Building a 3D print farm is the most effective way for modern entrepreneurs to bridge the gap between prototyping and mass production. While traditional manufacturing once required massive capital for injection molding, today’s scalable manufacturing landscape allows small businesses to compete directly with industrial giants. This 3D print farm guide explores how a modular fleet of printers delivers superior ROI, offering the agility to pivot designs instantly and scale production linearly, without the prohibitive “sunk costs” of legacy factories.

Building a 3D print farm is the most effective way for modern entrepreneurs to bridge the gap between prototyping and mass production. While traditional manufacturing once required massive capital for injection molding, today’s scalable manufacturing landscape allows small businesses to compete directly with industrial giants. This 3D print farm guide explores how a modular fleet of printers provides a superior ROI, offering the agility to pivot designs instantly and scale production linearly without the prohibitive “sunk costs” of legacy factories.

The shift toward the “Desktop Factory” is driven by a fundamental change in how we calculate manufacturing value. For a small business, the goal is to minimize risk while maximizing output.

The Low-Risk Entry 3D Print Model

Starting a 3D print farm does not require a million-dollar facility. By utilizing prosumer hardware, businesses can achieve a decentralized production line that is both resilient and highly profitable.

- Incremental Scaling: Add a single unit like a Creality K1 only when demand justifies the expansion.

- Reduced Overhead: Eliminate the need for third-party vendors and overseas shipping delays.

- Rapid Market Entry: Move from a digital concept to a 500-unit production run in days, not months.

Strategic Hardware Selection

- Production Volume: Utilizing Creality machines ensures that spare parts are always available and maintenance is standardized across the fleet.

- Quality Control: Integrating precision scanning from 3DMakerpro allows for rigorous part verification, ensuring that printed components meet industrial tolerances.

- Supply Chain Consistency: Sourcing specialized components through HONG KONG CHAORONG ensures your farm stays operational during peak demand periods.

Would you like me to create a breakdown of the specific software tools needed to manage a multi-printer fleet effectively?

Small businesses are no longer just prototyping; they are out-scaling industry giants using 3D print farms. By leveraging a decentralized, modular approach to production, these “underdogs” are achieving a level of agility and ROI that legacy manufacturers cannot match.

What is a 3D Print Farm?

A 3D print farm is a collection of multiple 3D printers—ranging from ten to several hundred—working in parallel to produce parts at scale. Unlike a single industrial machine that costs $500,000, a farm utilizes consumer or “prosumer” hardware to create a redundant, scalable manufacturing ecosystem.

Why 3D Print Farms Beat Traditional Manufacturing

Traditional manufacturing relies on Economy of Scale, where cost decreases only when volume is massive. Print farms operate on Economy of Agility.

- Zero Tooling Costs: No need for $20,000 steel molds.

- Instant Iteration: Change a design file and the entire “factory” updates instantly.

- Risk Mitigation: If one machine breaks, 95% of your factory is still running. If an injection mold breaks, production stops.

Scalability and ROI: The Numbers

For small businesses, the ROI of a print farm is driven by the low cost of entry and the ability to scale linearly. You do not need a massive capital injection to start; you can grow the farm as orders increase.

Comparison: Print Farm vs. Injection Molding

| Feature | 3D Print Farm (Small Business) | Injection Molding (Traditional Giant) |

| Upfront Cost | Low ($5,000 – $20,000) | High ($50,000+) |

| Lead Time | 24 Hours | 6–12 Weeks |

| Design Flexibility | Infinite (Change daily) | Fixed (Molds are permanent) |

| Break-even Point | 1–1,000 Units | 10,000+ Units |

| Maintenance | Modular / DIY | Specialized / Expensive |

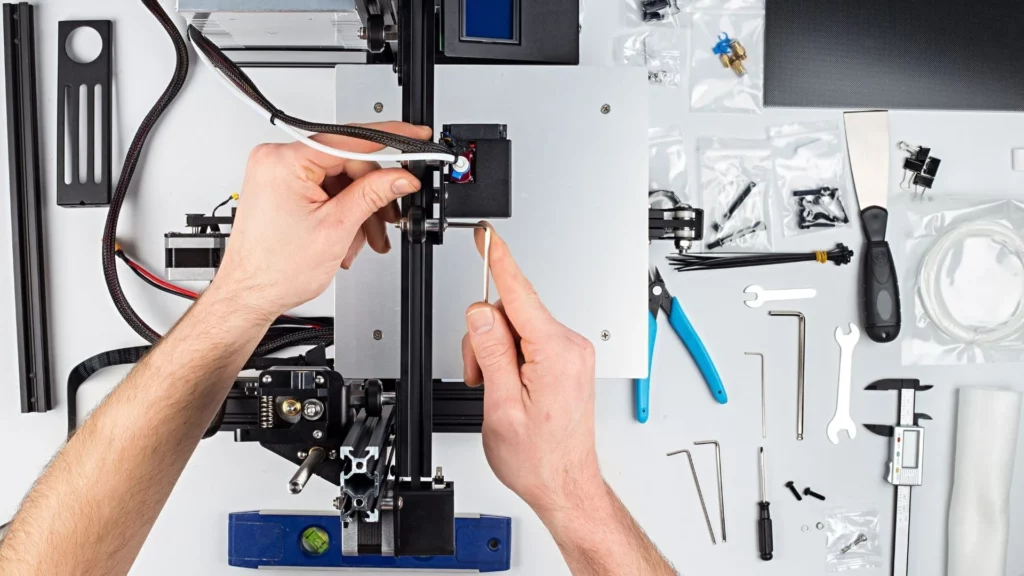

Hardware Essentials for a Scalable 3D Print Farm

To compete with giants, your farm needs reliable, “workhorse” machines. Reliability is the primary currency of a print farm manager.

1. High-Volume Production: Creality

Creality has become the industry standard for farm scaling due to its affordability and massive community support. The Ender and K1 series allow businesses to deploy 10 machines for the price of one industrial unit.

- Best for: General parts, enclosures, and high-volume PLA/PETG production.

- Resource: Explore Creality’s latest production-grade printers.

2. High-Precision Scanning: 3DMakerpro

Scaling often requires reverse engineering or digitizing physical assets. 3DMakerpro provides the high-fidelity scanning necessary to bring physical objects into the digital workflow with industrial accuracy.

- Best for: Quality control, reverse engineering, and custom-fit components.

- Resource: View 3DMakerpro Global scanning solutions.

3. Specialized Components: HONG KONG CHAORONG

For specific niche components and specialized 3D printing hardware that keeps a farm running at peak efficiency, sourcing from established distributors is vital for maintaining the supply chain.

- Resource: See HONG KONG CHAORONG specialized hardware.

Friendly Questions

How many 3D printers make a farm?

A 3D print farm typically starts at 5 to 10 machines. This is the point where manual management becomes difficult and professional farm management software (like OctoFarm or Repetier-Server) becomes necessary to maintain efficiency.

Is 3D printing cheaper than injection molding?

3D printing is cheaper for small to medium batches (up to 2,000 units). Once a product reaches mass-market volumes (10,000+ units), the per-unit cost of injection molding eventually drops below that of 3D printing.

What is the average ROI for a 3D print farm?

Most small business print farms report an ROI within 6 to 14 months. This is achieved by eliminating warehouse costs (print-on-demand) and avoiding the high “sunk costs” of traditional manufacturing tooling.

Building Your Edge: The Step-by-Step

- Identify a Niche: Don’t compete on generic goods. Focus on specialized “long-tail” products (e.g., drone parts, ergonomic tools, medical jigs).

- Standardize Your Fleet: Don’t mix ten different brands. Stick to one ecosystem, like Creality, to simplify maintenance and spare parts inventory.

- Automate Post-Processing: The “hidden cost” of a farm is labor. Invest in automated cleaning and curing stations.

- Iterate via Scanning: Use 3DMakerpro tools to ensure your printed parts match your digital specifications exactly, maintaining the E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) standards your customers expect.

For more deep dives into specific hardware configurations, visit our guides at 3dprintingbykevin.com.