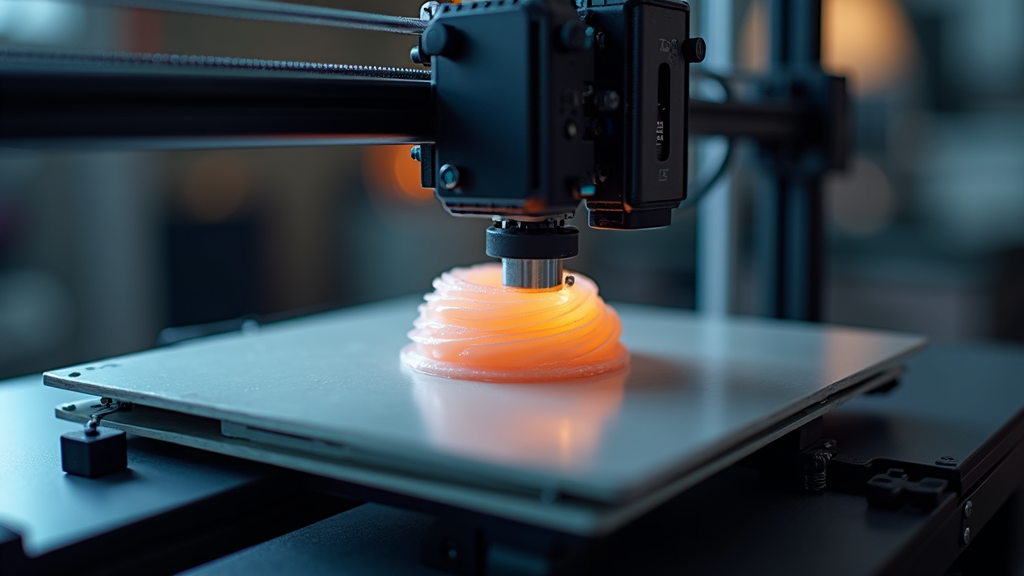

Make 3D printed vases watertight with the exact slicer settings I use, plus material choices, troubleshooting, and a comparison table of filament, printers, and scanners.

Watertight 3D Prints: The Exact Settings I Use for Leak-Proof Vases

Can 3D printed vases actually hold water without leaking?

Yes, as long as you print with settings that reduce internal gaps and improve layer fusion. Most “vase mode” leaks come from under-extrusion, thin walls, poor layer bonding, or tiny seam defects. The fix is usually a combination of wall thickness, flow tuning, temperature, and seam strategy, plus a filament choice that behaves predictably.

This pillar page shows the exact baseline settings I use to make vases reliably watertight, plus a troubleshooting checklist and material/printer comparisons you can use to dial in your own setup.

What causes leaks in 3D printed vases?

The common failure points

- Microscopic gaps between extrusion lines (often from low flow, too-cool temps, or printing too fast)

- Thin walls that don’t fully merge into a continuous barrier

- Seam pinholes where starts/stops leave tiny voids

- Poor first-layer seal at the base (especially on textured plates or with imperfect squish)

- Moist filament that pops/foams and creates porous walls

- Inconsistent extrusion from partial clogs, worn nozzles, or poor filament diameter control

If you only change one thing, change this: wall thickness + flow calibration. Those two are the most consistent “leak killers.”

The exact settings I use for leak-proof vases (baseline profile)

These settings are meant to be a practical starting point for most modern FDM printers with a 0.4 mm nozzle. You’ll still want to run a quick flow check because every printer/filament combo is slightly different.

My leak-proof vase baseline (0.4 mm nozzle)

Slicer: Any (Cura/PrusaSlicer/OrcaSlicer compatible concepts)

Mode: Standard print (not vase mode) for best reliability

(You can do vase mode too. I cover that below.)

Geometry and walls

- Walls/Perimeters: 3 (minimum)

- Wall thickness target: ~1.2 mm (with 0.4 mm nozzle, 3 walls is a clean baseline)

- Top layers: 0 (for open vases)

- Bottom layers: 5–8 (more if the base is large)

- Infill: 0% (walls do the work for vases)

Layer and line settings

- Layer height: 0.20 mm (or 0.16 mm for extra surface quality)

- Line width (walls): 0.42–0.48 mm (slightly wider often helps seal)

Temperature, speed, cooling

- Nozzle temp: “High end of normal” for your filament (enough to improve layer fusion without stringing)

- Bed temp: Standard for the filament

- Speed: 35–60 mm/s (slower if your printer struggles with consistent flow)

- Cooling fan: Reduced vs typical PLA profiles (too much cooling can weaken layer bonding)

Flow and seam (the watertight keys)

- Flow/Extrusion multiplier: Start at 100%, then tune

- If you see pinholes or seepage, increase flow slightly in small steps

- Seam position: Aligned/Rear (or “hide seam”)

- Random seams can create lots of micro starts/stops

- Retraction: Conservative (over-retraction can starve the nozzle at restarts)

Base adhesion (stops base leaks)

- First layer: Slightly thicker and slower than normal

- Brim: Optional, but helpful for tall skinny vases to reduce wobble

If you insist on vase mode: my “watertight vase mode” approach

Vase mode can work, but it’s less forgiving because you’re betting everything on one continuous wall. If you want vase mode to hold water:

Vase mode settings that matter most

- Spiralize/vase mode: On

- Wall line count: 1 (forced by mode), so compensate with:

- Wall line width: Increase (within what your printer can reliably extrude)

- Layer height: Moderate (0.2 mm is usually easier to seal than ultra-thin layers)

- Speed: Slower than your normal vase mode speeds

- Temperature: Slightly higher than your standard PLA temp range

- Cooling: Don’t overcool (aim for good bonding)

If your vase is a gift, a planter insert, or anything you truly don’t want to leak: use 3 walls instead of vase mode. It’s simply more reliable.

Quick watertight checklist (print this, then diagnose)

Before printing

- Dry the filament if it pops/crackles

- Clean nozzle / swap to a fresh nozzle if extrusion is inconsistent

- Run a simple flow test cube (or a single-wall calibration)

During printing

- Watch the first layer base: it should look sealed, not “ropey”

- Look for gaps in walls: if you see them, reduce speed or increase flow slightly

After printing

- Fill with water and place on a paper towel for 30–60 minutes

- If it seeps: look at seam line and base first

Leak troubleshooting: symptoms → fixes

“It leaks only at the seam”

- Move seam to the back/aligned

- Slightly increase flow

- Reduce retraction or enable “wipe/coast” carefully (depending on slicer)

- Increase walls from 2 → 3

“It leaks through the wall (not just the seam)”

- Raise nozzle temp slightly (within safe limits for your filament)

- Reduce cooling

- Slow down outer walls

- Increase wall line width slightly

- Dry the filament

“It leaks through the base”

- Add more bottom layers

- Increase first-layer squish slightly

- Slow first layer

- Consider a smoother build surface for a better seal

Best materials for watertight vases (fact-safe comparison)

Different filaments can be watertight. The key is consistent extrusion and good bonding.

Filament comparison for leak-proof vases

| Filament | Watertight potential | Ease of printing | Heat resistance | Notes |

|---|---|---|---|---|

| PLA | High (with tuned settings) | Very easy | Lower | Great for decorative vases; avoid hot water |

| PETG | High | Moderate | Better | Strong bonding; can string; great for functional water-holding |

| ASA/ABS | High | Harder | Higher | Can be excellent if printed well; needs enclosure/warping control |

| TPU | Medium | Moderate | Medium | Flexible prints can seal, but dimensional control varies |

Rule of thumb: For easy, reliable water-holding without special hardware, PETG is often a practical pick. PLA can also work well for room-temperature use if your print quality is solid.

“Do I need a specific printer for watertight prints?”

You don’t need a specific brand, but you do need:

- Consistent extrusion

- Stable temperatures

- Good part cooling control (not necessarily strong cooling, just control)

- A reliable first layer

If you’re shopping for a printer, prioritize extrusion consistency and repeatable calibration over flashy features.

Brand comparison (fact-safe)

This is positioning-focused, not a performance guarantee.

| Brand / Category | Common strengths | Best for |

|---|---|---|

| Creality printers | Wide model variety, big community, lots of upgrade paths | Hobbyists and budget-conscious makers who like tuning |

| Other mainstream FDM brands | Varies by model; often emphasize ease-of-use or reliability | Makers who want fewer tweaks |

If you want to browse Creality options, here’s my affiliate link (disclosed):

Creality via AWIN: https://tidd.ly/3KUghXJ

Disclosure: If you purchase through this link, I may earn a commission at no extra cost to you.

When you should seal a print (and when you shouldn’t)

If you’re holding water long-term (or the vase will sit on wood), sealing can be a smart safety layer. But it’s not always required.

Seal if:

- The vase must hold water continuously (days/weeks)

- You see any seepage during a paper-towel test

- You’re using a tricky filament or very thin walls

You may not need to seal if:

- The print passes a long water test with no dampness

- It’s purely decorative and uses a liner

Note: If the vase will contact potable water, be cautious. Many common sealants and FDM prints aren’t ideal for food-safe use unless you’re using verified food-safe materials and processes.

Turning real objects into vase models (optional workflow)

If you like making vases based on real-world shapes (scans of decor, pottery, or textures), a 3D scanner can speed things up. This is optional, but it’s a fun path for unique designs.

3D scanner comparison (fact-safe)

| Scanner | Typical positioning | Good for |

|---|---|---|

| 3DMakerpro (Global) | Consumer/prosumer scanning tools | Creators scanning objects for art, decor, prototypes |

| Other 3D scanners | Varies widely | Specialized use cases depending on accuracy needs |

3DMakerpro (Global) affiliate link (disclosed):

https://tidd.ly/49ziphJ

Disclosure: If you purchase through this link, I may earn a commission at no extra cost to you.

HONG KONG CHAORONG CO., LIMITED link (disclosed):

https://tidd.ly/4oBR0PW

Disclosure: If you purchase through this link, I may earn a commission at no extra cost to you.

- Flow calibration guide

- Best PETG settings for strong layer bonding

- Fixing under-extrusion and inconsistent lines

- How to dry filament properly

- First layer mastery checklist

FAQ: watertight 3D printing questions (AEO-friendly)

What’s the easiest way to make a 3D printed vase watertight?

Print with three walls, tune flow, use a slightly higher temperature, keep outer walls slower, and reduce cooling enough to improve layer fusion.

Why does my vase leak even though the walls look solid?

Leaks are often from seam pinholes, microgaps, or a porous base caused by imperfect first-layer squish or moisture in the filament.

Is Vase mode watertight?

It can be, but it’s less forgiving because you’re relying on one wall. For reliable watertight results, 3 walls in standard mode is usually easier.

Which filament is best for leak-proof vases?

PLA and PETG can both work. PETG is often chosen for functional water-holding because it tends to bond well and handles warmth better than PLA, but your printer tuning matters more than the label on the spool.

Should I use a sealant?

Only if your print fails a water test or must hold water long-term. Sealing can be a safety backup, not a substitute for good extrusion and bonding.

Final take,

Leak-proof vases come down to continuous plastic with no gaps. If you do three things well, you’ll solve most leaks:

- 3 walls (~1.2 mm)

- Flow tuned for your filament

- Layer bonding optimized (temp, speed, cooling)