The US Navy has long been a world leader in shipbuilding and technological innovation. The Navy’s new Additive Manufacturing Center of Excellence is the latest example of its commitment to staying at the forefront of technology. The center will focus on developing new ways to use 3D printing, also known as additive manufacturing, to build ships and submarines, revolutionizing how these vessels are designed and built, making them lighter, stronger, and more efficient.

The US Navy has long been a world leader in shipbuilding and technological innovation.

The US Navy has long been a world leader in shipbuilding and technological innovation. Today, that tradition continues with the opening of the Additive Manufacturing Center of Excellence.

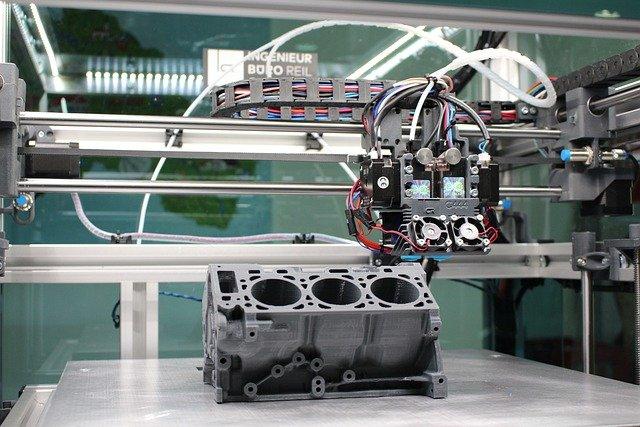

This new center, based in Virginia, will help to accelerate the use of additive manufacturing within the Navy and streamline supply chains. With three dedicated bays for additive manufacturing, this facility will serve as an operational hub for all future navy projects. Virginia Governor Glenn Youngkin opened the occasion with a speech:

“This partnership will diversify, transform and grow Southern Virginia’s production capability for the Submarine Industrial Base as well, marking another major win for Virginia’s defense economy and labor market.” Calling it a “major win” for Virginia’s economy and workforce.

The Navy’s new Additive Manufacturing Center of Excellence

With this new facility, they will be able to 3D print parts and components on demand, streamlining the supply chain and making it easier for Naval ships to get what they need. It will not only save time and money, but it will also allow the Navy to respond quickly to changing conditions or unforeseen challenges.

The center will focus on developing new ways to use 3D printing, also known as additive manufacturing, to build ships and submarines.

The US Navy’s new Additive Manufacturing Center of Excellence is now open, and it’s sure to accelerate the use of 3D printing technology within the Navy. The facility can quickly and efficiently produce parts and components for ships and submarines with three bays dedicated to additive manufacturing.

It could revolutionize how these vessels are designed and built, making them lighter, stronger, and more efficient.

The US Navy has opened its Additive Manufacturing Center of Excellence. The Navy’s new additive manufacturing center could revolutionize how these vessels are designed and built, making them lighter, stronger, and more efficient. The Virginia Governor believes this partnership will diversify, transform and grow Southern Virginia’s production capability for the Submarine Industrial Base.

The Navy’s new additive manufacturing center could revolutionize how these vessels are designed and built, making them lighter, stronger, and more efficient. The Navy is building a high-tech center dedicated to 3D printing, where designers and engineers will work together to develop new and improved parts for ships and aircraft.

Additive Manufacturing Initiative

They’ll also learn to use it as part of the White House’s educational initiative. He was among the first African-Americans to enroll in the Virginia Military Institute (VMI). In 1987-88, he conducted research for the United States Navy concerning their construction and design methods and powerful technology.

It took just days for the 3-D printer to create this complex object, which would have taken about a month for a human to finish via traditional methods. In the future, “you could imagine doing this in hours,” stated Steve Rost, an engineer at the Naval Surface Warfare Center. The glider body was made with three types of materials to test the printer’s capabilities and show its potential for future applications.

Conclusion,

This new kind of 3D printing is called Direct Digital Manufacturing, or DDM. It combines what’s known as “additive manufacturing” with a traditional computer-aided design (CAD) model. DDM allows manufacturers to skip the expensive and time-consuming process of creating and testing a series of physical prototypes while simultaneously making them stronger and lighter with the same manufacturing process.

Can You Help?

We would love to know what you think. Would you do us a favor and leave a comment if you have a moment?

It enables us to improve upon everything we do.

We’ve made leaving a comment or question easy! Just go below.

Thanks for being part of the community!

Bullwinkle