STL (Stereolithography) for 3D printing! It’s one of the most common file formats used in 3D printing, and for good reason. Here’s a quick rundown:

What is STL?

STL is a file format that represents the surface geometry of a 3D object. It uses a mesh of triangles to define the object’s shape, with each triangle consisting of three vertices and their connecting edges.

Why is it important for 3D printing?

- Widely compatible: Most 3D printers and slicing software support STL files, making it a versatile format for sharing and printing 3D models.

- Simple and efficient: The mesh-based representation of STL files makes them relatively simple to create and store compared to other 3D file formats. (Wikipedia explanation)

- Focuses on surface geometry: STL files only store the surface geometry of an object, not its internal details or colors. This makes them suitable for 3D printing, which only cares about the physical shape of the object.

However, there are some limitations to STL files

- No support for internal details: As mentioned, STL files only store the surface geometry, so they cannot represent internal structures like holes, channels, or threads. These features need to be designed separately or added later in the 3D printing process.

- Potential for errors: The mesh-based representation can sometimes lead to errors, such as non-manifold surfaces or watertightness issues. These errors can cause problems during 3D printing.

- Large file size: Complex models can result in large STL files due to the high number of triangles required to represent their surface.

Overall, STL remains a valuable and widely used format for 3D printing. Its simplicity, compatibility, and focus on surface geometry make it a good choice for a variety of applications. However, it’s important to be aware of its limitations and choose the appropriate format based on your specific needs.

Limitations of STL

While STL is a great format for many 3D printing applications, it does have some limitations:

- Not the most efficient format: STL files can be quite large, especially for complex objects. This can make them slow to slice and print.

- Limited support for advanced features: STL files don’t support features like color, multiple materials, or textures.

- Can be prone to errors: STL files can sometimes contain errors that can cause problems during printing.

OBJ (Wavefront Object) is another popular file format used in 3D printing alongside STL. While both play crucial roles in the realm of additive manufacturing, they cater to different situations and offer distinct advantages. Let’s delve into the world of OBJ:

What is OBJ?

Unlike STL, which focuses solely on the surface geometry of a 3D object, OBJ is more comprehensive. It defines the object using multiple components:

- Vertices: Points in 3D space that mark the corners of the object.

- Faces: Polygons formed by connecting vertices, defining the object’s surface.

- Normals: Vectors indicating the “upward” direction of each face, crucial for lighting and shading.

- Texture coordinates: Map textures onto the object’s surface for visual details.

This additional information makes OBJ a more versatile format compared to STL.

Strengths of OBJ

- Preserves details: Unlike STL, OBJ can store texture coordinates, allowing for multi-colored printing and intricate surface patterns.

- Better for complex models: Objects with curved surfaces or smooth transitions are often represented more accurately in OBJ than STL.

- Supports additional features: OBJ sometimes includes information about materials, allowing for advanced printing techniques.

Limitations of OBJ

- Not universally compatible: While widely used, some older 3D printers and slicing software might not support OBJ natively.

- Size can be an issue: Complex models with extensive textures can result in larger OBJ files, which can increase processing time.

- Conversion is sometimes needed: Depending on your workflow, you might need to convert OBJ to STL for compatibility with certain tools.

In conclusion, OBJ is a powerful format offering greater detail and flexibility compared to STL. It’s ideal for objects with complex textures, smooth surfaces, or where multi-material printing is desired. However, its wider range of information can sometimes translate to larger file sizes or compatibility limitations.

Ultimately, the choice between STL and OBJ depends on your specific project needs and the capabilities of your equipment. Feel free to ask further questions if you’d like to compare their suitability for a particular application!

I hope this helps! Feel free to ask if you have any further questions about STL or 3D printing in general.

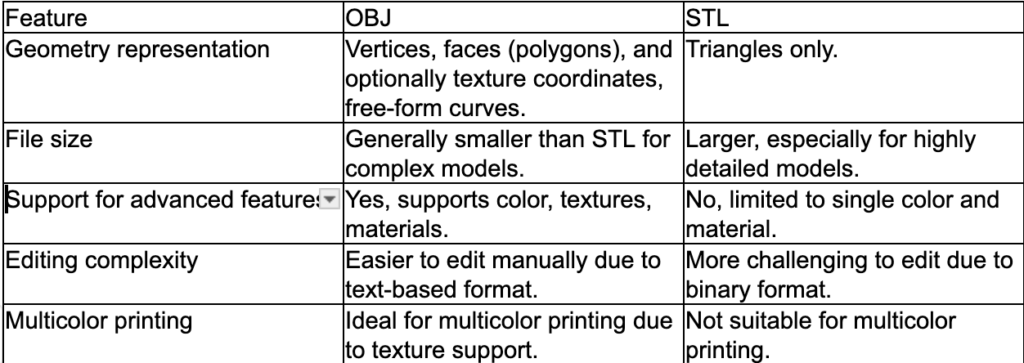

OBJ vs STL:

Similarities:

- Both represent 3D objects as collections of shapes.

- Both are widely used and compatible with most 3D printers.

- Both can be exported from 3D modeling software.

Differences:

Choosing the right format:

Use OBJ if you need multicolor printing, want a smaller file size for complex models, or need advanced features like textures and materials.

Use STL if you prefer a simple format, don’t need advanced features, or mainly print single-color objects.

Additional points about OBJ:

It’s a text-based format, making it easier to inspect and edit than the binary STL.

It can be less efficient than STL for highly detailed models due to storing extra information.

Some 3D printing software may require converting OBJ to STL before printing.

Overall, both OBJ and STL are valuable tools for 3D printing. Choosing the right format depends on your specific needs and the complexity of your model.

Feel free to ask any further questions you may have about OBJ or 3D printing in general! I’m happy to help.

Good Printing!

Bullwinkle