Imagine a world where you can bring your wildest ideas to life at the push of a button. Sounds like magic, right? This is the reality of 3D printing. It’s a realm where imagination meets innovation, and it all starts with the fascinating materials used in 3D printing. Whether you’re new to the 3D printing universe or an eager beginner ready to dive in, understanding the materials is your first step. So buckle up, and let’s explore the wonders of 3D printing materials!

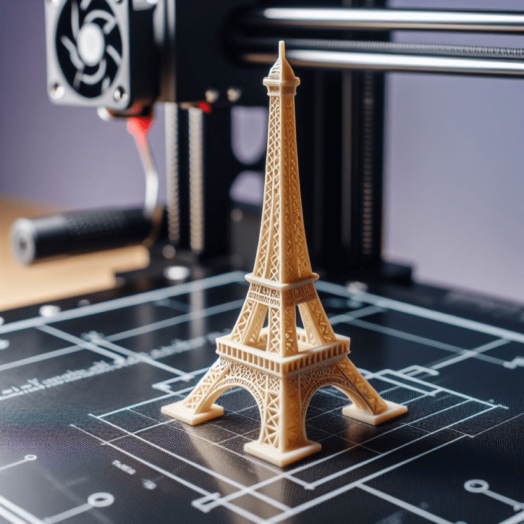

3D printing, or additive manufacturing, is a technology that builds three-dimensional objects from digital files. Unlike traditional methods that carve objects out of larger blocks of material, 3D printing creates items by adding material layer by layer, like a magician pulling a rabbit out of a hat. This approach opens up endless possibilities for creativity and innovation.

How Does a 3D Printer Work?

Picture a robot artist meticulously painting layer upon layer to form a sculpture. This is similar to how a 3D printer operates. A 3D printer starts with a design, which is a digital blueprint created using computer-aided design (CAD) software. This design is then sliced into thin layers, and the printer gets to work, crafting each layer one at a time until the object is complete.

Now, let’s embark on a journey to discover the different types of materials used in 3D printing. These materials are the secret ingredients that make 3D printing a marvel of modern technology. Adventurer 5M Pro – Get $30 Off with Code SA5MP! Now Only $569.00

Plastics: The Backbone of 3D Printing

When you think of 3D printing materials, plastics probably come to mind first. And rightly so! Plastics are the backbone of 3D printing, offering versatility, affordability, and ease of use.

PLA: The Eco-Friendly Champion

PLA, or Polylactic Acid, is the darling of 3D printing enthusiasts. It’s like the environmentally friendly superhero of the printing world. Made from renewable resources like cornstarch and sugarcane, PLA is biodegradable, making it a popular choice for eco-conscious creators.

Why Choose PLA?

– Easy to Use: PLA is user-friendly and perfect for beginners. It’s like a trusty sidekick that helps you learn the ropes of 3D printing.

– Low Warping: PLA cools quickly, which means less warping and more reliable prints.

– Vibrant Colors: Want to add a splash of color to your creations? PLA comes in a rainbow of vibrant colors, allowing your imagination to run wild.

ABS: The Sturdy Warrior

ABS, or Acrylonitrile Butadiene Styrene, is a sturdy warrior in the 3D printing arena. If you’ve ever played with LEGO bricks, you’ve held ABS in your hands. This material is known for its strength and durability, making it ideal for functional parts and prototypes.

Why Choose ABS?

– Strength: ABS is tough and durable, making it perfect for projects that need to withstand wear and tear.

– Heat Resistance: Need something that can handle a little heat? ABS has got you covered.

– Smooth Finish: With a little post-processing, ABS can achieve a smooth, polished finish.

PETG: The Best of Both Worlds

Meet PETG, the versatile material that combines the best qualities of PLA and ABS. Polyethylene Terephthalate Glycol (PETG) offers strength, flexibility, and ease of use. It’s like having the powers of both a superhero and a sidekick in one material.

Why Choose PETG?

– Durability: PETG is strong and impact-resistant, making it suitable for functional parts.

– Chemical Resistance: Need something that can withstand chemicals? PETG is up to the task.

– Minimal Warping: PETG has low warping, ensuring your prints come out just right. Adventurer 5M Fash Sale- Get $100 Off! Now Only $299. (US Only)

Metals: The Heavy Hitters

While plastics are popular, metals are the heavy hitters of 3D printing. They bring strength, durability, and a touch of luxury to the table.

Titanium: The Mighty Metal

Titanium is like the superhero of metals, known for its incredible strength-to-weight ratio. It’s used in industries like aerospace and medicine, where strength and lightness are critical.

Why Choose Titanium?

– Strength: Titanium is incredibly strong and can withstand extreme conditions.

– Lightweight: Despite its strength, titanium is surprisingly light, making it ideal for applications where weight matters.

– Biocompatible: Need something for medical implants? Titanium is biocompatible and safe for the human body.

Aluminum: The Versatile Virtuoso

Aluminum is a versatile virtuoso in 3D printing. It’s lightweight, corrosion-resistant, and perfect for a variety of applications.

Why Choose Aluminum?

– Lightweight: Aluminum is light, making it suitable for parts that need to be strong yet easy to handle.

– Corrosion Resistance: Aluminum can withstand the elements, making it ideal for outdoor use.

– Thermal Conductivity: Need something to manage heat? Aluminum’s thermal conductivity makes it a great choice.

Stainless Steel: The Reliable Workhorse

Stainless steel is a reliable workhorse known for its strength, durability, and resistance to corrosion. It’s used in industries like automotive and aerospace for its reliable performance.

Why Choose Stainless Steel?

– Durability: Stainless steel is tough and can handle heavy loads and wear.

– Corrosion Resistance: It can resist rust and corrosion, making it suitable for harsh environments.

– Polishable: Want a shiny, polished finish? Stainless steel can be polished to a brilliant shine.

Resins: The Artists’ Choice

Resins are the artists’ choice, offering precision and detail that are perfect for intricate designs and fine details. They are often used in processes like stereolithography (SLA) and digital light processing (DLP). Filament and Resin for 3D Printer

Standard Resin: The Detail Master

Standard resin is the go-to material for high-detail prints. It’s like a sculptor’s chisel, allowing for precise and intricate designs.

Why Choose Standard Resin?

– High Detail: Standard resin captures fine details with precision, making it ideal for artistic and intricate designs.

– Smooth Surface: Prints come out with a smooth surface, reducing the need for post-processing.

– Variety of Colors: Resins are available in various colors, allowing for creative expression.

Flexible Resin: The Elastic Wonder

Flexible resin is the elastic wonder of 3D printing. It can bend and flex, making it perfect for applications requiring flexibility and durability.

Why Choose Flexible Resin?

– Flexibility: Need something that can bend and stretch? Flexible resin can handle the job.

– Durability: Despite its flexibility, this resin is durable and can withstand repeated use.

– Versatility: It’s suitable for a variety of applications, from wearables to functional parts.

Castable Resin: The Jewelry Maker

Castable resin is a jewelry maker’s dream. It’s designed for creating intricate designs that can be cast into metal, like casting a magic spell to create precious jewelry.

Why Choose Castable Resin?

– Precision: Castable resin captures fine details, perfect for intricate jewelry designs.

– Burnout Properties: It burns out cleanly, leaving a perfect mold for casting metal.

– Versatility: Ideal for creating molds for various types of jewelry and small metal parts.

Specialty Materials: The Innovators’ Playground

The world of 3D printing is constantly evolving, with new materials offering exciting possibilities. These specialty materials are like the playground for innovators, pushing the boundaries of what’s possible.

Carbon Fiber: The Strength Enhancer

Carbon fiber is a strength enhancer known for its high strength-to-weight ratio. It’s used to reinforce other materials, making them stronger without adding much weight. Adventurer 3 Pro 2 – Get $10 Off with Code SAS3P2! Now Only $339.00

Why Choose Carbon Fiber?

– High Strength: Carbon fiber adds strength without adding weight, making it perfect for high-performance applications.

– Lightweight: Despite its strength, carbon fiber is incredibly light, ideal for aerospace and automotive industries.

– Stiffness: Need something rigid? Carbon fiber offers exceptional stiffness and stability.

Wood Filament: The Natural Touch

Wood filament brings a natural touch to 3D printing. It’s like bringing a piece of nature into your creations, offering a unique texture and appearance.

Why Choose Wood Filament?

– Aesthetic Appeal: Wood filament gives prints a natural, wood-like appearance, adding warmth and charm.

– Easy to Use: It’s user-friendly and can be used with standard 3D printers.

– Customizable Finish: Like woodworking, you can sand, stain, or paint wood filament to achieve the desired finish.

Conductive Filament: The Electric Wizard

Conductive filament is the electric wizard of 3D printing. It can conduct electricity, opening up possibilities for creating functional electronic components.

Why Choose Conductive Filament?

– Conductivity: Need to create circuits or sensors? Conductive filament can conduct electricity.

– Versatility: It’s suitable for a range of applications, from wearables to electronic gadgets.

– Innovation: Conductive filament opens up new possibilities for integrating electronics into 3D prints.

Understanding Material Properties: What to Consider

When choosing materials for 3D printing, it’s important to consider the properties that will best suit your project. Think of it as choosing the right tool for the job. Here are some key factors to consider:

Strength and Durability

Consider the strength and durability needed for your project. If you’re creating a functional part that will undergo stress, choose a material known for its toughness, like ABS or carbon fiber.

Flexibility and Elasticity

For projects requiring flexibility, like wearable devices or flexible components, opt for materials like flexible resin or TPU (thermoplastic polyurethane).

Heat and Chemical Resistance

If your project will be exposed to heat or chemicals, select materials with high resistance, such as ABS or PETG. For metal prints, consider stainless steel or aluminum.

Surface Finish and Aesthetics

The appearance of your finished product matters, too! For a smooth, polished finish, consider using resins or post-processing techniques to enhance the surface of your prints.

Environmental Impact

If you’re environmentally conscious, choose materials like PLA, which are biodegradable and made from renewable resources.

Tips for Beginners: Getting Started with 3D Printing

Embarking on your 3D printing journey can be exciting and rewarding. Here are some tips to help you get started on the right foot:

Choose the Right Printer

Selecting the right 3D printer is like choosing the right bicycle for a ride. Consider factors like build volume, resolution, and the types of materials the printer can handle. Start with a beginner-friendly printer that suits your needs.

Experiment with Materials

Don't be afraid to experiment with different materials. Each material has unique properties and capabilities, so try a variety to discover what works best for your projects.

Learn the Software

Familiarize yourself with 3D modeling software and slicers. These tools are essential for designing and preparing your prints. Start with user-friendly software to build your skills.

Start with Simple Projects

Begin with simple projects to build your confidence and skills. As you gain experience, you can tackle more complex designs and challenges.

Join the Community

The 3D printing community is vibrant and supportive. Join online forums, attend workshops, and connect with other enthusiasts to share tips, ideas, and inspiration.

Troubleshooting Common Issues

Like any technology, 3D printing can come with challenges. Here are some common issues and how to troubleshoot them:

Warping

Warping occurs when the corners of a print lift off the print bed. To prevent this, ensure proper bed adhesion by using a heated bed and applying adhesives like glue sticks or tape.

Layer Shifting

Layer shifting happens when the layers of a print misalign. Check for loose belts or pulleys, and ensure your printer is on a stable surface to prevent vibrations.

Stringing

Stringing occurs when thin strands of material appear between printed sections. Adjust the retraction settings in your slicer to minimize stringing.

Under-Extrusion

Under-extrusion is when not enough material is extruded, resulting in weak or incomplete prints. Check the filament diameter, nozzle size, and extrusion settings to ensure proper flow.

The Future of 3D Printing: Endless Possibilities

As technology advances, the future of 3D printing holds endless possibilities. From printing entire houses to creating human organs, the potential is limitless. New materials and techniques continue to emerge, pushing the boundaries of what's possible and opening new doors for creativity and innovation.

3D Printing in Space

Imagine 3D printing in space! NASA is exploring the use of 3D printing to create tools and structures on the International Space Station, reducing the need to launch supplies from Earth.

Bio-Printing

Bioprinting involves creating living tissues and organs using 3D printing technology. This breakthrough could revolutionize medicine and transplantation, offering patients new hope.

Sustainable Manufacturing

3D printing has the potential to reduce waste and promote sustainable manufacturing. By using only the material needed and exploring biodegradable options, 3D printing can contribute to a greener future.

Embrace the Adventure

3D printing is a thrilling adventure that invites you to explore the realms of creativity and innovation. By understanding the different types of materials and their properties, you can unlock the full potential of this amazing technology. So go ahead, dive into the world of 3D printing, and let your imagination soar. The possibilities are endless, and the journey has just begun!

---

I hope this introduction to 3D printing materials and their properties sparks your interest and inspires you to start your 3D printing journey. If you have any questions or need further guidance, feel free to ask. Happy printing!

---

Bullwinkle

Unlock the Future with Flashforge 3D Printers and Resin Printers!

Are you ready to dive into the amazing world of 3D printing? Our latest blog post, "Beyond the Button: The Fascinating Materials of 3D Printing," is your gateway to understanding the incredible potential of 3D printing. And guess what? We have the perfect tools to get you started: Flashforge 3D printers and resin printers!

Discover Flashforge 3D Printers

Flashforge 3D printers are your ideal partners on this creative journey. Known for their reliability and ease of use, Flashforge printers are like having a creative superhero in your home or classroom. Here's why Flashforge is the way to go:

- User-Friendly Design: Whether you're a beginner or a seasoned pro, Flashforge printers are designed to be easy to use right out of the box.

- High Precision: Flashforge printers deliver high-quality prints with incredible detail. They make sure every layer is perfect.

- Versatile Printing Options: From plastic to specialty filaments, Flashforge printers handle a variety of materials, giving you the freedom to create whatever you can imagine.

Unleash Creativity with Resin Printers

If you're looking for even more detail and precision, resin printers are the answer. Perfect for artistic and intricate designs, resin printers bring your ideas to life with stunning accuracy. Here's what makes them special:

-Incredible Detail: Resin printers capture the finest details, perfect for models, jewelry, and miniatures.

- Smooth Finishes: Create prints with smooth surfaces, reducing the need for extra finishing work.

- Wide Range of Resins: Choose from standard, flexible, or castable resins to fit your project needs.

Why Choose Flashforge?

Flashforge is a leader in the 3D printing world, known for its innovation and quality. Here's why you should choose Flashforge:

- Award-Winning Technology: Flashforge has won numerous awards for its innovative designs and reliable performance.

- Great for All Skill Levels: Whether you're a student, teacher, hobbyist, or professional, Flashforge has a printer that suits your needs.

- Strong Community Support: Join a vibrant community of creators and get tips, ideas, and support from fellow enthusiasts.

Start Your 3D Printing Adventure Today!

Don't miss out on the excitement of 3D printing. Check out our blog post to learn all about the materials and properties you can work with, and start your adventure with Flashforge 3D printers and resin printers. Whether you're creating prototypes, art, or anything in between, Flashforge is here to help you turn your dreams into reality.

Visit our website now to explore our range of Flashforge 3D printers and resin printers. Your creative journey starts here—let's build something amazing together!

---

I hope this sparks your interest and encourages you to explore the fascinating world of 3D printing with Flashforge. If you need more information or have any questions, feel free to reach out!

contact@3dprintingbykevin.com