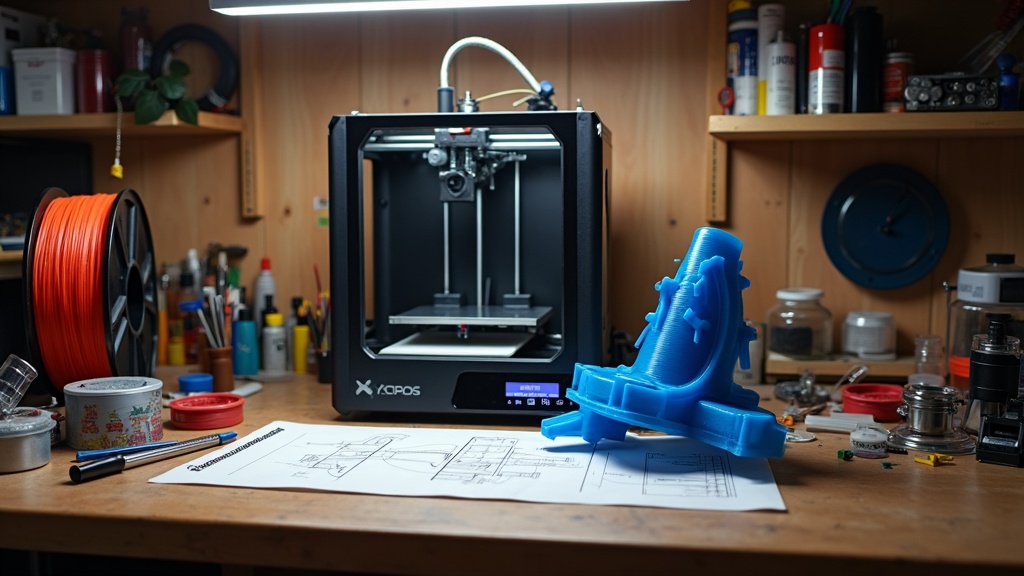

Sometimes, innovation comes from the most unexpected places. A tiny idea, a spare garage, and a whole lot of late-night trial and error can lead to something amazing. The story of someone 3D printing a groundbreaking part in their garage and catching the eye of NASA is a real testament to how creative problem-solving can open doors that you didn’t even know existed. In this article, I’ll share this tale, why it matters, and what it means for anyone curious about blending 3D printing with ambitious dreams like aerospace.

How a Garage Breakthrough Got NASA’s Attention

Home workshops aren’t usually the first thing that comes to mind when thinking about space technology. But every once in a while, a clever experiment in someone’s garage really does become something much bigger. In this case, a hobbyist with a passion for engineering and a basic desktop 3D printer created a prototype of a component that solved a long-standing problem. Space agencies had struggled with this issue for years, but this new approach offered a fresh solution.

This particular inventor wasn’t working with fancy degrees or high-tech labs. Instead, a steady curiosity and a willingness to fail (often and loudly) pushed the project forward. Each failed print offered important lessons. After about a hundred iterations—with a mountain of broken plastic—he built a working prototype that passed some serious backyard stress tests. He shared the project on a small online maker forum, not expecting much. Within weeks, the design spread through 3D printing communities, eventually reaching NASA engineers who were hunting for resourceful ideas to tackle a persistent challenge.

What Was So Special About This 3D Printed Part?

This wasn’t just any trinket or model. The part was a compact, lightweight, and incredibly resilient connector meant for use in harsh environments, just like those onboard spacecraft. In aerospace, creating such parts typically takes months, with painstaking and expensive manufacturing involved. Thanks to clever design tweaks and easily available materials, this DIY version worked just as well in stress tests as traditional ones, but at a fraction of the cost and development time.

The connector addressed an age-old problem: how to link flexible hoses and wiring while preventing leaks, even when temperatures swing wildly and vibrations are constant. Rather than using metals, the garage inventor worked with specialized high-temp plastics blended with carbon fiber strands, which could be found on regular 3D printing spools. The design used geometric locking instead of tight threading, so maintenance was much easier—even for astronauts in gloves. For NASA, this was crucial, especially since reducing launch costs and improving reliability with modular, fixable components is always a priority.

The Impact of Taking 3D Printing Beyond Hobby Projects

NASA’s interest in a homegrown 3D printed part makes a clear point. The lines between hobbyists and professionals keep blurring, especially since 3D printers are now affordable for anyone willing to learn. What made this project stand out wasn’t just the usefulness of the part, but how openly the development process was shared online. The inventor documented every step, from research to failures and trade-offs, in public forums. NASA engineers quickly understood the logic and replicated the results without guessing or dealing with proprietary roadblocks.

There’s a key lesson here: sharing details, even about mistakes, can make your work more valuable—and increase the chances you’ll connect with bigger organizations or fans. Open source projects and collaborative building are becoming the norm, with massive agencies tapping into this open innovation scene. Forums today are full of people pitching in to improve files, tweak print settings, and try new materials, which helps everyone boost their learning curve.

How Garage Tinkering Stacks Up to Traditional Aerospace

Building aerospace parts always sounded exclusive, like you need a million-dollar budget and a team of experts. While that’s still true for launching rockets, prototyping and testing smaller parts is possible in garages now, thanks to reliable, high-resolution home 3D printers and off-the-shelf specialty filaments. Professionals may use laser sintering or metal printing, but midrange filament printers certainly get impressive results if you know your machine’s ins and outs. Here’s how 3D printing at home compares:

- Speed: Printing and testing a new version the same night eliminates long waits.

- Cost: Plastics and composites are far cheaper than traditional machining, so experimentation carries much less risk.

- Customization: Changing the design is as easy as editing a digital file, which is key for unique shapes or internal features.

- Collaboration: Digital designs are easy to share and get quick feedback—helpful for projects bigger manufacturers might overlook.

NASA already uses 3D printed parts onboard the International Space Station (ISS) from commercial suppliers. However, this new approach opens the door for anyone willing to put in real work to contribute designs to missions or experiments, making aerospace far more inclusive.

Tips for Innovative 3D Printing at Home

If you want to try your hand at 3D printing parts that could solve real problems, structured practice goes a long way. Here’s some straightforward advice:

- Start Simple: Get familiar with your printer—figure out its tolerances, supported materials, and quirks.

- Pick Smart Materials: Not all plastics are equal; some are brittle, others strong, flexible, or heat resistant.

- Iterate Relentlessly: Don’t worry about early failures. Every misprint reveals something about your design or settings.

- Test for Reality: Use stress, heat, and vibration tests similar to those in the target environment.

- Share and Connect: Posting progress online speeds up learning and may even attract unexpected attention.

Challenges You Might Face, and How to Dodge Them

Every garage project has hurdles. When building high-performance parts, especially for NASA, challenges multiply, but they’re manageable. Common roadblocks include:

- Material Choices: Not all materials for home printing have the right certifications for aerospace. Use the best you can find and track new options from filament companies.

- Printer Accuracy: Consumer printers have precision limits. Calibrate often, and consider upgrading critical components now and then, like the nozzle or hot end.

- Certification and Thorough Testing: If you aim to get designs noticed by pros, you’ll need solid documentation and test data. Saving your tests builds trust.

- Intellectual Property: Design rights can be tricky. Open sharing helps the community, but use Creative Commons or other licenses if you want credit.

Testing Prototypes Like a Pro

Printing the part is only half the job; proving it works is just as important. Even backyard tests can provide useful data:

- Use home ovens (with safety precautions) to simulate temperature swings.

- Try vibration by attaching parts to electric sanders.

- Use weights or cords for load and flex testing.

These at-home experiments are fun and, when documented well, can help show experts you’ve thought things through.

How 3D Printing Is Changing Space Exploration for Good

Widespread, skilled 3D printing is making a lasting impact. For NASA and similar organizations, it’s not just about saving money or time. The ability to tweak, fix, or reprint parts during a mission truly changes the game. There are firsthand accounts of astronauts receiving digital files from Houston and printing replacement tools or brackets on the ISS—no need to wait for a rocket delivery. Fast prototyping, championed by home inventors, makes this possible.

NASA has launched public contests and grant programs inviting everyday people to submit digital designs for mission hardware. This shows they’re committed to pulling ideas from the maker community. The process typically involves reading some design rules, running basic tests, and uploading a digital file—steps that are manageable for most enthusiasts.

Real-World Benefits and Everyday Uses

Breakthroughs in home garages have ripple effects far beyond aerospace. Here are a few ways 3D printing has impacted other fields:

- Medical Devices: Fast prototyping allows for custom braces, prosthetics, and surgical tools tailored to individual needs.

- Automotive Repairs: Car lovers can print hard-to-find or discontinued parts, making restoration projects more feasible.

- DIY Savvy: Everything from custom adapters for electronics to unique camera mounts is easier thanks to the trial-and-error mindset inspired by home inventors.

Frequently Asked Questions

Question: How do I get started if I want to design aerospace parts at home?

Answer: Begin by practicing simple mechanical designs and learning to print with high-strength materials. Build up your skills with real-world stress tests and share your work online. You never know who’s paying attention.

Question: What kind of 3D printer is good enough to prototype real engineering parts?

Answer: Many solid desktop FDM (fused deposition modeling) printers work well. Look for strong frames, heated beds, and support for advanced materials like carbon fiber-infused filaments.

Question: Can I legally share my designs with NASA or other agencies?

Answer: Yes. NASA sometimes organizes open calls for design ideas and even runs challenges where anyone can participate. Just check the current guidelines before submitting your files.

Question: How do I make sure my ideas get credit?

Answer: Use open licenses or Creative Commons marks to signal your intent. Keeping digital records and sharing on well-known platforms also helps establish authorship.

Ready to Start Your Own Garage Project?

Innovation has no dress code or official badge. By rolling up your sleeves, learning from your slip-ups, and sharing your journey, you can take even the most humble garage project to new heights. If you’re drawn to turn your 3D printer into a springboard for big ideas, remember that curiosity and openness are two of your biggest assets. Who knows? NASA’s next inquiry about a bright idea could be for something you built on your own workbench.