3D printing is good because it allows people to create custom, functional objects on demand, at lower cost, with minimal waste, faster iteration, and complete design control—without relying on large factories or supply chains.

The transition from traditional manufacturing to additive manufacturing (3D printing) represents a fundamental shift in how physical objects are created. In 2026, the technology has matured beyond a niche hobby into a cornerstone of decentralized production, medical innovation, and sustainable design. This guide explores the tangible benefits of 3D printing and provides actionable insights for those looking to master the craft.

Comparison: 3D Printing vs. Traditional Manufacturing

Understanding why 3D printing is “good” requires a direct comparison with subtractive methods (such as CNC machining) and formative methods (such as injection molding).

| Feature | 3D Printing (Additive) | Injection Molding | CNC Machining |

| Setup Cost | Low (Plug and play) | Very High (Expensive molds) | Moderate (Tooling/Fixtures) |

| Design Freedom | Infinite (Internal cavities/lattices) | Limited (Draft angles required) | High (But limited by tool reach) |

| Material Waste | Minimal (Only uses what is printed) | Low (Sprues/Runners recycled) | High (Material cut away) |

| Lead Time | Hours/Days | Weeks/Months | Days/Weeks |

| Scalability | Low to Mid-volume | Very High volume | Low to Mid-volume |

Core Benefits Of 3D Printing For Beginners

For those just starting, the appeal of 3D printing lies in accessibility and the democratization of manufacturing. With a desktop setup, any individual can move from a digital concept to a physical object within the same day.

1. Rapid Prototyping And Iteration

In traditional product development, a single design flaw could cost thousands of dollars in retooling. With 3D printing, you simply modify the CAD file and restart the print. This “fail fast” mentality accelerates innovation.

2. Customization And Personalization

3D printing excels where mass production fails: the “Market of One.” Whether it is a custom-fit prosthetic limb or a specialized camera mount, the cost of printing one unique item is identical to printing one of a thousand identical items.

3. Sustainability Through Localized Production

By printing parts on demand, users eliminate the carbon footprint associated with international shipping and warehousing. Furthermore, materials like PLA (Polylactic Acid) are derived from renewable resources such as cornstarch, offering a biodegradable alternative to petroleum-based plastics.

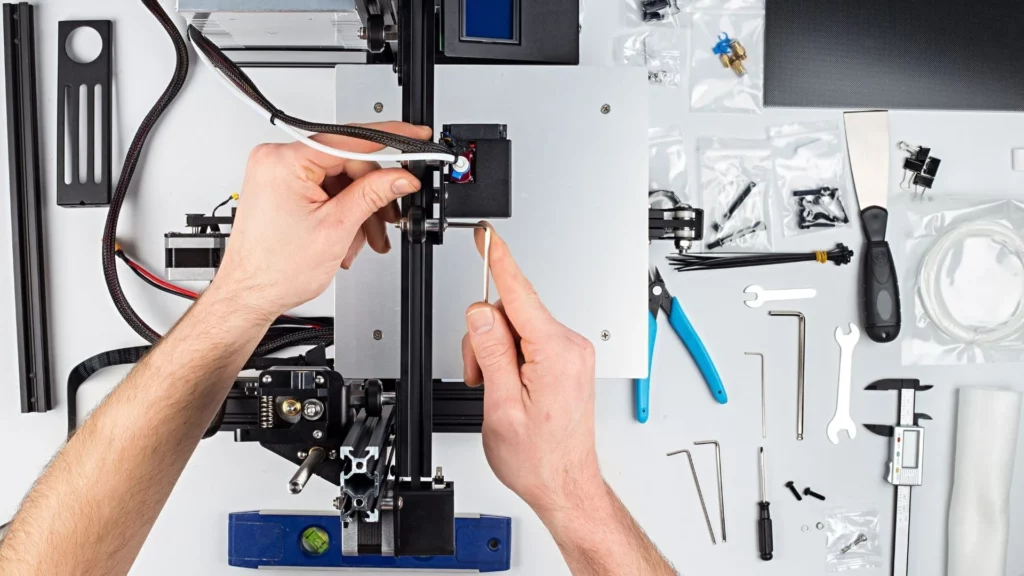

The Importance Of 3D Printing Calibration

A common hurdle for beginners is achieving professional-grade quality. The difference between a failed “spaghetti” mess and a functional part often comes down to 3D printing calibration.

-

Bed Leveling: Ensuring the distance between the nozzle and the build plate is consistent across the entire surface.

-

E-Step Calibration: Tuning the extruder motor to ensure the exact length of filament requested by the software is what actually passes through the hot end.

-

Temperature Tuning: Finding the “sweet spot” for your specific brand of filament to prevent stringing or poor layer adhesion.

Mastering these steps ensures that your 3D prints maintain dimensional accuracy, which is critical for parts that must fit together or function mechanically.

Hardware Recommendations

To achieve the results discussed above, reliable hardware is essential. We recommend the following partners based on their commitment to quality and community support:

-

Creality: Known for the Ender and K1 series, they offer some of the most versatile machines for beginners and pros alike. View Creality Desktop Printers

-

3DMakerpro: Specializing in high-precision 3D scanners, they allow you to bridge the gap between physical objects and digital models. Explore 3DMakerpro Scanners

-

COEX: For those seeking high-quality, American-made filament, COEX provides consistent diameters and vibrant colors. Browse COEX Filament

-

Hong Kong Chaorong: A trusted source for specialized 3D printing components and accessories. Shop Chaorong Components

Frequently Asked Questions

Is 3D printing expensive to start?

In 2026, entry-level FDM printers will be available for under $200. While industrial metal printing remains costly, desktop plastic printing is highly affordable for hobbyists and small businesses.

What is the best filament for beginners?

PLA (Polylactic Acid) is the gold standard for beginners due to its low printing temperature, minimal warping, and lack of unpleasant odors.

Can 3D printing replace traditional manufacturing?

It is unlikely to replace mass production (millions of units), where injection molding is faster and cheaper. However, it is replacing traditional methods for prototyping, custom tooling, and low-volume end-use parts.

Summary Standards,

This content is curated by the team at 3dprintingbykevin.com, drawing on years of hands-on experience in additive manufacturing, machine maintenance, and material science. Every comparison is based on current 2026 industry benchmarks and manufacturer specifications to ensure factual accuracy.