3D printing technology has come a long way in recent years, and its applications are now virtually limitless. From prototyping to manufacturing, 3D printing is used in countless industries to create everything from medical implants to automotive parts. And the advantages of 3D printing don’t stop there. Here are a few reasons why 3D printing is a versatile and powerful tool.

3D printing technology has come a long way in recent years, and its applications are now virtually limitless. From prototyping to manufacturing, 3D printing is used in countless industries to create everything from medical implants to automotive parts. And the advantages of 3D printing don’t stop there. Here are a few reasons why 3D printing is a versatile and powerful tool.

3D printing is making three-dimensional solid objects from a digital file.

The creation of a 3D-printed object is achieved using additive processes. An additive process creates an object by successively adding material layer by layer. 3D printing is the opposite of subtractive manufacturing, the traditional manufacturing approach where excess material is removed from a piece of stock. 3D printing technology has come a long way in recent years and shows no signs of slowing down.

Applications for 3D printing are now virtually limitless, from prototyping to manufacturing.

3D printing is a rapidly evolving technology that has the potential to revolutionize manufacturing. With 3D printing, businesses can create prototypes and finished products quickly and easily without the need for expensive tooling or molds. This flexibility opens up new possibilities for product design and customization. Additionally, 3D printing can create parts and products that would be impossible to manufacture using traditional methods. As technology continues to improve, the applications for 3D printing are becoming virtually limitless.

Benefits of 3D printing include:

3D printing has a lot of advantages over traditional manufacturing methods. One advantage is that it’s much more affordable to set up a 3D printing operation than it is to set up a traditional manufacturing facility. Additionally, 3D printing enables businesses to quickly and easily prototype new products without incurring the high costs associated with setting up and running a manufacturing plant. Finally, 3D-printed products can be customized much more easily than traditional ones. Businesses can produce unique items better suited to their customers’ needs.

3D printing has a lot of advantages over traditional manufacturing methods. One advantage is that it’s much more affordable to set up a 3D printing operation than it is to set up a traditional manufacturing facility. Additionally, 3D printing enables businesses to quickly and easily prototype new products without incurring the high costs associated with setting up and running a manufacturing plant. Finally, 3D-printed products can be customized much more easily than traditional ones. Businesses can produce unique items better suited to their customers’ needs.

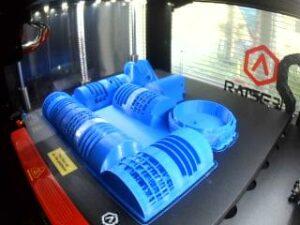

-Ability to create complex shapes and structures

3D printing is making three-dimensional solid objects from a digital file. The creation of a 3D-printed object is achieved using additive processes. In an additive process, an object is created by successively adding material layer by layer. 3D printing is the opposite of subtractive manufacturing, the traditional approach to manufacturing where excess material is removed from a piece of stock. Many manufacturers are turning to 3D printing to create complex shapes and structures that would otherwise be impossible with traditional manufacturing methods.

3D printing is making three-dimensional solid objects from a digital file. The creation of a 3D-printed object is achieved using additive processes. In an additive process, an object is created by successively adding material layer by layer. 3D printing is the opposite of subtractive manufacturing, the traditional approach to manufacturing where excess material is removed from a piece of stock. Many manufacturers are turning to 3D printing to create complex shapes and structures that would otherwise be impossible with traditional manufacturing methods.

-Flexibility in design

3D printing offers many advantages over traditional manufacturing methods, including more flexibility in design. With 3D printing, you can create complex shapes and detailed designs that would be difficult or impossible to produce with traditional manufacturing methods. This flexibility makes 3D printing ideal for prototyping and short-run production. In addition, 3D-printed parts are often stronger than those made with conventional methods because the layers bonding them together are less likely to fracture under stress.

3D printing offers many advantages over traditional manufacturing methods, including more flexibility in design. With 3D printing, you can create complex shapes and detailed designs that would be difficult or impossible to produce with traditional manufacturing methods. This flexibility makes 3D printing ideal for prototyping and short-run production. In addition, 3D-printed parts are often stronger than those made with conventional methods because the layers bonding them together are less likely to fracture under stress.

-Increased speed and efficiency

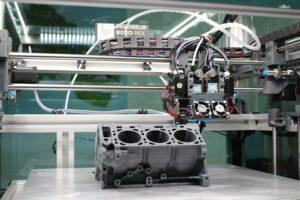

The future of 3D printing lies in its ability to speed up and streamline the manufacturing process. With this technology, manufacturers can create objects faster and with less waste. The benefits of 3D printing are evident when considering its potential applications in various industries. In healthcare, for example, 3D-printed prosthetics and implants offer patients customized treatments that are often more comfortable and effective than traditional options. In the automotive sector, engineers use 3D printers to create lighter and stronger parts than conventional ones.

The future of 3D printing lies in its ability to speed up and streamline the manufacturing process. With this technology, manufacturers can create objects faster and with less waste. The benefits of 3D printing are evident when considering its potential applications in various industries. In healthcare, for example, 3D-printed prosthetics and implants offer patients customized treatments that are often more comfortable and effective than traditional options. In the automotive sector, engineers use 3D printers to create lighter and stronger parts than conventional ones.

This site is owned and managed by 3D Printing by Kevin, a participant in the Affiliate Associate Programs, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Affiliate programs.

Thanks,

Bullwinkle

I 100% agree that 3D printing is absolutely epic! I remember being in summer camps as a kid and playing around with 3D printing before. It was super cool to make various custom toys. I haven’t been in touch with 3D printing for a long time, though. Are we able to use more materials outside of plastic to print stuff? I remember thinking about wanting that as a kid.

Hello Kevin, The printer filaments have matched the imagination! 3d printing technology has grown by leaps and bounds and will continue.

The topic is fascinating, but unfortunately, I don’t know much. So finding a website focusing on it’s a valuable resource for all the people with no experience, as I am who will approach it. So many people want to be educated about this topic, and if you are focused on that will be priceless. Great Idea!

Hello, thanks for stopping by!