A new alloy, titanium 6al 4v, is being used in 3D-printing applications! It is terrific news for 3D printing, as it opens up new possibilities for what can be created using this technology. Made of several elements, including carbon and iron, it is powerful and lightweight. An accidental discovery makes titanium alloy the strongest 3D-printed metal yet!

An alloy of 90% titanium and 10% aluminum was created by a team of researchers from Worcester Polytechnic Institute (WPI) and the University of Connecticut (UConn). The research was published in the journal Science Advances. Titanium is one of the most robust and resilient metals on Earth.

But a new alloy created by combining titanium with aluminum and vanadium atoms is even stronger. The alloy, called Ti-6Al-4V, is made up of aluminum and vanadium atoms in a ratio of 6: 4. It gives it superior strength and resilience compared to other alloys, making it ideal for 3D printing.

3D-printing Titanium 6al 4v

3D-printing Titanium 6al 4v

It gives the alloy an exceptionally high strength-to-weight ratio, making it ideal for use in products where weight is a significant factor. Moreover, the new alloy is also corrosion-resistant, can be used in various environments, and can withstand extreme temperatures and pressures. This combination gives unprecedented alloy strength, making it ideal for high-stress applications. The study was conducted by scientists at MIT and Oak Ridge National Laboratory, and the results were published in Nature Communications.

Best 3d printer for beginners. Flashforge Adventurer 3, which sold 100,000+ units, allows you to get started with 3d printing quickly and effectively.

Titanium 6al 4v

Titanium 6al 4v

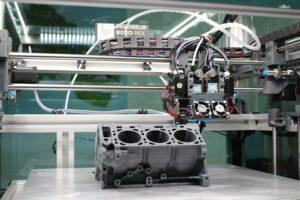

3D printing has been a game-changer for the manufacturing industry, providing a more efficient and cost-effective way to produce parts and products.

The high specific strength of this new alloy makes it ideal for use in aerospace and other applications where weight is a crucial concern. Additionally, the fact that it can be printed using standard 3D printing methods means that the industry could quickly adopt it.

The work on this new alloy is the result of a collaboration between the labs of Hashem Akbari, assistant professor of mechanical and aerospace engineering at NC State.

And Alex Chorus, professor of materials science and engineering and associate dean for research at North Carolina A&T. Alloys are often combinations of metals, such as copper and nickel, with lower melting points than their components.

That makes them easy to melt and cast into solid objects.” Our discovery was an accident,” says Professor Lee. “While the materials we work with are non-toxic, on this occasion, we got a small amount of cadmium from the soldering iron onto the sample’s surface. To our surprise, X-ray diffraction showed that the new alloy formed had one of the highest strength-to-weight ratios of any known material.

“The 3-2-1 multi-scale hybrid nanostructures have shown mechanical properties superior to most metallic alloys,” Liu said. “This can be attributed to the continuous variation of grain sizes and the synergistic effect of the grain sizes.”

The group also performed a secondary high-temperature heat treatment process after the printing, which caused further improvements in strength, toughness, and flexibility. This new alloy was printed using a standard powder bed 3D printing process. It is a crucial breakthrough because Ti-6Al-4V could quickly adopt the alloy in aerospace applications where weight is critical.

(Commonly referred to as Ti-6AL-4V (or Ti 6-4), this designation refers to its chemical composition of almost 90% titanium, 6% aluminum, 4% vanadium, 0.25% (max) iron and 0.2% (max) oxygen. It features excellent strength, low modulus of elasticity, high corrosion resistance, good weldability, and heat treatable.)

The ability to use standard 3D printing methods also enables manufacturers to develop customized components using this new material. Now that they have proven the ability to 3D print this alloy, they will work towards improving its properties to make it even stronger.

3D-printing Titanium 6al 4v Tinsel Strength

3D-printing Titanium 6al 4v Tinsel Strength

And now, a new 3D-printed metal boasts the highest specific strength of any metal: titanium. Researchers at MIT and Northeastern University developed this new titanium alloy, and it has the potential to revolutionize the way we create substantial yet lightweight parts for everything from airplanes to automobiles.

The high specific strength of this new alloy makes it ideal for use in aerospace and other applications where weight is a crucial concern. Additionally, the fact that it can be printed using standard 3D printing methods means that the industry could quickly adopt it.

The alloy, known as Ti-6Al-4V, comprises 90 percent titanium and 10 percent aluminum. The remaining 4 percent includes small amounts of vanadium and iron. This new alloy was developed by a team led by Dr. Michael Kessler at the University of Delaware’s Center for Functional Nanomaterials (CFN). The team used a process called directed energy deposition (DED) to create the alloy.

Ti-6Al-4V is fabricated using a 3D printing process known as selective laser melting. In tests, the alloy exhibited an ultimate tensile strength of 1,640 MPa (megapascals) and specific strength (strength-to-weight ratio) of 496 MPa•m/kg—the highest values ever reported for any 3D printed metal.

Conclusion,

New manufacturing methods are in the works for more substantial and lighter metals. “We can take advantage of 3D printing to achieve designs that are impossible with traditional manufacturing technologies, but until now, this has only been possible with plastic or wax-based materials. The ability to print stainless steel will open up new possibilities in aerospace, automotive, electrical, and many other industries,” said Professor Kasia Smulewicz of the Brown School.

3D printing is creating an object with a printer that uses additive manufacturing. The process covers Manual and automatic methods, using a wide range of materials, including plastics, metals, foodstuffs, and other substances. 3D printing is used in architectural design, engineering, and mechanical engineering fields.

Can You Help?

We don’t want to offend you, but we’re reaching out and asking for your help in leaving us a comment. It’s easy to do and only takes a few minutes. We appreciate your feedback and want to ensure your voice is heard. Thank you!

We only ask for reviews from all customers to improve our services.

Don’t you agree that reading reviews of a business’s services or products helps you make an informed decision?

Bullwinkle