Here are a few ways to solve the “not extruding” at the beginning of the model. It can happen with 3D printers, and it causes some major headaches for 3D printing enthusiasts and newbies who are new to this area. I have compiled all these solutions in this article to make it easy for you to solve this problem.

Here are a few ways to solve the “not extruding” at the beginning of the model. It can happen with 3D printers, and it causes some major headaches for 3D printing enthusiasts and newbies who are new to this area. I have compiled all these solutions in this article to make it easy for you to solve this problem.

One possible cause of the Not Extruding at the Start of Print issue is an incorrect nozzle temperature.

If the nozzle is too cold, the filament may not be able to flow smoothly through the nozzle. On the other hand, if the nozzle is too hot, the filament may become too soft and deform, leading to poor print quality. To fix this issue, try adjusting the nozzle temperature to the recommended setting for the filament you are using. You can find this information on the filament manufacturer’s website or by consulting a knowledgeable 3d Printer expert.

Another common cause of the Not Extruding at the Start of Print issue is an incorrect extrusion rate.

This can happen if the extruder is not feeding the filament into the nozzle at the correct speed. Try adjusting the extrusion rate in your 3D Printing software to fix this issue. You may also need to check for any blockages in the filament path, such as a clogged nozzle or kinked filament.

Are you unable to get a successful extrusion at the start of your print?

A number of issues could cause it, so here are some additional troubleshooting tips. Firstly, ensure that you are running the latest version of Cura, as past problems with E3D V6 were solved in newer versions of Cura. Secondly, inspect your filament carefully and make sure it is free from knots or irregularities.

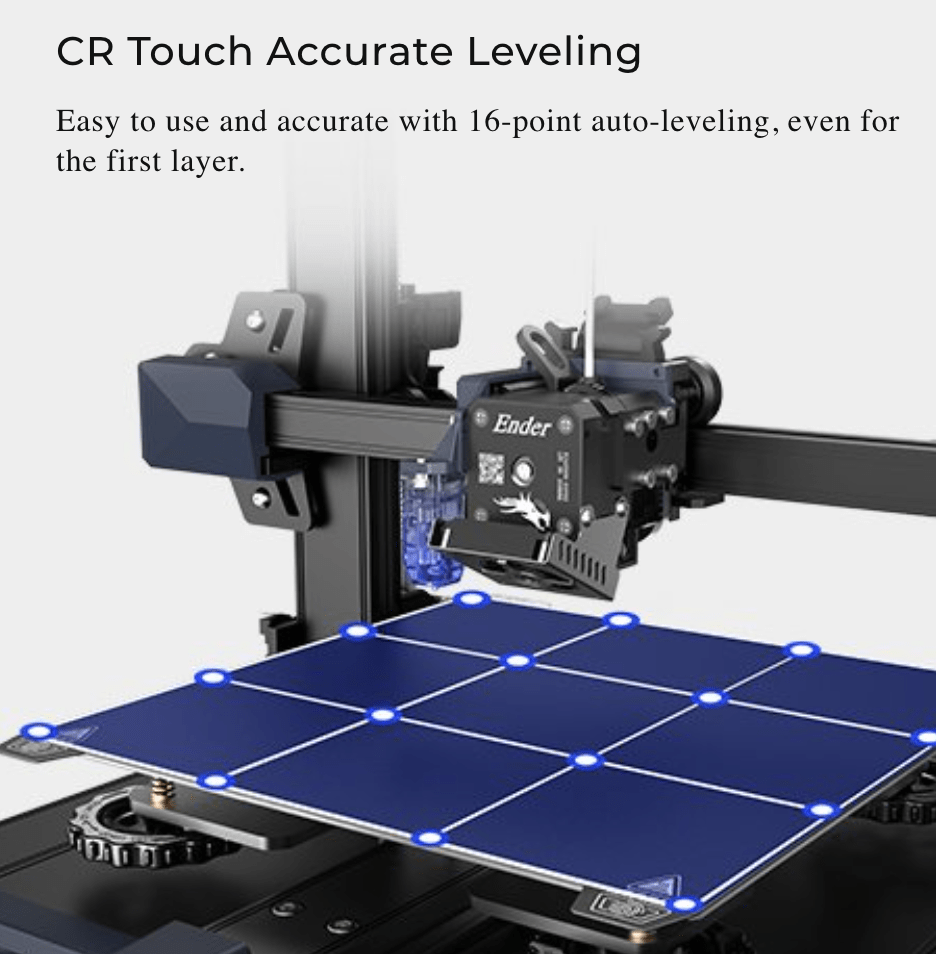

An uneven bed level,

It’s one of the most common causes for a 3D printer not to extrude filament at the start of a print. To rectify this issue, it may be necessary to make adjustments to the filament nozzle and build plate distance, incorporate shims or other leveling tools, and clear away any debris obstructing its ability to push through. Another solution worth considering is re-calibrating the extruder or replacing it altogether.

Regardless of the 3D-printed object you’re constructing,

it is paramount to understand bed leveling prior to beginning a print. This process is especially crucial when considering the initial layer of your project; this layer tends to be the first few millimeters and dictates how successful a print will be. Variables such as temperature, levels on the bed, and even filament stickiness can determine how well this critical layer turns out. Understanding bed leveling is essential to ensure minimal issues with deformation or fracture for long-term longevity in your projects.

Incorrect filament diameter

Incorrect filament diameter

The 3D filament is made from ABS plastics. Not all filaments are the same; some can jam up your nozzle.

For a 3D printing enthusiast, achieving perfect prints can take time and effort. Making sure your slicer knows the filament diameter is critical, as it allows accurate pressure to be used for effective extrusion. TPE has been known to replace ABS for its valuable properties; however, setting the wrong extrusion width and speed could damage any 3D printing project. It’s essential to confirm these settings are just right, so you don’t have any problems with your prints.

To prevent this issue from occurring, it is essential to store your filament and keep it away from moisture properly. Exposure to moisture can cause the filament to absorb water, which can cause changes in the diameter and lead to extrusion issues. It is also a good idea to periodically check the diameter of your filament to ensure it has stayed the same.

If you still have issues with the incorrect filament diameter, it is a good idea to try a different filament spool to see if that resolves the problem. There may also be an issue with the extruder itself, in which case it may be necessary to clean or replace it.

The wrong-size extruder nozzle

If the nozzle size is too small, the filament may not be able to flow through it properly. Conversely, if the nozzle size is too large, the filament may not be able to flow at the correct rate.

The leading cause is using a nozzle that is too small for the filament being used. When your extruder is pulling in filament, its diameter should be close to the ID (inside diameter) of the nozzle. Using a filament size larger than what your printer was designed for can also cause problems. While some workarounds are available, such as adjusting the backlash settings on your X-carriage, it’s always better to use an appropriately sized nozzle.

Most 3D printing problems have simple solutions; we initially thought this article would be much longer and more complicated.

Debris or clogs can prevent the filament from flowing correctly, leading to a host of issues that typically arise when you’re printing. Unclog the nozzle and remove any obstructions in your printer’s feed mechanism to fix this issue.

Depending on the type of 3D printer you have, there are several components that may need to be calibrated or cleaned. In order to determine what needs to be fixed, have the technical specifications for your printer handy, so you know what’s possible and which parts might need adjustments.

Don’t let a bad batch of filament get in the way of your success or slow you down. With some careful troubleshooting and advice from online experts, you can fix issues with 3D printing materials like PVA and ensure that your prints are as successful as possible.

In conclusion,

troubleshooting issues with your 3D printer not extruding at the start of a print can be frustrating. Still, with the right approach and understanding of the potential causes, it is possible to identify and fix the problem. The most common reasons for this issue include incorrect bed leveling, temperature, nozzle size, filament diameter, and more.

Now that you have this information, what do you think about it? Leave your comment below!

By following the tips outlined in this guide, you can troubleshoot and resolve issues with 3D printing. User-friendly designs are paramount to a successful print: avoid over-complicated designs and find strategies for designing complex models. Remember to take your time and be patient.

Thanks,

Bullwinkle