Speed is the flex everyone notices. Quality is the flex that actually sells prints, wins contests, and stops you from rage-restarting the same job at 2 a.m.

Here’s the surprising truth most makers learn the hard way: slowing down your 3D printer often makes it feel more powerful. Not because it’s “doing less,” but because it’s finally doing the right things at the right pace—melting, flowing, cooling, and bonding in a way your plastic can actually keep up with.

Affiliate Disclosure: This post contains affiliate links. If you buy through these links, I may earn a commission at no extra cost to you. I only recommend tools and materials I’d use in my own workflow.

In this guide, you’ll see exactly what changes when you reduce speed, which problems it fixes instantly, when it’s a waste of time, and how to slow down intelligently so you get better prints without turning every job into an overnight marathon.

What happens when you slow a 3D printer down?

When you slow a 3D printer down, filament has more time to melt evenly, flow consistently, and cool before the next pass. This typically improves layer adhesion, surface finish, dimensional accuracy, overhangs, and small details. Slowing down also reduces ringing/ghosting because the machine experiences less vibration during direction changes. The tradeoff is longer print times, so the best results come from slowing only the moves that matter most—outer walls, top surfaces, bridges, and small layers.

Why “go faster” breaks prints (and why slowing down works)

3D printing isn’t only motion. It’s a choreographed argument between physics and your expectations.

Your hotend can only melt so much plastic per second. Your part cooling fan can only remove so much heat per second. Your frame can only change direction so aggressively before it starts vibrating like a tuning fork. And your filament can only behave like a predictable material within a certain temperature and flow window.

When you push speed beyond one of those limits, you don’t just get “slightly worse.” You get failure modes that look random unless you know what to watch for: inconsistent extrusion, smeared corners, rough top layers, weak overhangs, blobs at seams, or that classic “why do I have ripples on every vertical wall?” ringing.

Slowing down works because it restores timing. Plastic gets time to melt fully. Pressure in the nozzle stabilizes. Corners stop overshooting. Layers cool enough to support the next one. The printer stops trying to do 4 jobs at once with the reflexes of a caffeinated squirrel.

If you’re newer to all of this, start here first and come back: 3D Printing for Absolute Beginners.

The “slow down” results that surprise most makers

Let’s talk outcomes you can actually see—not vague “quality improvements,” but the exact changes you’ll notice on your next print.

1) Cleaner outer walls (and fewer “mystery” surface scars)

Outer walls are where speed shows up as texture. At high speeds, tiny pressure fluctuations and vibration get embossed into your print like a fingerprint. Slowing the outer wall speed (not everything) is one of the fastest ways to make prints look more expensive.

Common wins: smoother sheen, less waviness, crisper corners, and fewer zits around seams.

2) Better top layers (especially on functional prints)

Top layers are brutally honest. If flow is inconsistent or the nozzle is dragging slightly, you’ll see it as roughness, gaps, or scarring. Slowing down top solid infill and the final top layer gives filament time to lay flat and fuse evenly—especially with PLA and PETG.

3) Less ringing/ghosting on vertical faces

Ringing is basically your printer’s momentum leaving a calling card after every sharp corner. High acceleration and high speed make it worse. Slowing down reduces the energy in each direction change, so the frame vibrates less and those echo patterns fade.

4) Stronger overhangs and bridges

Overhangs fail when hot plastic doesn’t solidify fast enough to support itself. Bridges sag when the line doesn’t “set” before gravity wins. Slower speeds (and smarter cooling) help the filament stiffen before the next move pulls on it.

5) More accurate holes and better fit on assemblies

Fast printing can slightly distort small features because corners overshoot and extrusion pressure doesn’t settle quickly. Slowing the external perimeters and small-feature speeds improves dimensional accuracy—so screws fit better, snap-fits behave more predictably, and parts actually assemble without “persuasion.”

If you want a full end-to-end workflow for dialing in quality from model to finished part, this pairs well with: How to 3D Print Like a Pro: From Model to Masterpiece.

Speed vs. quality: the real tradeoffs (and what’s worth slowing)

Here’s the part most people miss: you rarely need to slow everything. The best profiles print fast where speed doesn’t matter and slow where quality is visually or mechanically sensitive.

| Print Move | What you gain by slowing it down | When it’s most worth it |

|---|---|---|

| Outer walls | Smoother surfaces, sharper corners, less ringing visibility | Display parts, products, anything you photograph |

| Top layers | Flatter finish, fewer gaps/scars, better “premium” look | Functional prints, lids, covers, flat faces |

| Small perimeters | Cleaner details, fewer blobs, better dimensional accuracy | Text, logos, tiny holes, threads |

| Bridges/overhangs | Less sagging, cleaner undersides | Supports off, bridging tests, structural parts |

| Inner walls/infill | Usually minimal visible improvement | Only if you have under-extrusion or severe vibration |

In other words: slow the stuff your eyes and tolerances care about. Let infill and internal structure run faster unless your printer is struggling mechanically or your hotend can’t keep up with flow.

The hidden limiter: volumetric flow (why speed hits a wall)

Most “my printer can’t handle this speed” problems aren’t actually motion problems. They’re melt-and-flow problems.

Your slicer can request 120 mm/s, but your hotend may only melt enough filament for the equivalent of 8–15 mm³/s (varies by hotend, nozzle, temperature, and material). When the slicer asks for more plastic than the hotend can deliver, you get under-extrusion, weak layers, and rough surfaces—even if the motion system is rock solid.

That’s why slowing down can feel like magic: it drops your flow demand back into a stable zone. If you’d rather keep speed, you typically need to increase temperature carefully, switch to a higher-flow nozzle/hotend, or reduce line width and layer height. Otherwise, you’re asking your hotend to break thermodynamics with motivational quotes.

How to slow down the smart way (a practical tuning recipe)

Below is a straightforward method that improves quality fast without forcing you into an all-night print schedule. You can apply it in most slicers (Cura, PrusaSlicer, OrcaSlicer, etc.) because the concepts are universal—even if the exact setting names differ.

Step 1: Create a “Quality Pass” speed set (outer walls, top, small features)

Start by keeping your general print speed where you like it, then slow only:

Outer walls: try 25–45 mm/s

Top solid layers: try 20–35 mm/s

Small perimeters / small features: try 15–30 mm/s

Those ranges aren’t “rules.” They’re a reliable first pass for most consumer machines. The goal is to reduce vibration and stabilize extrusion where it shows most.

Step 2: Add minimum layer time for tiny parts

If you print small objects or tall skinny pieces, speed becomes a cooling problem. The nozzle comes back around before the previous layer solidifies, so edges droop or smear. A minimum layer time forces the printer to slow down (or pause) so the plastic can set.

This single change can make tiny prints look dramatically cleaner with PLA and reduce “melted” detail on PETG.

Step 3: Use slower bridges and controlled cooling

For bridges, slower is often better—but only if cooling is doing its job. If your bridges sag, reduce bridge speed and increase bridge fan (within reason for your material). PLA usually tolerates more fan. PETG can get stringy or brittle with too much fan, so you balance it.

Don’t forget: better bridges are also a design skill. If you’re modeling your own parts, strengthening a bridge with a small chamfer, arch, or rib can outperform any slicer trick. If you’re ready to build that skill set, this is a strong next read: Acquiring the Skills to Design 3D Objects Using Software.

Step 4: Calibrate before you blame speed

Speed amplifies calibration errors. If your extrusion is inconsistent at moderate speeds, slowing down might hide symptoms without fixing the cause. That’s why I treat calibration as the foundation and speed as the multiplier.

If you haven’t done a modern, practical calibration pass lately, do this first: The Calibration Trick That Makes Any 3D Printer Perform Better. Then apply speed tuning. You’ll get results that actually stick.

Scenarios: when slowing down is the fastest fix

Scenario A: Your print looks fine… until the top layer

This is classic “top surface is flow-sensitive.” Slow top solid infill and the final top layer. If you still see gaps, check extrusion calibration and consider a small temperature bump (5–10°C) only if your material can handle it without stringing.

Scenario B: You see ripples after corners (ringing/ghosting)

Slowing outer walls helps, but ringing often also involves acceleration and jerk (or “junction deviation,” depending on firmware). If you want the most noticeable improvement without deep firmware diving, slow outer walls and reduce acceleration for perimeters in your slicer if available.

Scenario C: PETG looks blobby and messy at “normal” speeds

PETG loves to ooze and doesn’t like being rushed on visible surfaces. Slow outer walls and top layers, reduce fan compared to PLA, and make sure retraction is sensible. Many makers get cleaner PETG by printing it slower than PLA and letting the material behave on its own terms.

Scenario D: Small text and details look melted

Use a slower “small perimeters” speed and enforce minimum layer time. If the detail is truly tiny, a smaller nozzle can help, but slowing down is the first lever because it improves precision without changing hardware.

Fast printing vs. slow printing

Not every printer behaves the same, but the patterns below are consistent across most well-built consumer FDM machines.

| Category | Faster printing tends to produce | Slower printing tends to produce |

|---|---|---|

| Surface finish | More visible texture, seams, and vibration artifacts | Smoother walls and cleaner top surfaces |

| Dimensional accuracy | More overshoot on corners and small holes | More consistent feature sizes and fit |

| Overhangs/bridges | More sagging if cooling can’t keep up | Cleaner edges and less droop |

| Strength (layer bonding) | Can drop if the hotend can’t melt enough material | More consistent bonding when flow is stable |

| Reliability | More sensitive to tuning, spool quality, and machine rigidity | More forgiving and repeatable results |

| Time | Shorter print duration | Longer print duration |

When slowing down is cheaper than upgrading hardware

If you’re reading this because you’re deciding whether to upgrade your printer, here’s a practical way to think about it.

Slow down first if your machine is generally reliable but quality is inconsistent at higher speeds. Speed tuning costs nothing and often gets you 80% of the “wow” improvement people chase with upgrades.

Consider hardware upgrades if you’re constantly hitting flow limits (under-extrusion at reasonable temps), you print a lot of large parts, or you’re trying to maintain high quality while increasing throughput. That’s when higher-flow hotends, better cooling, sturdier motion systems, and faster printers make sense.

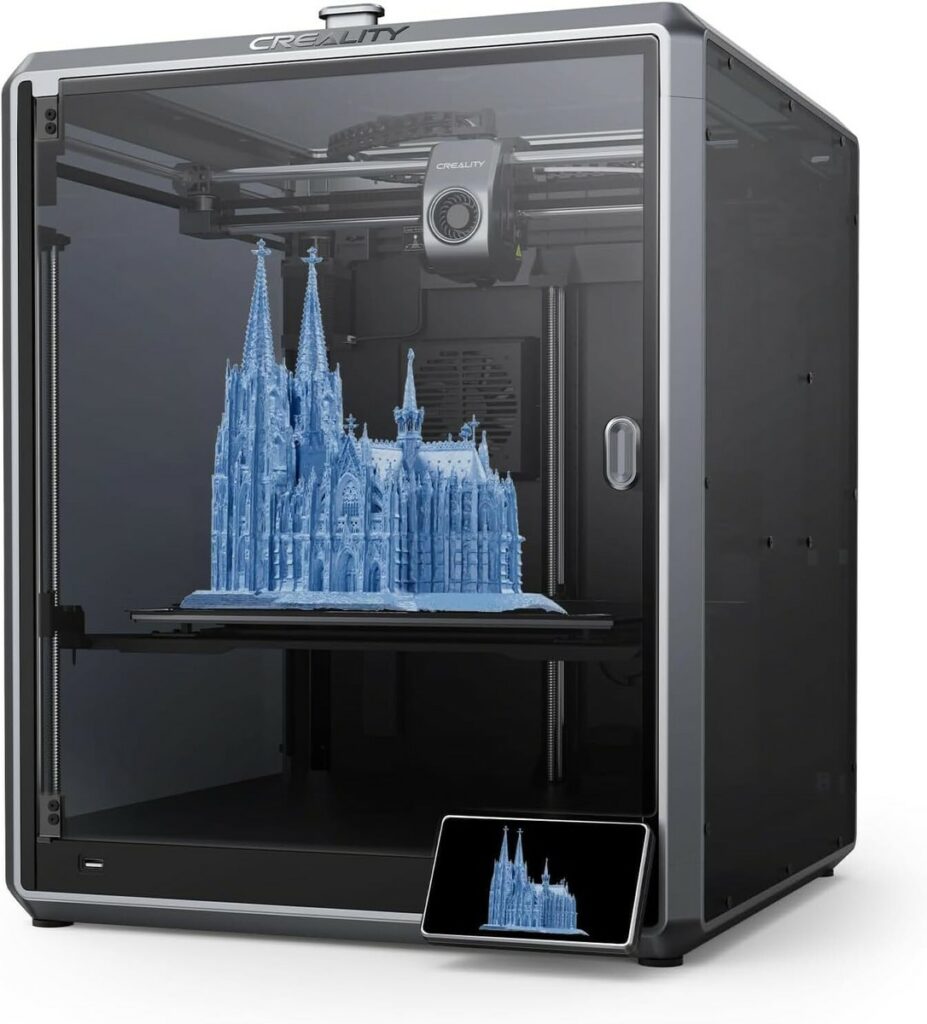

If you’re shopping or upgrading, Creality has a wide range of printers that can scale from “starter reliable” to “serious hobbyist output,” depending on model and configuration. If you want to browse current options, here’s my Creality link: Check current Creality deals and models.

And if part quality is the goal because you’re scanning objects to reproduce or modify them, a good 3D scanner changes the whole game. 3DMakerpro’s lineup is worth a look for makers building a scan-to-print workflow: Explore 3DMakerpro (Global) scanners.

Finally, don’t underestimate filament. A consistent spool can make “slow and beautiful” feel effortless. I use COEX when I want predictable diameter, clean extrusion, and repeatable results: Shop COEX with my link.

The fast checklist for better prints by slowing down

Make your next print look better in 10 minutes:

1) Set outer walls to 25–45 mm/s

2) Set top layers to 20–35 mm/s

3) Set small perimeters to 15–30 mm/s

4) Enable minimum layer time for tiny parts

5) Slow bridges and tune fan for your material

Then run a single test print you already know well. The goal isn’t perfection in one pass. The goal is to see which quality problems disappear instantly—because those are your “speed symptoms.”

Common mistakes when slowing down (that waste time without improving quality)

Mistake 1: Slowing infill and inner walls first. That’s rarely where quality problems come from. Put your time budget into outer walls, top layers, and small features.

Mistake 2: Ignoring temperature. If you slow down drastically without adjusting anything else, you can sometimes run a little hotter than necessary, which may increase stringing or blobs. Keep temperature sensible for your filament and let speed do the heavy lifting.

Mistake 3: Treating speed as a fix for poor calibration. Slow printing can hide issues like inconsistent extrusion or a partially clogged nozzle. If you keep needing “slower and slower” to survive, your printer is asking for calibration and maintenance, not a bedtime story.

FAQ: Slowing down your 3D printer

Does slowing down always improve print quality?

No. Slowing down improves quality when your current speed is pushing beyond your hotend’s melt capacity, your cooling capacity, or your machine’s vibration limits. If you’re already within stable limits, further slowing can add time without visible benefit. The best approach is targeted slowing: outer walls, top layers, bridges, and small features.

What speed should I use for high quality prints?

A reliable starting point is 25–45 mm/s for outer walls, 20–35 mm/s for top layers, and 15–30 mm/s for small features. Your best number depends on your printer’s rigidity, nozzle size, layer height, filament, and cooling. Tune using one controlled test print and change one variable at a time.

Will slowing down reduce stringing?

Sometimes. Slower moves can reduce pressure spikes and improve control, but stringing usually depends more on temperature, retraction, travel moves, and filament moisture. If you slow down and stringing increases, you may be printing hotter than necessary for that speed or your filament may be wet.

Should I slow down for PLA, PETG, and ABS?

PLA often benefits from slower outer walls and top layers for the cleanest finish, especially on detailed parts. PETG frequently needs slower visible surfaces to avoid blobs and messy seams. ABS can benefit from controlled speeds, but enclosure temperature management and warping control often matter more than speed alone.

What’s the best way to slow down without doubling print time?

Keep infill and inner walls relatively fast, and slow only outer walls, top layers, small features, and bridges. Add minimum layer time for tiny parts. This gives you most of the quality gains with a much smaller time penalty than slowing the entire print.

One last mindset shift that makes this click

Speed is a tool, not a personality.

When a print matters—when it needs to fit, look good, photograph well, or survive real use—slowing down isn’t “being cautious.” It’s choosing control over chaos. And once you get the hang of targeted slowing, you’ll notice something funny: you’ll still finish prints quickly… because you’ll stop reprinting the same part three times.

That’s the real surprise most makers discover. The fastest print is the one you only have to print once.