3D printing is the new manufacturing world, from consumer interests to medical contraptions. But what about building? Could this technology change the way buildings are made? For most of history, construction meant an array of materials had to be manually assembled. But 3D printing makes it possible to build entire buildings out of concrete, brick, and other materials.

The firm WinSun believes it can.

The company prints houses—single-family, suburban-style homes—in China. The firm reported earlier this year that it has printed 10,000 of them and plans to print 1,000 more by the end of the year. The firm’s process begins with a concrete mixture and reinforces it with fiberglass for strength. The mixture is poured into a large printer and slowly solidifies.

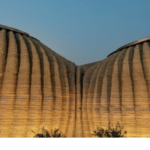

Monolite’s Experimental Concrete 3D Printer

Spanish company Monolite believes 3D printing could change the way we make buildings. The company is developing a technique to print a unique concrete mix which it then uses to print walls, staircases, and furniture. However, a few companies are beginning to experiment, and we have seen some impressive results.

French company Construction Cellular

It has used a process that they call Cellular Architecture. The company has printed 22 3D printed homes in less than a year. The technology allows them to build homes that are extremely energy efficient and can be produced quickly.

The UK has developed a novel type of 3D printing that uses liquid concrete rather than plastic.

The technology could cut down on construction waste and help reduce carbon emissions by making it easier to reuse materials. Unlike conventional 3D printing, which produces a solid object, this type of technology, called concrete extrusion, works like an industrial-sized pasta machine.

Liquid concrete has been heralded as a game-changer For 3D printing due to its sustainability and strength. The UK is set to make this technology even more accessible and sustainable, with promises of cheaper, quicker construction times and less waste.

Liquid concrete is a sustainable and robust 3D printing material.

Now researchers in the UK have developed a novel type of 3D printing that uses liquid concrete rather than plastic. The technology could cut down on construction waste and help reduce carbon emissions by making it easier to reuse materials.

Unlike conventional 3D printing, which produces a solid object, this type of technology, called concrete extrusion, works like an industrial-sized pasta machine. It can create hollow objects with walls as thick or thin as desired.

Unlike conventional 3D printing, which produces a solid object, this type of technology, called concrete extrusion, works like an industrial-sized pasta machine. It can create hollow objects with walls as thick or thin as desired.

New research from the UK promises cheaper, quicker construction times and less waste with liquid concrete 3D printing technology.

A new type of 3D printing that uses liquid concrete rather than plastic has the potential to revolutionize construction. The concrete extrusion technology works like an industrial-sized pasta machine and could cut down on construction waste and help reduce carbon emissions by making it easier to reuse materials.

According to the National Institute of Standards and Technology, construction and demolition waste accounts for approximately 30 percent of the total solid waste in the United States. It is a significant waste, and it’s only getting worse as our population continues to grow.

What could relief be in sight through 3D printing? The US Green Building Council (USGBC) Construction & Demolition Waste Challenge calls for the ‘Next Big Idea in Construction.’ The challenge encourages designers, researchers, and entrepreneurs to develop technologies, materials, and processes that can help reduce construction waste. The contest is open to any individual or company that can pitch a new idea that reduces waste by 30 percent (from its current state).

So what is being done about it? In his book, The Earth Moved, Geoff Manaugh discusses a new wave of materials science research that could change how we think about waste. In the book, he writes: “As the total quantity of waste continues to grow unabated, the cost of dealing with it must also continue to grow, presenting us with an intractable problem of proportions that bear little relation to our actions.

The US alone produces 2.5 billion tons of construction and demolition waste every year, and that trend is increasing annually. In the United States, only about a third of construction waste is recycled or reused. That alone is a massive waste of potentially useful material. A new project out of Harvard University may change all that by creating an unknown 3D printer capable of recycling concrete into usable building materials. Now, a new 3D printing technology could solve that problem.

New 3D Printing Technology Could Help Reduce Construction Waste.

The technology uses concrete as its primary ingredient and can 3D print structures in hours. The process begins when the concrete is air laid at the job site by a machine similar to a large dump truck. A specialized nozzle then spreads a fiber mesh over the layers of concrete, causing the material to cure faster due to a denser structure.

Fortunately, there is a solution to this problem, and it involves new 3D printing technology. Researchers at the Illinois Institute of Technology (IIT) have developed a new type of 3D printer that can 3D print buildings, some of which are made from 100 percent waste byproducts. These 3D-printed buildings can also help reduce the construction waste generated in the building process.

We would love to know what you think. Please do us a favor and comment if you have a moment. It enables us to improve upon everything we do.

We’ve made leaving a comment or question easy! Just go below.

Some of the links in this article are affiliate links. If you were to buy something after clicking on one of these links, I would get a small commission.

Thanks for being part of the community!

Bullwinkle