Most people start 3D printing with Benchys, figurines, and calibration cubes. They look impressive, but they don’t change your finances. If you want real 3D printing ROI, the shift happens when your printer starts replacing store-bought items you already pay for.

Below are seven functional 3D prints that consistently save beginners and experienced users hundreds of dollars per month. These are practical, repeatable prints that justify owning a printer and turn it into a problem-solving tool instead of a novelty machine.What Are the Most Useful Functional 3D Prints?

The most useful functional 3D prints are replacement parts, storage solutions, home organization tools, automotive clips, custom mounts, and workshop accessories. These prints reduce repeat purchases, extend product life, and deliver immediate cost savings for beginners.

1. Replacement Parts (The Fastest ROI in 3D Printing)

Broken plastic parts are one of the biggest hidden expenses in everyday life. Appliance knobs, clips, hinges, and brackets often fail long before the product does. Manufacturers rarely sell these parts cheaply, if at all.

With a basic caliper and PLA or PETG, you can print replacement parts for pennies instead of buying entire assemblies.

If you print just two replacement parts per week, your printer has effectively paid for itself within months.

How to Measure and Design Replacement Parts for 3D Printing.

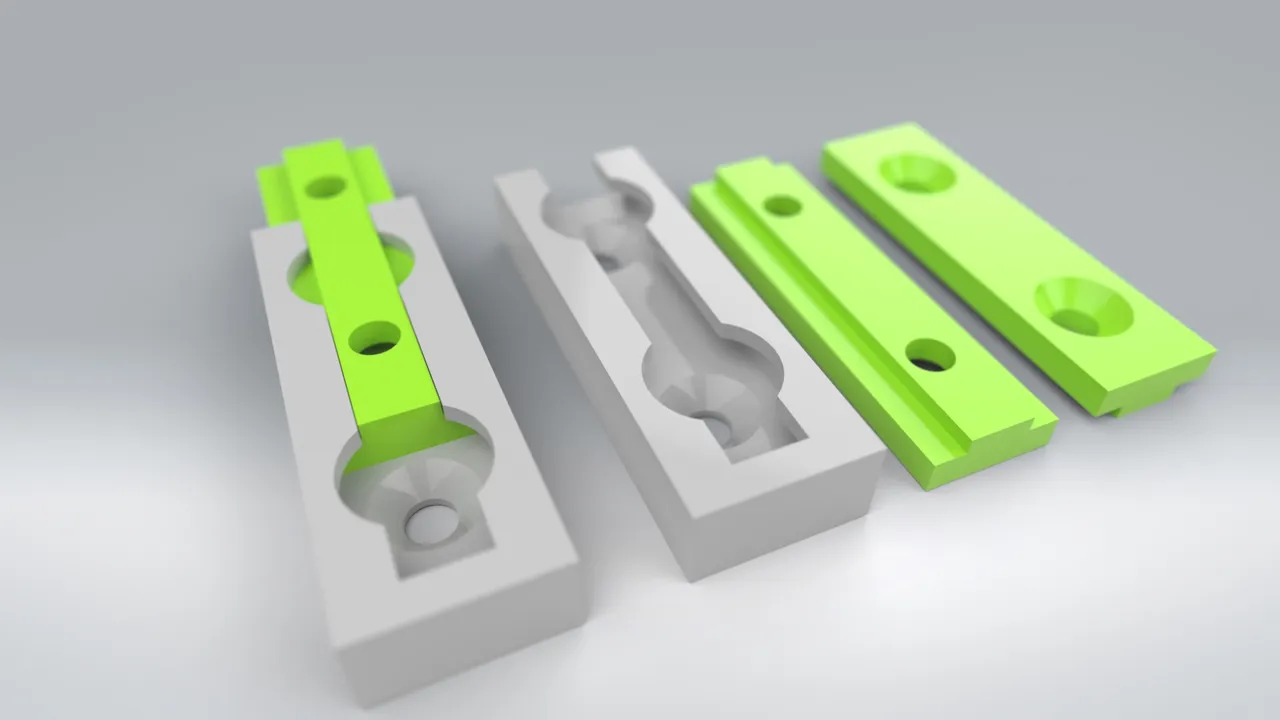

Creating replacement parts via 3D printing is a blend of precision metrology and functional design. The goal is not just to replicate the shape, but to ensure the new part survives the mechanical stresses of its intended environment.

Precise Measurement (The Input)

Before touching CAD software, you must capture the physical dimensions of the original part (or the space where it fits).

- Tools of the Trade: Digital calipers are essential for accuracy within ±0.02mm. For complex curves or organic shapes, a 3D scanner or thread gauges (for screws) are necessary.

- Critical Dimensions: Identify “mating surfaces”—where the part touches something else. These dimensions must be exact.

- Accounting for Wear: If the original part is broken or worn, measure the “negative space” of the assembly it fits into rather than just the damaged part itself.

Design for Additive Manufacturing (The Process)

Once you have your numbers, use CAD software (like Fusion 360 or Onshape) to model the part, keeping the unique constraints of 3D printing in mind.

- Tolerances and Clearances: 3D printers “squish” plastic, which can make holes smaller and pegs larger. Always design in a 0.2mm to 0.5mm clearance for parts that need to slide or fit together.

- Orientation and Strength: FDM prints are weakest along the “layer lines.” Design your part so that the primary stress pulls across the layers, not against the bond between them.

- Simplification: You don’t always need to copy the original perfectly. You can add “fillets” (rounded corners) or “gussets” (support ribs) to reinforce areas that previously failed.

Iteration and Testing

Rarely is the first print perfect.

- The “Fit Check”: Print a low-quality, fast version of just the connection points to verify the scale.

- Material Selection: Choose your filament based on the environment. Use PETG or ASA for outdoor/high-heat parts, as standard PLA will warp in a hot car or under heavy mechanical friction.

2. Modular Storage That Replaces Store-Bought Organizers

Retail organizers are expensive, fixed-size, and rarely fit your space perfectly. Modular 3D printed storage adapts to your drawers, shelves, and workflow.

Instead of buying new organizers every time your needs change, you print exactly what you need and expand later.

This is one of the most beginner-friendly ways to see immediate value from functional 3D prints.

→ Best Filaments for Functional Household Prints

3. Custom Mounts and Brackets (Stop Buying Universal Junk)

Universal mounts rarely fit perfectly. Custom 3D printed mounts eliminate compromises while avoiding overpriced accessories.

Whether it’s a router mount, monitor arm spacer, camera bracket, or smart-home holder, printing your own gives you precision and strength.

→ How to Print Strong Brackets Without Overengineering

4. Automotive Clips and Interior Parts

Automotive plastic clips are notoriously expensive for what they are. Dealerships sell them in bundles, and mechanics often replace entire panels because a single clip broke.

PETG or ABS prints handle automotive environments well when designed correctly.

Printing a small set of interior clips can save hundreds per repair.

→ Best Materials for Heat-Resistant 3D Prints

5. Workshop Tools You’d Otherwise Buy

Tool holders, drill guides, alignment jigs, and spacers add up quickly at hardware stores.

Printing them on demand keeps your workspace organized without unnecessary purchases.

Many beginners recover their printer cost just by printing workshop accessories over time.

→ Essential Functional Prints Every New 3D Printer Owner Should Make

6. Household Fixes That Prevent Bigger Expenses

Small failures often lead to big damage. A missing furniture foot scratches floors. Loose cables damage ports. A door slams and cracks trim.

These low-material prints quietly prevent expensive repairs.

This is where 3D printing for beginners starts feeling indispensable.

7. Selling or Sharing Prints Locally

Once friends or neighbors see what you can fix, requests follow. Charging modestly for replacement parts or custom organizers offsets filament costs fast.

This is how many people transition from hobby printing to real-world utility.

→ Can You Still Make Money 3D Printing in 2026?

Comparison: Hobby Prints vs Functional Prints

Beginner FAQ

Do functional 3D prints really save money?

Yes. Replacing just a few store-bought items per month often saves more than the cost of filament and electricity combined.

What printer is best for functional 3D prints?

Reliability, dimensional accuracy, and material compatibility matter more than speed. Well-tuned consumer printers are more than capable.

What materials should beginners use?

PLA for indoor parts, PETG for durability and moisture resistance, and ABS for higher-temperature environments when enclosed.

Ethical Tool & Hardware Recommendations

To print functional parts reliably, consistency matters more than hype. A stable machine, accurate motion system, and predictable extrusion are key.

If you’re upgrading or buying your first printer, I recommend reviewing:

These links are included transparently and support this site without changing your cost.