3D printers for dental professionals FlashForge USA to launch new open-material Hunter S System 3D printing for dentistry is one of the most powerful innovations to come along in a long time. It offers a cheaper alternative for custom dental appliances and allows you to use 3D data of your dental patient’s mouth to create an accurate digital impression before any treatment begins.

3D printers for dental professionals FlashForge USA to launch new open-material Hunter S System 3D printing for dentistry is one of the most powerful innovations to come along in a long time. It offers a cheaper alternative for custom dental appliances and allows you to use 3D data of your dental patient’s mouth to create an accurate digital impression before any treatment begins.

3D printing has brought the ability to have an item designed and produced in a digital environment and then manufactured into a real-world product. Many dental companies have found the use of 3D printing beneficial. Here are some examples of how 3D printing is changing dentistry.

to have an item designed and produced in a digital environment and then manufactured into a real-world product. Many dental companies have found the use of 3D printing beneficial. Here are some examples of how 3D printing is changing dentistry.

3D printing is becoming increasingly popular in the field of dentistry. It is no longer reserved for orthodontic cases, and many dental professionals are now utilizing 3D printing to create models, appliances, retainers, and dental restorations. When a replica of a patient’s tooth or teeth is necessary, 3D printing can be used.

Launching The Flashforge Hunter S 3D printer

The Flashforge USA’s Hunter S 3D printer powered by Texas Instruments is a light engine that guarantees high reliability and print quality. The system has a 50,000-hour lifespan, but its linear motion guide actuator ensures sustained LED intensity, thus enabling total print stability and finalizing parts with fine details. Regarding accommodation, the Flashforge Hunter S comes with a 144 x 81 x 150 mm build volume and a durable, easy-to-detach plate that you can remove without needing calibration. Also, the machine’s resin vat is designed to facilitate rapid replenishment, and its FEP vat film is cheap and easy to replace, making both processes quick and painless.

3D Printer for Dental Professionals: FLASHFORGE USA to Launch New Open-Material Hunter S System

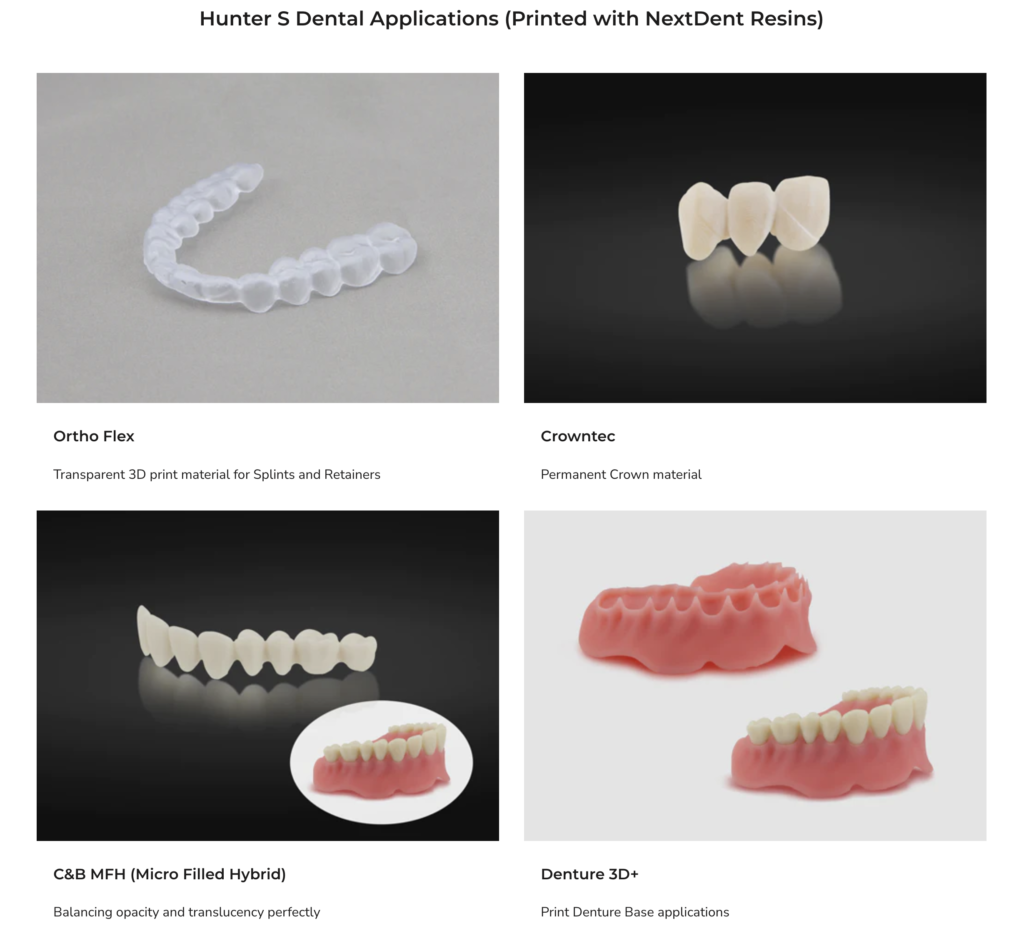

The FLASHFORGE USA Hunter S system is designed for dental professionals who want to use 3D printing technology to create custom-fit dental appliances. This system uses an open-material design, which can accommodate various materials. The benefits of using this system include the ability to create highly detailed models and the flexibility to print in multiple colors.

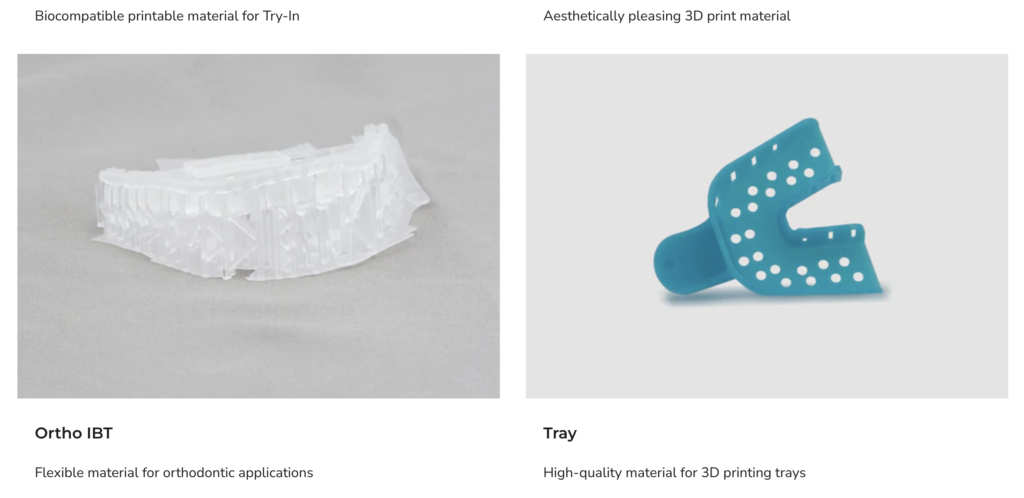

The system’s open-material design means that it can accommodate a variety of different types of materials.

The Flashforge Hunter S system is designed to be compatible with a wide range of materials, making it a versatile option for dental 3D printing. The open-material design means that users can experiment with different types of materials to find the best fit for their needs.

The benefits of using this system include the ability to create highly detailed models and the flexibility to print in multiple colors.

This new system has the potential to revolutionize dental 3D printing. This could allow dentists to create customized braces or implants tailored to each patient’s needs. In addition, printing in multiple colors could make it easier for dentists to quickly identify different types of teeth without relying on x-rays or other imaging methods.

This system is designed for dental professionals who want to use 3D printer technology to create custom-fit dental appliances.

The new FLASHFORGE USA Hunter S system is designed for dental professionals who want to use 3D printing technology to create custom-fit dental appliances. This open-material system uses FDA-approved materials and allows users to print a wide range of dental products, from implants and bridges to dentures and orthodontic devices. With its precision, accuracy, and versatility, the Hunter S is perfect for creating high-quality dental prosthetics that are both comfortable and functional.

Hunter S System Specs.

FlashForge USA

-

- Technology Digital Light Processing (DLP)

- Build Volume 144 x 81 x 150 mm

- Pixel Size X/Y75 μm

- Light Source 405nm LED

- Print Speed 10-30mm/h

- Screen 3.5-inch colorful IPS touchscreen

- Printer Dimension360 x 310 x 565 mm

- Net Weight 17.8 kg

- Connectivity Thumb Drive/USB Cable/Wi-Fi

Conclusion,

Various technological advances disrupt the medical imaging market, including miniaturization and cost-effectiveness. The most notable innovations in dentistry are cone beam computed tomography (CBCT) and intraoral radiography.

It’s worth noting that, for the most part, 3D printing is still in its infancy. But it is getting easier, cheaper, and more common each year. With new products coming on the scene all the time, it’s clear that 3D printing has vast potential for creating customized, useful healthcare devices.”

3D printing is not a replacement for traditional dental manufacturing, but is an excellent addition to the workflow,” said Dr. Nancy Zucker, clinical instructor of the Department of Pediatric Dentistry at the University of Pennsylvania School of Dental Medicine and chair of the Academy’s committee.

“It allows us to perform procedures at a more affordable cost with greater precision and consistency than in the past.” The company also offers a training program for dental professionals.

Dental colleges like Dentalia in France, Harvard University, and others have started using 3D printing technologies to produce hundreds of dental devices, instruments, and even human jaw bones.

The potential for new dental material is highly dependent on the current industry giants like 3M and many other multimillion-dollar companies like those.

The printer houses “the largest print volume available” at 120 x 40 x 130 mm and can print a 5-axis part in a single build. The printer is compatible with an existing SLA resin from 3D Systems and a planned PDMS resin that companies will release in the future.

Can You Help?

We don’t want to insult you, but we’re reaching out and asking for your help in leaving us a comment. It’s easy to do and only takes a few minutes. We appreciate your feedback and want to ensure your voice is heard. Thank you!

We only ask for reviews from all customers to improve our services.

Don’t you agree that reading reviews of a business’s services or products helps you make an informed decision?

Bullwinkle