing, a cutting-edge solution crafted by my friends over at The Fulfillment Lab, is designed to make the unboxing experience memorable by bringing marketing and fulfillment together at scale!

With this strategy, you can create a unique order fulfillment experience using data you’re already capturing—without sacrificing speed or scalability. It makes it possible to:

- Build brand recognition. With increasing competition for eCommerce businesses, you need a way to differentiate and build brand recognition. Fulfillment marketing is that solution!

- Tailor the customer experience. Personalize the fulfillment experience to each buyer using marketing data you’re already collecting—delivering a unique customer experience that’ll leave a lasting impression.

- Create brand advocates. Turn one-time buyers into repeat buyers and loyal advocates for your brand. You make it easier to attract new customers driving additional revenue from repeat sales while expanding your new customer base.

I figured you’d like to do this in your organization, so I’m connecting you with The Fulfillment Lab! Click this link [HERE] to get started with their fulfillment services today, or contact them directly if you have more questions.

The Fulfillment Lab, 5136 W Clifton St, Tampa, FL 33634, (813) 444-3455