Understanding how a 3D printer works can help you make the most of your creations. A 3D printer (also known as an FDM 3D printer) works by heating a polymer filament until it melts and extrudes out of a nozzle, creating a solid object for the uninitiated.

The machine moves the print head to make copies of the object layer by layer. When finished, that’s your 3D print!

Understanding how a 3D printer works can help you make the most of your creations. A 3D printer (also known as an FDM 3D printer) works by heating a polymer filament until it melts and extrudes out of a nozzle, creating a solid object for the uninitiated.

However, in creating something new, it’s possible to add other melting materials to the filament and create something that melts at higher temperatures. For example, suppose the filament itself melts at around 180 degrees. In that case, it’s possible to add powdered metals to the filament, which melts at about 800 degrees, so that the resulting object is a combination of plastic and metal. The technologies vary depending on the manufacturer, but the basic principle remains the same.

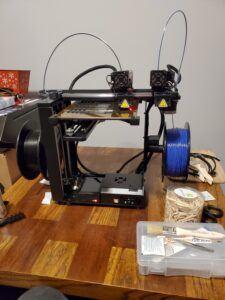

3D printing is commonly associated with desktop printers and hobbyists. Still, outside this realm, machines are used for all sorts of things, from creating custom prosthetics to building parts and prototypes for R&D in various industries. These are the most common 3D printers on the market and the most likely to be used by consumers.

The filament is fed through a filament extruder, which can be either a part of the 3D printer’s main body or a stand-alone machine. It is then heated until it melts and is extruded from a nozzle, creating a solid object. One of the main benefits of this system is that the filament can be recycled through the extruder. The technology is great for hobbyists, as the cost of 3D printers has never been lower. But for production environments, there are drawbacks.

3D printing can take anywhere from minutes to hours to complete a project. That’s fine for an object the size of a chess piece or jewelry but not great for a tool that might need to be cheap, durable, and easy to produce. The object is made when the printer deposits successive layers of melted material. We are trying to make systems to advance the frontier of 3D printing, states Mueller. Ultimately, we want to be able to create objects with moving parts.

Their current prototype model combined microprocessors, sensors, and actuators into a single 3D-printed package, then attached to a 3D-printed device. The machine moves the print head to make copies of the object layer by layer. When finished, that’s your 3D print! The process sounds like a lot to take in. It’s elementary. You’ll see how easy it is in just a few minutes. We won’t get into the details here. Please visit the wiki.

Step Three: Finished!

The beauty of this process is that it’s genuinely open-source. There is no proprietary software; you can use free software like OpenSCAD to design your object and Slic3r to create the G-code. The machine can be assembled from parts purchased on the internet for a meager price. And this machine is cheap to operate.

But the process doesn’t end there. If you use the machine to print your designs, you’ll need to clean up the object after printing. The build-up layer lines can damage the part and prevent it from working correctly.

The process of cleaning up begins with a material called painter’s tape. It’s sticky enough to grab the layer lines as you peel it off the printed object but not sticky enough to stick to the thing itself. But the process doesn’t end there. If you use the machine to print your designs, you’ll need to clean up the object after printing. The build-up layer lines can damage the part and prevent it from working correctly.

The process of cleaning up begins with a material called painter’s tape. It’s sticky enough to grab the layer lines as you peel it off the printed object but not sticky enough to stick to the thing itself. Effectively, the printer is building an object from the top down. It’s like building a sandcastle on the beach. You start with an extensive foundation and stack sand on top in layers until your sandcastle is complete.

A DIY 3D Printer

A 3D printer is a handy tool. If you build your 3D printer, the first step is to decide on the technology you want to use. 3D printing is going to change the world. It already has, and it is getting better faster than any other technology in the history of humanity.

3D printing is going to change the world. That is why I love it.

I hope you do too.

Happy 3D printing!

We would love to know what you think. Would you do us a favor and leave a comment if you have a moment?

It enables us to improve upon everything we do.

We’ve made leaving a comment or question easy! Just go below.

Some of the links in this article are affiliate links. If you were to buy something after clicking on one of these links, I would get a small commission.

Thanks for being part of the community!