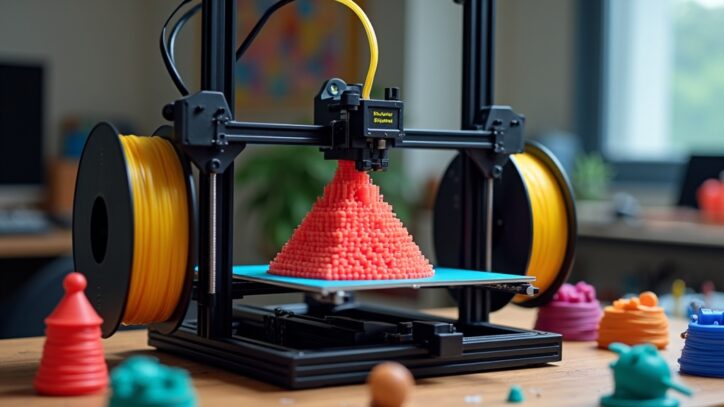

3D printing is one of the most transformative technologies of our time. It takes a digital model and turns it into a physical object by building it one ultra-thin layer at a time. If you’ve never seen a 3D printer before, imagine a regular paper printer—except instead of ink on paper, it creates real-world objects in virtually any shape you can imagine.

At its core, 3D printing requires only two things:

- A digital 3D file — the blueprint for your object

- A 3D printer — the machine that brings that blueprint to life

The digital file tells the printer exactly how to create the model—layer by layer, shape by shape, detail by detail. Once the file is ready, the printer melts material (usually plastic) and deposits it in thin lines until the entire object is complete.

How 3D Printing Actually Works (Simple Explanation)

Most consumer 3D printers today use a process called Fused Deposition Modeling (FDM). This method is popular because it’s affordable, reliable, and beginner-friendly.

Here’s how it works:

- 1. You create or download a digital 3D model. Popular formats: STL, OBJ, 3MF.

- 2. You load the file into a slicer program like Cura, PrusaSlicer, or Bambu Studio. The slicer converts your design into a printable “layer map” called G-code.

- 3. The printer reads the G-code to determine where to move, how fast to move, and how much plastic to extrude.

- 4. The printer heats the filament (PLA, PETG, ABS, etc.) and extrudes it through a nozzle.

- 5. The nozzle draws each layer onto the build plate. As the layers cool, they bond together.

- 6. After hundreds or thousands of layers, your model is complete!

If you’re curious about the printing process in more depth, check out: How Does a 3D Printer Work?

Popular 3D Printing Software for Beginners

You don’t need expensive software to start creating. Modern 3D printing has made it easier than ever to design something amazing with beginner-friendly tools.

- TinkerCAD – Perfect for beginners

- Fusion 360 – Excellent for engineering and precise parts

- Blender – Great for artistic or organic shapes

- SolidWorks / Inventor – Industry-grade CAD tools

If you want a quick head start, here’s a step-by-step guide: How to Make a 3D Model.

Types of 3D Printers (And Which One You Should Choose)

Not all 3D printers are the same. Here are the most common types:

- FDM (Fused Deposition Modeling): Melted plastic filament → best for beginners and functional parts

- SLA (Stereolithography): Cures liquid resin with UV light → high detail, great for miniatures

- SLS (Selective Laser Sintering): Fuses nylon powder → used in professional and industrial settings

- MSLA/DLP: A modern version of SLA using an LCD light panel for fast resin printing

To see a full breakdown of all major printer categories, visit: Different Types of 3D Printers.

How the 3D Printer Builds the Object

Once your file is sliced and ready, the printer performs a mesmerizing ballet of motion, temperature control, and precision.

- The nozzle heats up

- The filament melts

- The printer draws the first layer on the build plate

- Each new layer is added on top of the last

- The object grows upward until complete

Everything is guided by G-code instructions telling the printer:

- Where to move (X, Y, Z)

- How fast to move

- How much material to extrude

- What temperature to maintain

It’s a simple idea—but absolutely magical to watch in real life.

What Materials Do 3D Printers Use?

Most home 3D printers use plastic filament, but the industry has expanded into dozens of material options.

- PLA: Most beginner-friendly; low warping

- PETG: Stronger, more flexible, great for outdoor use

- ABS/ASA: Heat-resistant; used for engineering parts

- TPU: Rubber-like flexible filament

- Nylon: High strength, impact resistant

- Resins (SLA): High-detail, smooth finishes

Want help choosing the right filament? Start here: How to Choose 3D Printing Filaments.

3D Printers Are Incredibly Versatile

Modern 3D printers can create almost anything—from tiny figurines to large, functional parts. Their capabilities scale with your creativity.

Small models? Easy. Large props? Possible. Custom tools, brackets, phone stands, prototypes? Absolutely.

The only real limitation is the printer’s build volume—and even that can be bypassed by splitting large models into multiple pieces.

Conclusion,

3D printing technology has opened the door for anyone to become a creator. Whether you’re an artist, engineer, teacher, hobbyist, or complete beginner, a 3D printer lets you turn ideas into something real—right on your desk.

Have questions? Leave a comment below—your feedback helps us improve every guide we publish.

Some links in this article may be affiliate links. If you make a purchase through them, I may earn a small commission at no extra cost to you. Thank you for supporting the site!

Recommended Guides for New 3D Printing Enthusiasts

How Does a 3D Printer Actually Work?

The Foundations of 3D Printing

Different Types of 3D Printers

How to Choose the Right Filament