3D Printer-Equipped Truck Beds

In an era where innovation is the key to staying ahead, Ford Motor Company has once again demonstrated its commitment to leading the automotive industry into the future.

The American auto giant has unveiled a groundbreaking addition to its manufacturing arsenal: 3D printer-equipped truck beds.

This move not only signifies a leap in manufacturing efficiency but also showcases Ford’s dedication to embracing cutting-edge technology.

Revolutionizing Auto Manufacturing

The integration of 3D printers into Ford’s truck beds is a game-changer for the automotive industry.

This technology allows for on-the-spot manufacturing of parts and components, significantly reducing the time and cost associated with traditional manufacturing methods.

The flexibility offered by 3D printing means Ford can produce parts on demand, eliminating the need for large inventories and streamlining the supply chain.

Customization at Its Core

One of the most exciting aspects of this innovation is the potential for customization.

Ford customers can now look forward to a level of personalization previously unattainable in mass-produced vehicles.

Whether it’s a unique accessory, a specific tool for a truck bed, or a custom-designed part, the possibilities are endless.

This not only enhances the customer experience but also opens up new markets for Ford.

Sustainability and Efficiency

Ford’s move towards 3D printing technology is also a step forward in sustainability. By producing parts only as needed, there is a significant reduction in material waste.

Additionally, the ability to recycle materials used in 3D printing further underscores Ford’s commitment to environmentally friendly practices.

This approach not only benefits the planet but also aligns with the growing consumer demand for sustainable products.

The Future of Auto Manufacturing

The introduction of 3D printer-equipped truck beds is just the beginning.

Ford’s innovation paved the way for more advanced manufacturing techniques in the automotive industry. It sets a new standard for efficiency, customization, and sustainability.

As other manufacturers follow suit, we can expect to see a transformation in how vehicles are designed, produced, and delivered.

Conclusion

Ford’s latest innovation is a testament to the company’s forward-thinking vision.

By harnessing the power of 3D printing technology, Ford is not just revolutionizing its manufacturing process but is also redefining what is possible in the automotive industry.

As we move forward, it will be exciting to see how this technology evolves and how it continues to shape the future of auto manufacturing.

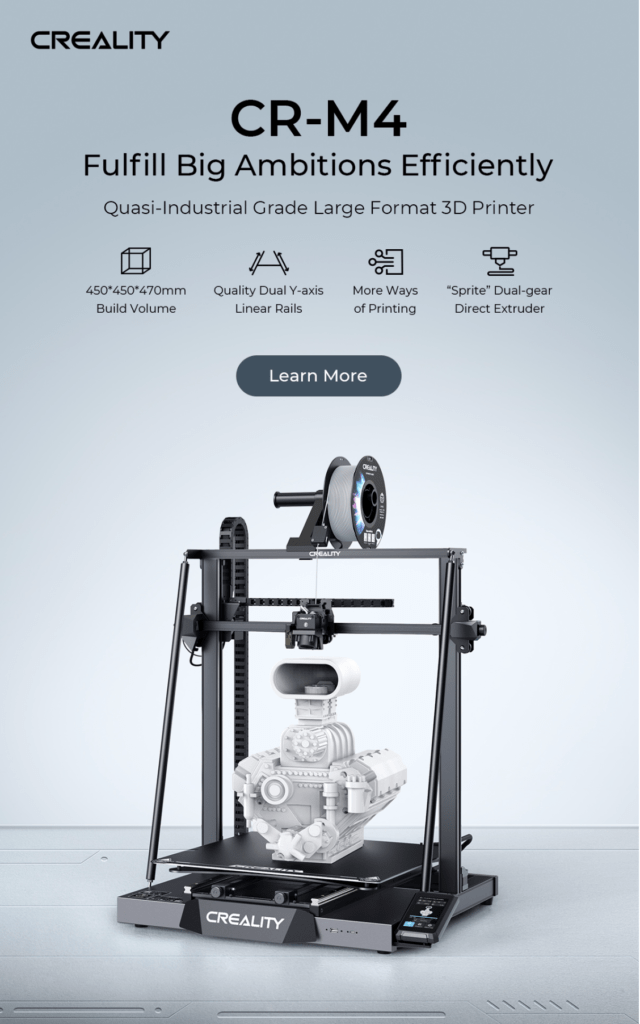

The Creality CR-M4, a state-of-the-art 3D printer, stands as an exemplary choice for Ford’s innovative integration of 3D printing technology into their truck beds.

Here’s a detailed look at why the CR-M4 is ideally suited for this groundbreaking venture:

High Precision and Reliability

The Creality CR-M4 is renowned for its high precision and reliability in printing. This is crucial for automotive applications where every part needs to meet stringent quality and safety standards.

Ford’s use of the CR-M4 ensures that each component produced is of the highest quality, consistent with the company’s reputation for durability and reliability.

CR-M4 3D Printer – $934.00

Retail Price: $1,099.00

You Save: $165.00

from: CrealityOfficialStore

Large Build Volume

One of the standout features of the CR-M4 is its large build volume.

This is particularly beneficial for Ford, as it allows the production of a wide range of parts, from small custom fittings to larger components.

The versatility offered by this large build volume aligns perfectly with Ford’s need for producing diverse parts on demand.

Speed and Efficiency

The CR-M4 operates with impressive speed without compromising on quality.

In the fast-paced automotive industry, where time is of the essence, this efficiency is invaluable.

Ford can benefit from reduced production times, leading to faster turnaround times for vehicle manufacturing and repairs.

Material Compatibility

Ford’s commitment to sustainability is supported by the CR-M4’s compatibility with a variety of materials, including eco-friendly options.

This aligns with Ford’s goal of reducing waste and promoting sustainable manufacturing practices.

User-Friendly Interface

The Creality CR-M4 is designed with a user-friendly interface, making it accessible to operators of varying skill levels.

This ease of use is essential in a busy manufacturing setting like Ford’s, where quick adaptation and seamless integration into existing processes are necessary.

Durability and Low Maintenance

Given the demanding environment of automotive manufacturing, the durability and low maintenance requirements of the CR-M4 are significant advantages.

Ford can rely on the printer’s consistent performance over time, which is critical for maintaining production schedules and reducing downtime.

Scalability

As Ford looks to the future, the scalability offered by the CR-M4 is a key benefit.

Whether scaling up for larger production runs or adapting to new manufacturing challenges, the CR-M4 provides the flexibility Ford needs to stay ahead in a competitive market.

Conclusion,

The Creality CR-M4’s combination of precision, versatility, speed, and sustainability makes it an excellent choice for Ford’s innovative venture into 3D printer-equipped truck beds.

This technology not only aligns with Ford’s manufacturing needs but also supports its goals of efficiency, customization, and environmental responsibility.

As Ford continues to lead the way in automotive innovation, the CR-M4 stands as a valuable tool in its manufacturing arsenal.

Thanks,

Bullwinkle