One year ago, I saw a 3D-printed motorsports car in the 24 Hours of Le Mans. Today, I’m proud to say that 3D Printing is revolutionizing motorsports. Here’s how it’s happening.

Source: 3D Printed Car additive-x.com

It’s been over a year since the author drove a 3D-printed car in the 24 Hours of Le Mans. And in that time, 3D Printing has made some incredible strides in the world of motorsports. Today, more and more teams are using 3D Printing to create parts for their cars. And it’s not just small parts either – entire cars are printed using this technology. 3D Printing revolutionizes motorsports because it allows teams to create lighter and stronger parts than standard components.

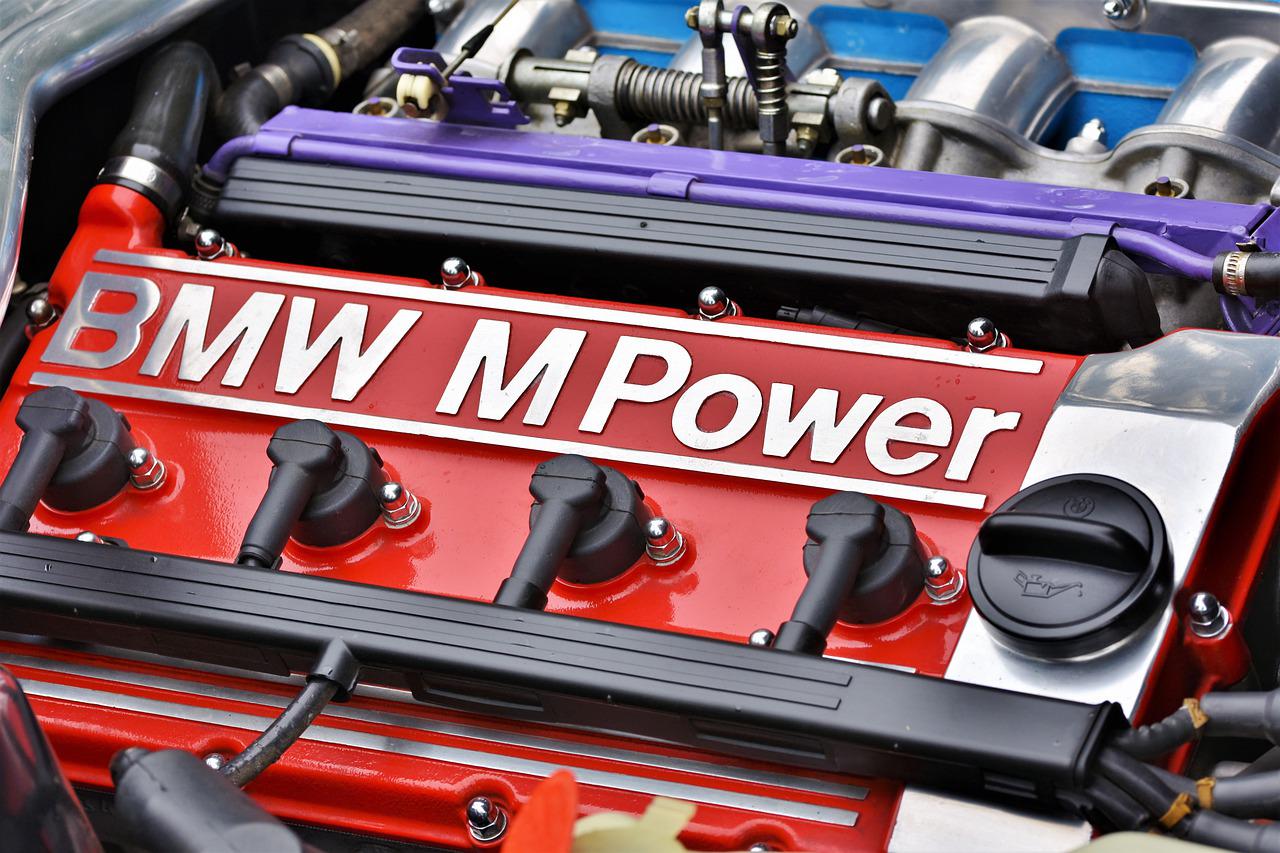

It is instrumental in endurance racing, where every tenth of a second count. In the past, the only way to make a part lighter was by taking material off of it, which also meant making it weaker. Now, it doesn’t have to be that way. The BMW i3 racer pictured below was 3D printed as a single piece, except for a few support structures.

Some 3D-printed parts are so precise and lightweight that they can provide the same level of performance as their traditional counterparts while also being 75% lighter. That’s the kind of innovation helping the entire industry become more competitive and pushes the limits of what’s possible in racing. But 3D Printing isn’t just changing the racing sport; it’s also changing how cars are designed.3D Printing allows teams to try new designs that would have been impossible with traditional manufacturing methods. And perhaps most importantly, 3D Printing will enable teams to develop and test new parts in days or weeks instead of months or years.

One year ago, the author drove a 3D-printed car in the 24 Hours of Le Mans. Signatech teamed up with Oak Ridge National Laboratory and Carbon for that race, who provided them with a Stratasys 3D printer. Allowing cars to go faster for extended periods is essential for top-level racing.

The future looks bright as the racing world moves away from traditional manufacturing techniques. As 3D Printing becomes more accessible, more teams will use it to their advantage. Perhaps we’ll see cars designed entirely on a computer and printed on demand. And by only using 3D printers, they can cut down on the amount of waste they produce.

- But how did things get to this point?

- How has 3D Printing become such a big part of motorsports?

- And what role can it play in the future?

To answer those questions, we need to look at the history of 3D Printing in motorsports. During the 1980s, Formula One teams started to use 3D Printing for prototyping.

Here’s how it’s happening:

Less than a decade ago, 3D Printing was a novel technology used mainly by hobbyists and enthusiasts. But in recent years, it has exploded in popularity and is now used in various industries, including motorsports. Why? Because 3D Printing offers customization and flexibility that traditional manufacturing methods can’t match. And as the technology continues to evolve and become more accessible, we’re likely to see even more applications for it in the racing world.

Origins of 3D Printing in Motorsports

3D Printing has been used in motorsports since the 1980s when Formula One teams started to use it to create prototypes. They’d scan the existing part on a full-size car and then get a 3D model to create a prototype.

What is 3D Printing?

Traditional manufacturing methods (machining, casting, etc.) involve:

- Transforming a lump of raw material into a finished product by cutting.

- Grinding.

- Melting away the unwanted bits.

This basic process has remained mostly unchanged for hundreds of years and serves us well. However, it does have a few flaws. First, this method tends to result in wasted material. For example, imagine a car part that is 3″ long.

3D Printing in Motorsports: the logistics

One of the biggest challenges that 3D Printing presents is the matter of logistics. 3D Printing allows you to create parts of any shape, size, and composition. But the process can be slow when it comes to printing those parts—even in a professional-grade 3D printer. The 3D printing process in motorsports is still in its infancy, and most applications are limited to prototyping. While some teams have a 3D printer on-site and utilize it to print replacement parts, most rely on local fabricators. Once the design is finalized, it is sent to a local fabricator for Printing. Then it’s on to the next race.

The practice is still far from mainstream, but several top F1 teams have started using it for prototyping. F1 cars are the most advanced racing vehicles in the world. Those teams experiment with some of the most cutting-edge automotive technologies. And since 3D Printing enables them to customize parts to minor details, that’s precisely what they’re doing. But this is just the tip of the iceberg.

Today, 3D Printing is Revolutionizing Motorsports.

Today, they are proud to say that 3D Printing is revolutionizing motorsports. It has helped create faster and more efficient cars, but it has also allowed for the development of new materials that can withstand extreme conditions. In the past, motorsports teams relied on trial and error to test new designs or make repairs. With 3D Printing, they can now create prototypes and test them on the track before committing. It allows for a much smoother development process and helps ensure that only the best products make it to the finish line.

3D-printed Parts are Taking Motorsports to the Next Level

While 3D Printing is revolutionizing motorsports, it would be an understatement to say it hasn’t come without its challenges. 3D printers have been known to have a high cost and low production speeds. But after years of development, the motorsports industry has now been able to use 3D Printing to its full potential.

Please look at the video above to see how 3D Printing makes its way into motorsports. And make sure to check out the first episode in our new series, “3D Printing: Fueled by Innovation,” to get a behind-the-scenes look at how 3D Printing is transforming this industry. Racing is not just about the cars, though. It’s also about the drivers. They are some of the most valuable assets a racing team can have. The vehicles are there to help them succeed, but their success is measured by the time it takes to get around the race track. Thanks to 3D Printing, these drivers can benefit from faster and more efficient cars.

Here are a few examples of how 3D Printing has changed motorsport design:

Improving the Design and Functionality of Existing Parts

One of the most significant benefits of 3D Printing is that it allows new ways of thinking about parts. Instead of breaking down a car into parts that only serve one function, 3D Printing has allowed the parts to be optimized for design and function. “This is a huge step forward,” states Hamilton. “It’s like a digital wind tunnel. The old analog wind tunnel is a complete dinosaur compared to this.”

Krzysztof Puszkarz, Vice President of Technology at GKN Aerospace, stated the same in an exclusive interview with 3DPrint.com.

We would love to know what you think of your new products. Would you do us a favor and leave a comment if you have a moment?

It enables us to improve upon everything we do. Still, it also helps us decide which products to research and review.

We’ve made leaving a comment or question easy! Just go below.

Some of the links in this article are affiliate links. If you were to buy something after clicking on one of these links, I would get a small commission that might help me get a new printer for the shop!

Thanks for being part of the community!

Bullwinkle

Hello,

As an eCommerce seller, the first physical touchpoint you’ll have with a customer is when your package arrives at their door, an impactful impression is critical.

Fulfillment marketing, a cutting-edge solution crafted by my friends over at The Fulfillment Lab, is designed to make the unboxing experience memorable by bringing marketing and fulfillment together at scale!

With this strategy, you can create a unique order fulfillment experience using data you’re already capturing—without sacrificing speed or scalability. It makes it possible to:

- Build brand recognition. With increasing competition for eCommerce businesses, you need a way to differentiate and build brand recognition. Fulfillment marketing is that solution!

- Tailor the customer experience. Personalize the fulfillment experience to each buyer using marketing data you’re already collecting—delivering a unique customer experience that’ll leave a lasting impression.

- Create brand advocates. Turn one-time buyers into repeat buyers and loyal advocates for your brand. You make it easier to attract new customers driving additional revenue from repeat sales while expanding your new customer base.

I figured you’d like to do this in your organization, so I’m connecting you with The Fulfillment Lab! Click this link [HERE] to get started with their fulfillment services today, or contact them directly if you have more questions.

The Fulfillment Lab, 5136 W Clifton St, Tampa, FL 33634, (813) 444-3455