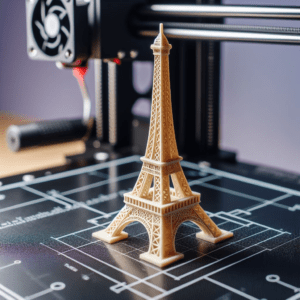

Welcome to the incredible world of 3D printing! Envision a machine that can create objects, layer by layer, right before your eyes. Unlike traditional methods that carve out shapes from blocks of material, 3D printing builds up structures one layer at a time.

This process, known as additive manufacturing, is not just changing the way we make things, but also sparking a wave of creativity and innovation. If you’re new to this technology, you’re in the right place. We’ll guide you through the basics of 3D printing, making it simple and exciting!

Layer-based Manufacturing: Are you familiar with how objects can be built layer by layer instead of traditional subtractive methods? In layer-based manufacturing, also known as additive manufacturing, objects are created by adding material layer by layer, as opposed to conventional methods that carve out shapes from blocks of material. This innovative process is changing the way we think about making things.

What Is 3D Printing?

3D printing, officially known as additive manufacturing, is a revolutionary process that involves creating three-dimensional objects by depositing successive layers of material. To visualize this process, think of stacking pancakes to build a tower.

In the same way, a 3D printer progressively adds material until the entire object is formed. This innovative technology enables the production of intricate and precisely designed shapes that are often challenging to manufacture using traditional methods.

How Does a 3D Printer Work?

A 3D printer interprets instructions from a digital file to produce a tangible object. This digital file guides the printer, stipulating the placement and composition of each material layer. The materials used in 3D printing include plastic, metal, ceramics, and even food.

Here’s a simple breakdown of the process:

1. Design the Model: Use software to create a 3D model of the object you want to print.

2. Prepare the Printer: Load the material and ensure the printer is ready to go.

3. Print the Object: The printer follows the digital file, layer by layer, until the object is complete.

4. Finish the Print: Remove the object from the printer and perform any necessary finishing touches.

A Brief History of 3D Printing

The idea of 3D printing has existed since the 1980s, and over the years, it has become increasingly accessible to people. Initially utilized for industrial prototyping, 3D printers are now available for hobbyists and educational institutions.

This widespread availability of technology has not only transformed 3D printing into a feasible option for individuals. Still, it has also ignited a surge of innovation, with individuals experimenting with printing various items such as toys and tools. You are an integral part of this flourishing community of 3D printing enthusiasts!

The Magic Behind the Layers: Understanding the Technology

Types of 3D Printers

There are several 3D printers, each using a different method to create objects. Let’s explore some of the most common ones:

– Fused Deposition Modeling (FDM): This is the most popular type of 3D printer for beginners. It works by melting plastic filament and extruding it layer by layer.

– Stereolithography (SLA): This type uses a laser to harden liquid resin, creating a solid object.

– Selective Laser Sintering (SLS): Similar to SLA, but it uses a laser to fuse powdered material, like nylon or metal, into solid shapes.

Materials Used in 3D Printing

The selection of materials in 3D printing plays a crucial role in determining the strength, flexibility, and aesthetic qualities of the printed item. The range of materials available for 3D printing is remarkably diverse and versatile.

These materials encompass biodegradable plastics derived from renewable sources such as corn starch, as well as robust and long-lasting plastics commonly employed in the production of toys like LEGO bricks.

– PLA (Polylactic Acid): A biodegradable plastic made from renewable resources like corn starch. It’s easy to use and great for beginners.

– ABS (Acrylonitrile Butadiene Styrene): A strong and durable plastic often used for toys like LEGO bricks.

– Resin: Used in SLA printers, it provides high detail and a smooth finish.

– Nylon: Known for its strength and flexibility, making it suitable for functional parts.

The Software: Designing Your 3D Model

Creating a 3D model requires special software. Luckily, there are many user-friendly options available, even for beginners:

– Tinkercad: A free, web-based application that’s perfect for newcomers.

– Fusion 360: Offers more advanced tools for designing complex models.

– Blender: A powerful, open-source software for creating detailed models and animations.

Adventurer 5M- Get $20 Off with Code SA5M! Now Only $379.00

From Imagination to Creation: The Printing Process

Step 1: Designing Your Object

Before printing, you need a digital model of your object. This can be done by:

- Designing from Scratch: Use software like Tinkercad to create your own designs.

- Downloading from Libraries: Websites like Thingiverse offer thousands of free designs ready to print.

Step 2: Preparing the Printer

Once your design is ready, it's time to set up the printer. Here's how:

- Load the Filament: Ensure the correct material is loaded into the printer.

- Level the Bed: Make sure the print bed is level to ensure even layers.

- Adjust the Settings: Configure the printer settings, such as temperature and speed, according to the material used.

Step 3: Printing the Object

With everything set up, you can start the print. This is where the magic happens! The printer follows the digital file, building your object layer by layer.

Step 4: Post-Processing

Once the print is complete, you may need to do some finishing touches:

- Removing Supports: Some designs require supports that must be removed after printing.

- Sanding and Polishing: To smooth out surfaces and enhance the appearance.

- Painting or Coating: Adding color or protective coatings to your object.

Applications of 3D Printing: A World of Possibilities

3D printing is increasingly becoming a part of everyday life, extending beyond traditional uses in engineering and art. It offers surprising applications in various aspects of daily living:

- Personalized Phone Cases: Customize your device with exclusive designs tailored to your taste.

- Home Decoration: Bring your unique style to life by 3D printing vases, lamps, and other decorative items.

- Toys and Games: Engage children with custom-designed, fun, and educational 3D-printed toys.

Education and Learning

Educational institutions are increasingly adopting 3D printing to enhance the teaching of STEM subjects (Science, Technology, Engineering, and Mathematics). This technology allows students to create and print their own designs, transforming theoretical concepts into physical, tangible objects.

Medical Marvels

Advancements in the medical field have led to the use of 3D printing for the creation of custom prosthetics, implants, and even organs. This innovative technology enables the development of personalized medical solutions, ultimately improving patient outcomes.

Industry and Manufacturing

3D printing is widely used in industries for rapid prototyping, which allows for quick testing and refinement of products. It also makes it possible to create complex parts that would be difficult or impossible to produce using traditional manufacturing methods.

Troubleshooting and Tips: Becoming a 3D Printing Pro

Common Issues and Solutions

Starting with 3D printing can be challenging, but don't worry! Here are some common issues and how to solve them:

1. Warping: Warping happens when the edges of the print start to curl up, leading to an uneven surface and potential printing issues. This can be prevented by ensuring that the print bed is properly leveled and heated to the appropriate temperature. Additionally, using a heated enclosure or applying a suitable bed adhesive can also help in minimizing warping.

2. Clogged Nozzle: A clogged nozzle can result in interrupted or uneven extrusion of the printing material. To prevent this, regular maintenance and cleaning of the printer's nozzle are essential. Using cleaning filament or a fine needle to clear any obstructions can help maintain optimal nozzle performance.

3. Poor Adhesion: Adequate adhesion of the first printed layer to the build surface is crucial for successful 3D printing. If the first layer doesn't adhere properly, adjustments to the bed temperature or the use of additional adhesives such as a glue stick, painter's tape, or specialized bed adhesion sheets can improve the adhesion quality and ensure a successful print.

Tips for Better Printing

Looking to enhance your 3D printing expertise? Consider these comprehensive tips for taking your skills to the next level:

- Dive into Settings: Take the time to fine-tune print settings such as layer height, infill density, and print speed to achieve optimal results for your specific printer and materials. Don't hesitate to experiment with different configurations to uncover the perfect combination.

- Invest in a Reliable Power Supply: To ensure seamless printing and avoid any potential disruptions, it's crucial to utilize a stable and trustworthy power source. This will contribute to the overall quality and consistency of your 3D prints.

- Engage with Online Communities: Harness the power of online platforms such as Reddit, Facebook groups, and dedicated forums to tap into a wealth of knowledge and expertise. Engaging with experienced enthusiasts can provide invaluable insights, troubleshooting assistance, and support to aid in your 3D printing journey. Embracing these communities can lead to valuable connections and the exchange of best practices.

The Future of 3D Printing: Endless Possibilities

Innovations on the Horizon

The future of 3D printing is incredibly promising and bursting with potential. Check out these thrilling trends to keep an eye on:

- Bioprinting: Pioneering the creation of living tissues and organs for life-saving medical applications.

- Sustainable Printing: Embracing recycled materials and eco-friendly techniques to revolutionize manufacturing.

- Mass Customization: Empowering consumers to uniquely personalize products on a massive scale.

How You Can Get Involved

Whether you're a hobbyist or an aspiring professional, there are many ways to dive deeper into the world of 3D printing:

- Join a Maker Space: These community workshops provide access to equipment and resources.

- Take Online Courses: Websites like Coursera and Udemy offer courses on 3D design and printing.

- Start a Project: Use your skills to create something unique, whether it's a new invention or a piece of art.

Adventurer 5M Fash Sale- Get $100 Off! Now Only $299. (US Only)

Start Your 3D Printing Adventure

Congratulations! You've taken the first step into the exciting world of 3D printing. From designing your models to watching them come to life, this technology offers endless possibilities.

Remember, every expert was once a beginner. With practice and patience, you'll soon be creating amazing things with your 3D printer. So, what are you waiting for? Unleash your creativity and start your 3D printing adventure today!

Bullwinkle