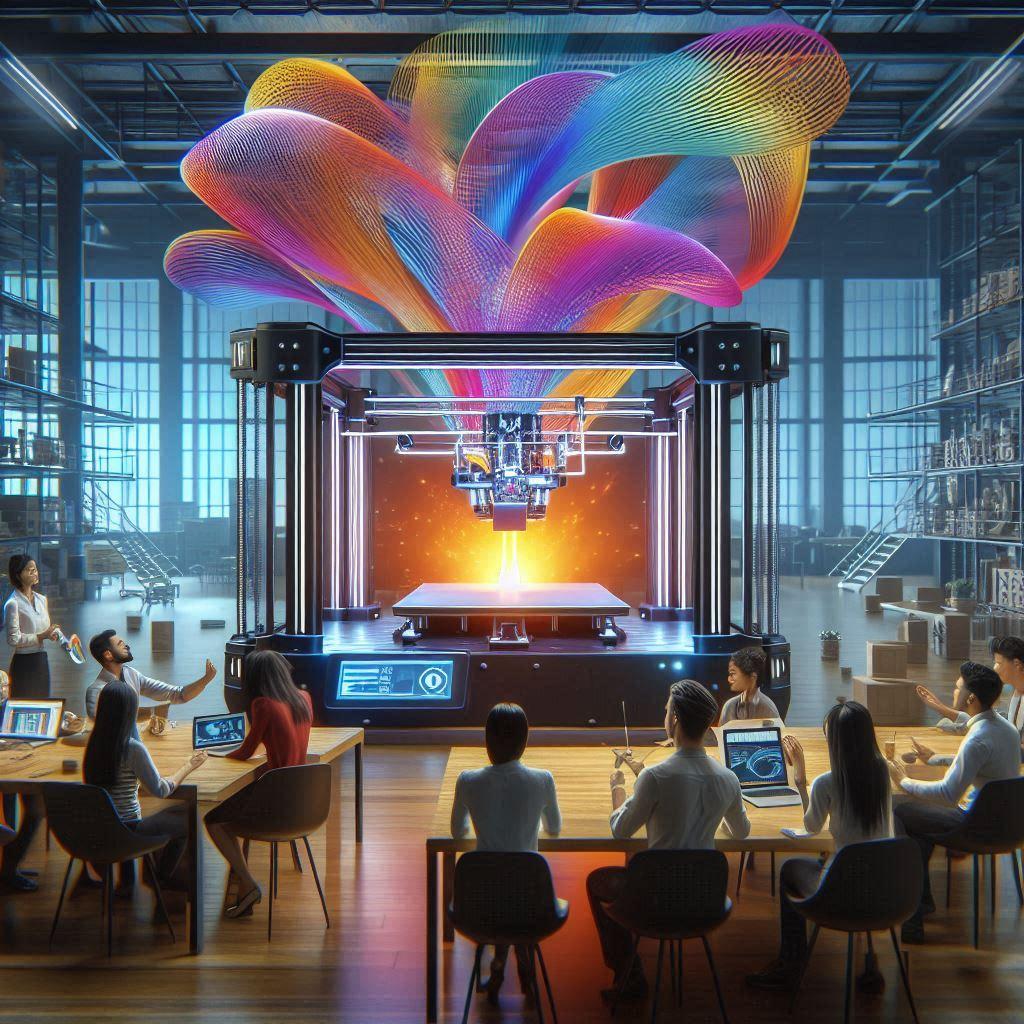

The landscape of additive manufacturing is shifting from manual CAD mastery to AI-assisted generation. For enthusiasts focusing on 3D prints that require both aesthetic precision and functional integrity, the integration of artificial intelligence into the STL workflow is no longer a futuristic concept—it is a current necessity for efficiency.

Whether you are mastering 3D printing for beginners or optimizing a professional lab, understanding how AI bridges the gap between a prompt and a physical object is essential.

AI vs. Traditional STL Workflows

The traditional workflow requires hundreds of hours of learning parametric design or mesh modeling. AI-generated workflows utilize neural networks to interpret geometric requirements, often bypassing the steepest parts of the learning curve.

Comparison: Manual CAD vs. AI Generation

| Feature | Traditional CAD (Fusion 360/Blender) | AI-Generated STL Workflows |

| Learning Curve | High (Months to Years) | Low (Days to Weeks) |

| Design Speed | Hours/Days | Minutes |

| Complexity | Limited by user skill | High (Generative Topology) |

| Accuracy | Absolute / Exact | Iterative / Approximate |

| Best For | Engineering & Mechanical Parts | Organic Shapes & Rapid Iteration |

Technical Deep-Dive: Top 3D AI-to-STL Platforms for 2026

As of early 2026, the market has consolidated into three clear leaders, each serving a distinct niche in the 3D printing ecosystem. Selecting the right tool depends on whether you value structural accuracy or artistic detail.

1. Meshy AI: Best for Artistic & Organic Details

Meshy has established itself as the go-to for character designers and prop makers. Its “Sculpting-level” models provide the high-fidelity textures and organic curves that are notoriously difficult to model in traditional CAD.

- Key Feature: Text-to-PBR (Physically Based Rendering) which translates directly into high-detail surface textures on 3D prints.

- Best For: Figurines, cosplay props, and decorative art.

- Workflow: Best paired with 3D printing calibration tests to ensure “AI bumps” (minor surface noise) are smoothed by your slicer settings.

2. Tripo AI: The Speed and Repair Champion

Tripo AI excels in the “closed-loop” workflow. It is not just a generator; it includes built-in AI auto-repair tools specifically designed to fix non-manifold geometry before you export your STL.

- Key Feature: AI-powered mesh cleanup and “Water-tight” verification.

- Best For: Rapid prototyping where you need a manifold (printable) file on the first try.

- Performance: Capable of generating printable base meshes in under 60 seconds.

3. Hunyuan 3.0: The Precision & Geometry Specialist

For users focused on structural integrity over aesthetics, Hunyuan 3.0 is the current industry leader. It prioritizes geometric accuracy, making it the most “engineering-adjacent” AI tool available for 3D printing for beginners.

- Key Feature: High-fidelity reconstruction from single or multi-view images.

- Best For: Functional parts, replacement components, and objects requiring exact silhouettes.

- Integration: Produces a cleaner quad-based topology that is easier to modify in software like Blender.

Technical Foundations for Success

To achieve high-quality results from AI-generated models, your hardware must be capable of translating complex geometries into physical reality.

Essential Hardware and Materials

- Precision Scanners: For those bridging the physical-to-digital gap, the 3DMakerpro Global line offers industrial-grade accuracy for capturing real-world objects to use as AI reference.

- Reliable Printers: Machines like the Creality K1 series or Ender-3 V3, available via Creality, provide the stability needed for intricate generative designs.

- Quality Filament: AI designs often feature thin walls. Using premium COEX Filament ensures consistent melt flow and structural bond.

3D Printing Calibration for AI Geometries

AI-generated STLs often feature hyper-organic structures that can challenge standard slicer settings. Proper 3D printing calibration is the difference between a successful print and a failure.

- Flow Rate Calibration: Essential for the intricate lattice structures common in generative design.

- Retraction Tuning: AI models often involve high-frequency travel moves; proper retraction prevents stringing.

- Flat-Base Verification: Many AI models lack a perfectly flat bottom. Use your slicer’s “Cut” tool to ensure a solid first-layer footprint.

Expert Tip: When printing AI-generated files, use a high-quality filament from trusted sources like COEX to reduce the risk of mid-print clogs during complex retractions.

Frequently Asked Questions

How do I turn a 2D image into a 3D printable STL using AI?

Modern AI tools like Tripo or Meshy use diffusion models to estimate depth maps and generate a point cloud, which is then converted into a mesh STL. Tools from HONG KONG CHAORONG CO. also support specialized hardware to assist this process.

Can AI-generated STLs be used for functional engineering?

Yes, but they require oversight. While AI excels at organic shapes, generative design tools are now being used to optimize load-bearing structures that are lighter and stronger than traditional designs.

Is AI-generated 3D modeling beginner-friendly?

Absolutely. It lowers the entry barrier for 3D printing for beginners by allowing users to describe what they want rather than drawing it.

Elevating Your Setup

Transitioning to an AI-driven workflow requires a robust ecosystem. To explore the latest in high-speed printing and scanning technology, visit our vetted partners:

- Creality: Industry-standard printers for every budget. View Deals

- 3DMakerpro: Professional 3D scanning solutions. Explore Scanners

- COEX: American-made filament for high-performance prints. Shop COEX

- HONG KONG CHAORONG CO.: Specialized 3D peripherals and components. Learn More

Internal Resources for Growth

- Check out our Ultimate 3D Printing Calibration Guide to prep your machine.

- New to the hobby? Read our 3D Printing for Beginners roadmap.

US Store-New Product Launch: SPARKX i7